Energy-saving distillation and desalination system and method based on waste heat utilization of waste hot water in iron and steel plants

A technology of distillation and desalination and waste hot water, which is applied in the field of energy-saving distillation and desalination systems, can solve the problems of lack of process methods and recovery rate of less than 1%, and achieve the effects of reducing energy consumption, saving energy and reducing consumption significantly, and realizing energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

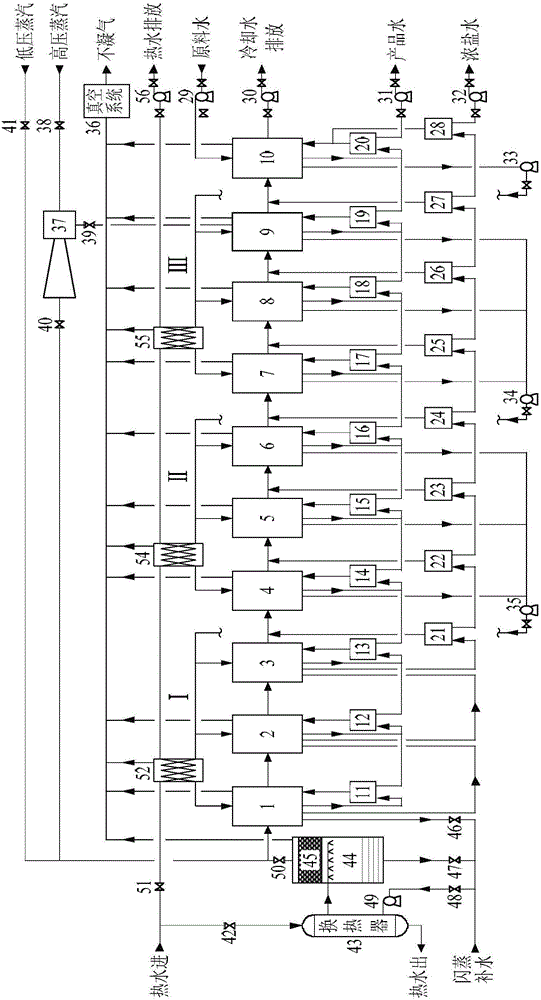

[0020] The present invention will be further described below by accompanying drawings.

[0021] In the following, the middle evaporation group (II) is one group, and the first evaporation group I is three evaporators. figure 1 1, 2, 3 respectively; middle evaporation group II is 3 evaporators, in figure 1 4, 5, 6 respectively; the last evaporation group III is 3 evaporators, in figure 1 are 7, 8, and 9 respectively; there are 9 product water flash tanks, in figure 1 Among them are 11, 12, 13, 14, 15, 16, 17, 18, 19 respectively; there are 7 concentrated brine flash tanks, in figure 1 Among them, 21, 22, 23, 24, 25, 26, 27 are respectively taken as an example to illustrate the present invention:

[0022] An energy-saving distillation and desalination system based on the utilization of waste hot water and waste heat in iron and steel plants, including the first evaporation group I, the middle evaporation group II, the last evaporation group III, condenser 10, product water fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com