Comprehensive recycling method of cobalt smelting high-magnesium ammonium sulfate wastewater

A high-magnesium ammonium sulfate and ammonium sulfate technology, which is applied in metallurgical wastewater treatment, cobalt compounds, ammonium sulfate, etc., can solve the problems of pollution, algae and other microorganisms in water, and achieve the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

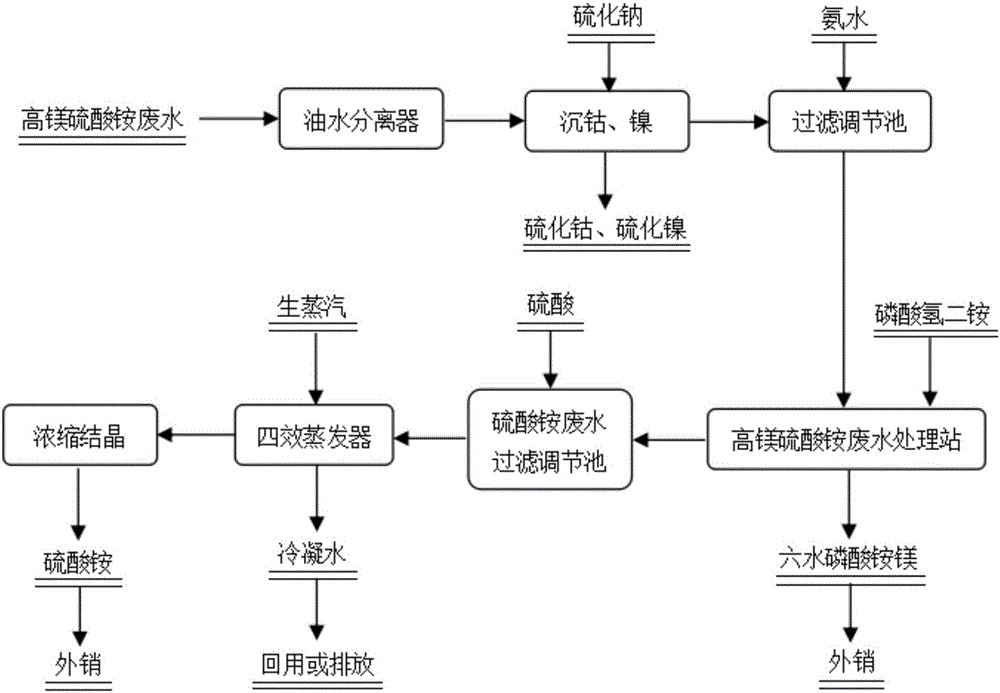

Method used

Image

Examples

Embodiment 1

[0021] Cobalt smelting high magnesium ammonium sulfate wastewater 400m 3 Selected from a metal smelting company in Gannan, where NH 4 + The content is 20g / l, the Co content is 0.03g / l, the Ni content is 0.5g / l, the Mg content is 4g / l, and the pH value is 5.

[0022] (1) After the above-mentioned high-magnesium ammonium sulfate wastewater is removed from the organic phase by an oil-water separator, a mixed solution A is obtained, and 220 kg of sodium sulfide is added to the mixed solution A, and 300 kg of a mixture of cobalt sulfide and nickel sulfide and filtrate A and filtrate A are obtained by filtration. into the cistern;

[0023] (2) the pH value of entering the water storage tank filtrate A in the step (1) is adjusted to 8 with ammoniacal liquor, then add diammonium hydrogen phosphate 1700kg, carry out solid-liquid separation, obtain solid 11000kg of magnesium ammonium phosphate hexahydrate and filtrate B;

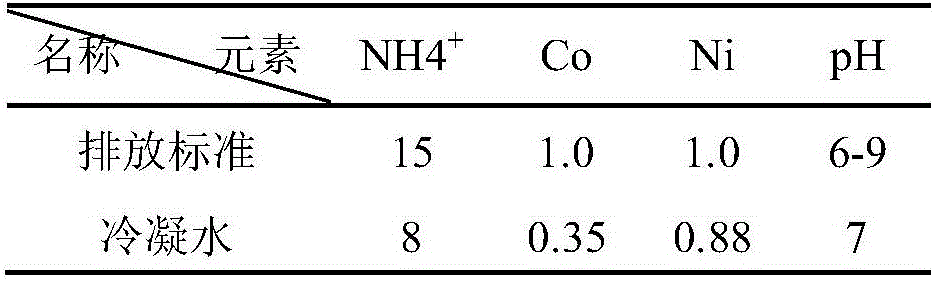

[0024] (3) Use sulfuric acid to adjust the pH of step (2) fil...

Embodiment 2

[0029] Cobalt smelting high magnesium ammonium sulfate wastewater 400m 3 Selected from a metal smelting company in Gannan, where NH 4 + The content is 28g / l, the Co content is 0.07g / l, the Ni content is 0.7g / l, the Mg content is 8g / l, and the pH value is 6.

[0030] (1) After the above-mentioned high-magnesium ammonium sulfate wastewater is removed from the organic phase by an oil-water separator, a mixed solution A is obtained, and 310 kg of sodium sulfide is added to the mixed solution A, and 420 kg of cobalt sulfide and nickel sulfide mixture and filtrate A and filtrate A are obtained by filtration. into the cistern;

[0031] (2) the pH value entering the water storage tank filtrate A in step (1) is adjusted to 10 with ammoniacal liquor, then add diammonium hydrogen phosphate 3200kg, carry out solid-liquid separation, obtain solid 20000kg of ammonium ammonium phosphate hexahydrate and filtrate B;

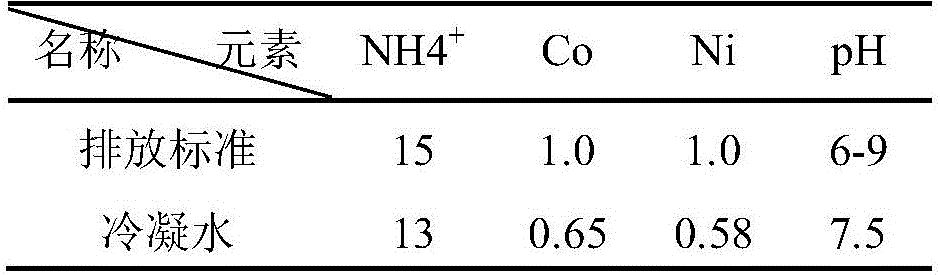

[0032] (3) Adjust the pH of step (2) filtrate B to 6.8 with sulfuric acid...

Embodiment 3

[0037] Cobalt smelting high magnesium ammonium sulfate wastewater 400m 3 Selected from a metal smelting company in Gannan, where NH 4 + The content is 26g / l, the Co content is 0.05g / l, the Ni content is 0.6g / l, the Mg content is 5g / l, and the pH value is 5.5.

[0038] (1) After the above-mentioned high-magnesium ammonium sulfate wastewater is pre-removed by an oil-water separator to obtain a mixed solution A, 260 kg of sodium sulfide is added to the mixed solution A, and 360 kg of a mixture of cobalt sulfide and nickel sulfide and filtrate A and filtrate A are obtained by filtration. into the cistern;

[0039] (2) the pH value entering the water storage tank filtrate A in the step (1) is adjusted to 9 with ammoniacal liquor, then add diammonium hydrogen phosphate 2000kg, carry out solid-liquid separation, get magnesium ammonium ammonium phosphate hexahydrate solid 15000kg and filtrate B;

[0040] (3) Use sulfuric acid to adjust the pH of step (2) filtrate B to 6.5, then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com