Method for directly preparing molding titanium matrix composite through titanium hydride powder

A titanium-based composite material and titanium hydride technology, which is applied in the field of non-ferrous metal processing, can solve the problems that the product density is difficult to meet the requirements of use, the production cost of titanium powder is high, and the requirements are strict, and achieve high density and mechanical properties. The effect of reducing environmental pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

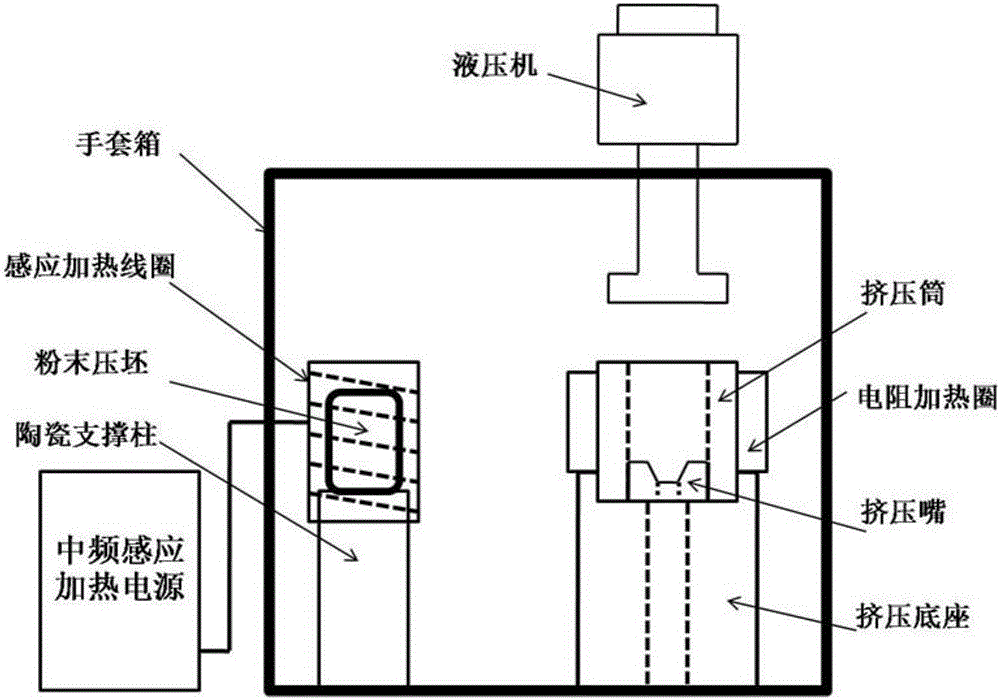

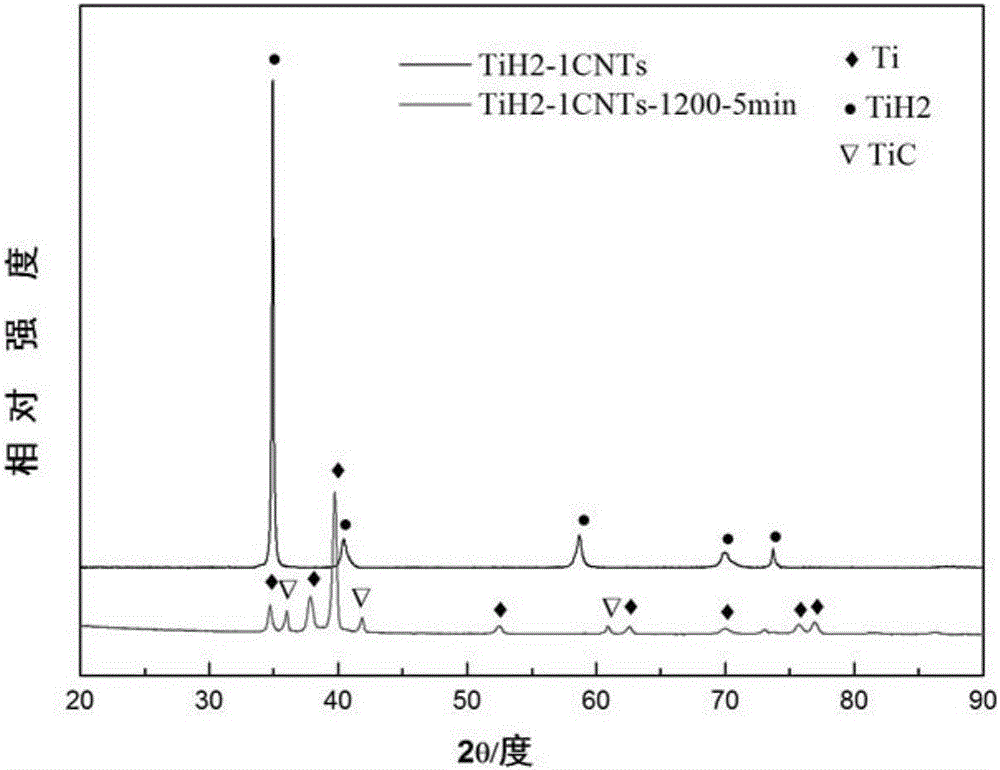

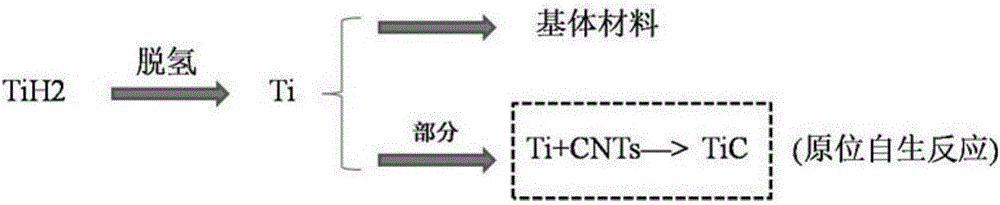

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention. Detailed implementation modes and specific operation procedures are given, but the protection scope of the present invention is not limited to the following Mentioned examples. The core of the present invention is to use titanium hydride as a raw material to combine titanium hydride dehydrogenation, in-situ reinforcement phase (or external reinforcement phase) and material consolidation in the same system. Any similar thermal consolidation process belongs to this The scope of protection of the invention.

[0042] Selection of raw materials:

[0043] In the invention, titanium hydride powder, an intermediate product in the process of preparing titanium powder by hydrogenation and dehydrogenation, is used as a base material, and its cost is greatly reduced compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com