Optical fiber tapering method and apparatus thereof

An optical fiber and optical fiber bundle technology, applied in the field of optical fiber communication, can solve the problems of reducing the heating effect, insufficient arc width, uneven heating in the coupling area, etc., and achieve the effect of improving the product qualification rate, improving the quality of the taper, and the effect of the taper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of method for optical fiber tapering is characterized in that the steps are as follows:

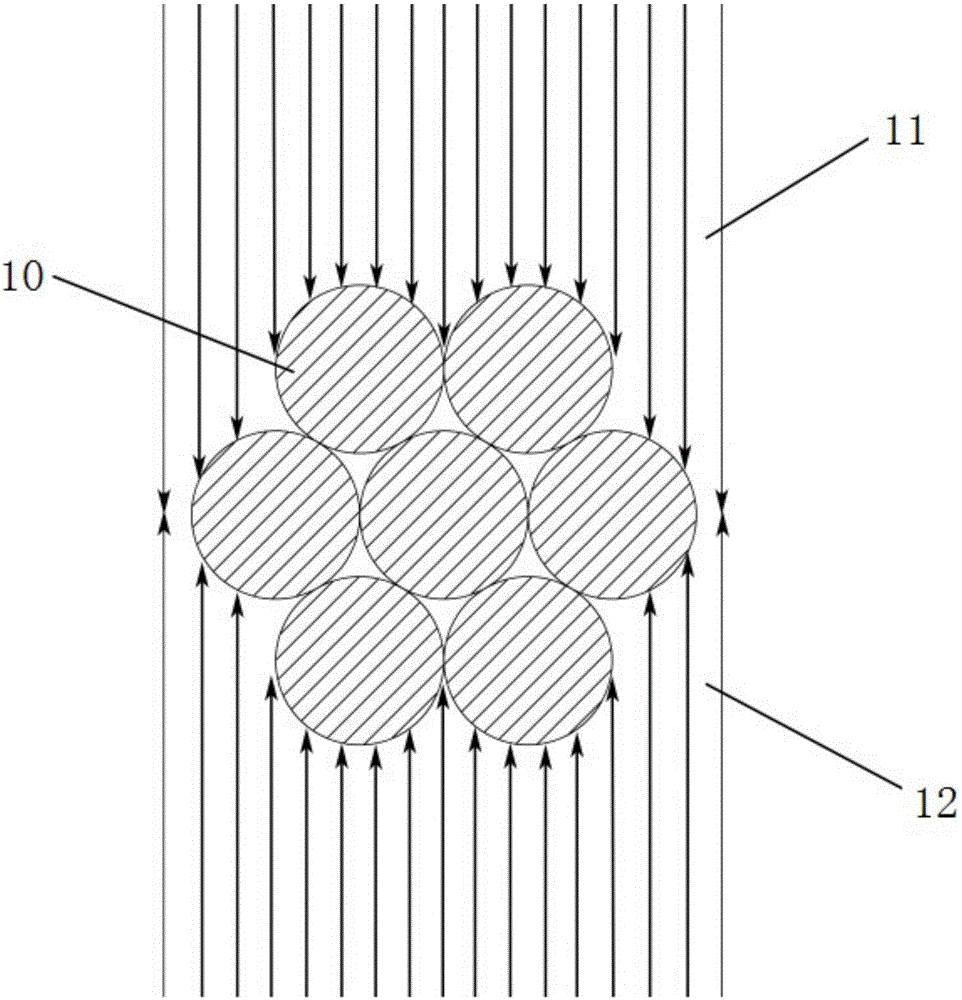

[0027] Step 1. Fix the two ends of the optical fiber bundle 10 to be processed on the first three-dimensional precision motion platform 81 and the second three-dimensional precision motion platform 82 respectively;

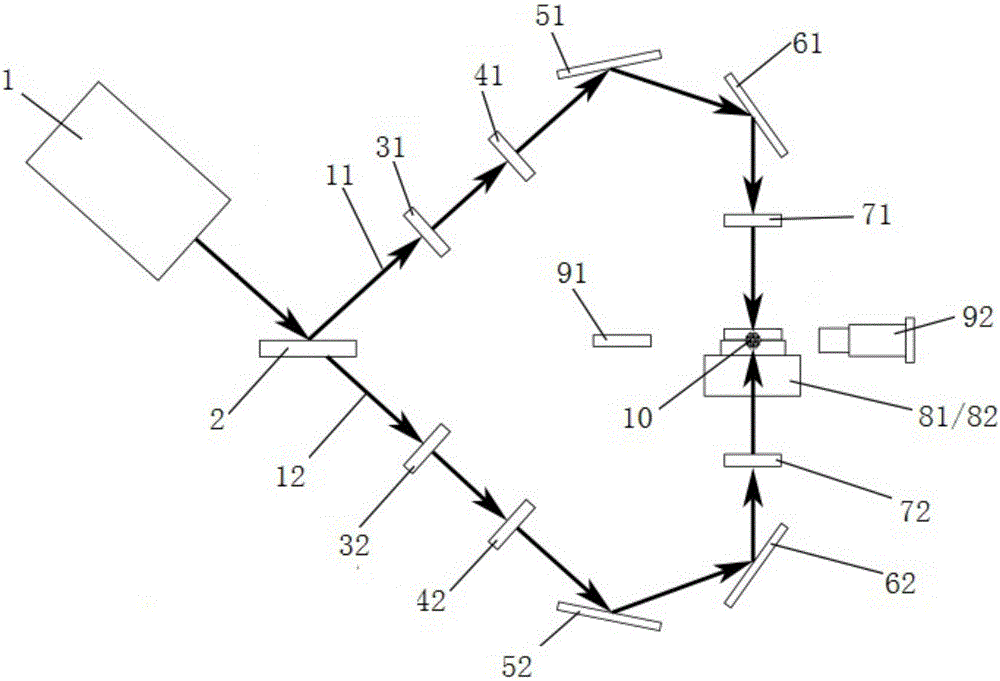

[0028] Step 2, using the beam splitter 2 to divide the laser beam emitted by the laser transmitter 1 into two beams, beam one 11 and beam two 12;

[0029] Step 3, the first total reflection mirror 51 is set on the path of beam one 11, the second total reflection mirror 52 is set on the path of beam two 12, and the positions of the first total reflection mirror 51 and the second total reflection mirror 52 are adjusted, Make beam one 11 and beam two 12 intersect on the area to be stretched of fiber bundle 10;

[0030] Step 4: Set the first collimating lens 31 and the first beam expander lens 41 between the beam splitter 2 and the first total reflection mirror 51,...

Embodiment 2

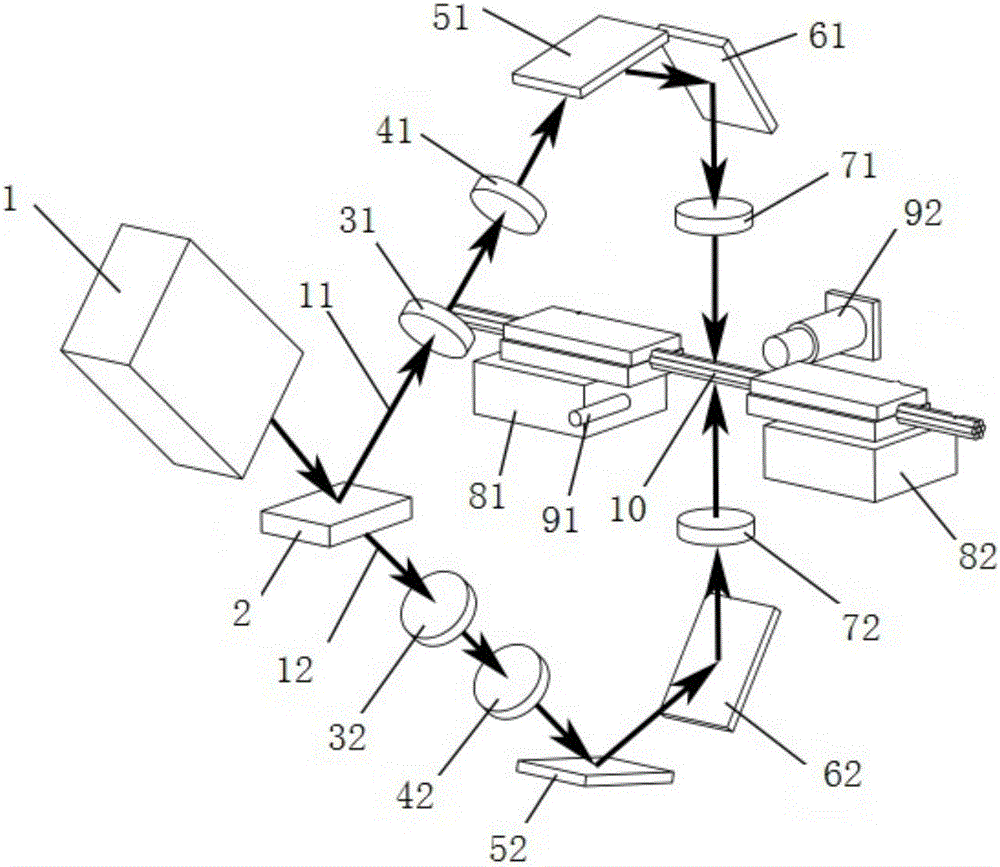

[0038] A kind of optical fiber tapering device, comprises the first three-dimensional precision motion platform 81, the second three-dimensional precision movement platform 82 and laser transmitter 1, is characterized in that: also comprises beam splitter 2, first total reflection mirror 51 and second total reflection mirror 52, the first total reflection mirror 51 and the second total reflection mirror 52 are respectively arranged on the optical path of the two beams of laser light emitted by the beam splitter 2, and the first quasi-reflection mirror 51 is arranged between the beam splitter 2 and the first total reflection mirror 51. Straight lens 31 and the first beam expander lens 41, the first collimating lens 31 is arranged between the beam splitter 2 and the first beam expander lens 41, is provided with the first field between the first total reflection mirror 51 and the fiber bundle 10 Mirror 71, the second collimator lens 32 and the second beam expander lens 42 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com