Graphene clad Fe2(MoO4)3 nanoparticle and preparation method and application thereof

A graphene-coated, nano-particle technology, applied in the field of Fe23 nano-particle preparation, achieves high specific capacity, high electronic conductivity, and is conducive to market promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Graphene-coated Fe 2 (MoO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0030] 1) Mix 20 mL of cyclohexanol and 20 mL of cyclohexane, and add 0.4 g of sodium lauryl sulfate to obtain a mixed solution.

[0031] 2) Dissolve 0.56g of ferric nitrate in 15mL of deionized water to obtain solution A, dissolve 0.37g of ammonium heptamolybdate in 15mL of deionized water to obtain solution B, and add A and B solutions to the mixed solution obtained in step 1) in turn Stir in.

[0032] 3) The product obtained in step 2) is centrifugally filtered, the obtained precipitate is repeatedly washed with deionized water and alcohol, and dried at 70° C. to obtain the nanowire precursor.

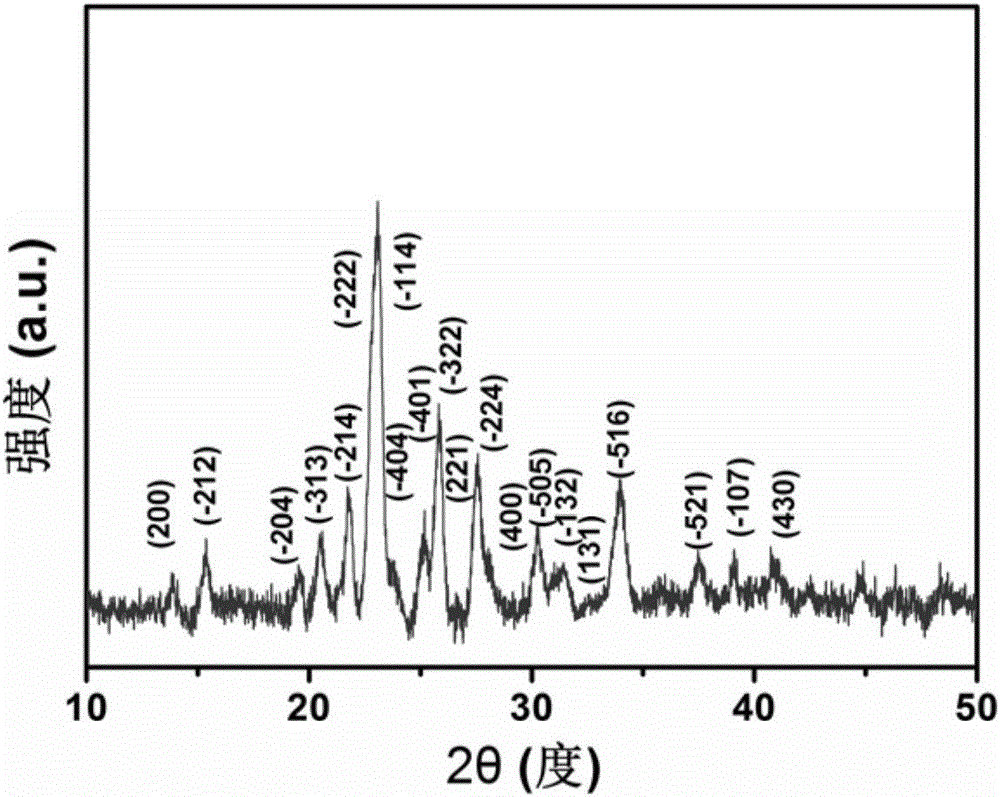

[0033] 4) Put the precursor obtained in step 3) into a muffle furnace, heat it up to 500°C in the air and keep it warm for 2 hours, then cool naturally to room temperature to obtain Fe 2 (MoO 4 ) 3 nanoparticles;

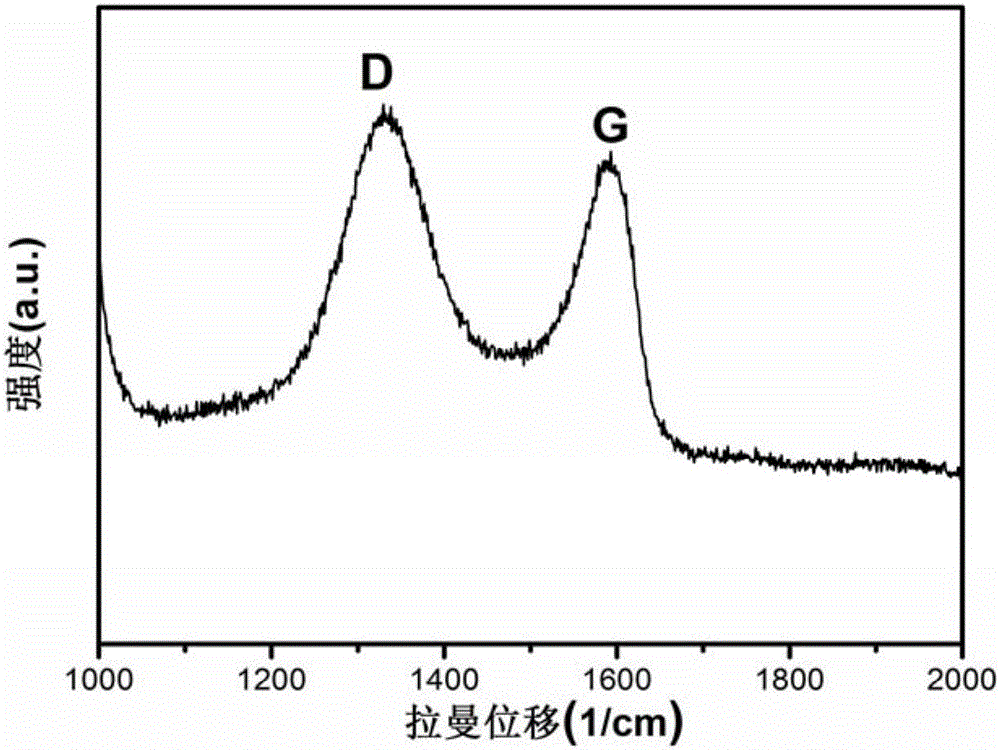

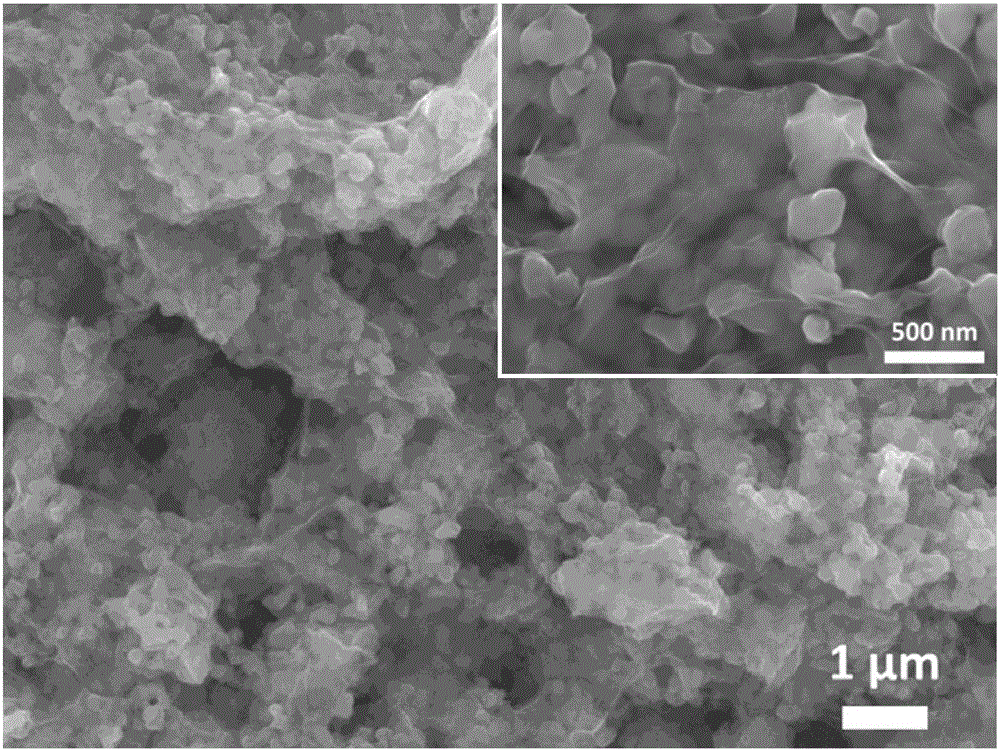

[0034] 5) Take 0.15 g of the ferric molybdate particles pr...

Embodiment 2

[0040] Graphene-coated Fe 2 (MoO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0041] 1) Mix 25 mL of cyclohexanol and 25 mL of n-pentanol, and add 0.3 g of cetyltrimethylammonium bromide to obtain a mixed solution.

[0042] 2) Dissolve 0.56g ferric nitrate in 15mL deionized water to obtain solution A, dissolve 0.37g ferric molybdate in 15mL deionized water to obtain solution B, and add A and B solutions to the mixed solution obtained in step 1) in sequence Stir.

[0043] 3) The product obtained in step 2) is centrifugally filtered, the obtained precipitate is repeatedly washed with deionized water and alcohol, and dried at 70° C. to obtain the nanowire precursor.

[0044] 4) Put the precursor obtained in step 3) into a muffle furnace, raise the temperature to 500°C in the air and keep it warm for 2 hours, then cool naturally to room temperature to obtain Fe 2 (MoO 4 ) 3 nanoparticles.

[0045] 5) Take 0.15 g of the ferric molybdate particles p...

Embodiment 3

[0050] Graphene-coated Fe 2 (MoO 4 ) 3 A method for preparing nanoparticles, comprising the steps of:

[0051] 1) Mix 15 mL of cyclohexanol and 15 mL of cyclohexane, add 0.3 g of sodium lauryl sulfate to obtain a mixed solution;

[0052] 2) Dissolve 0.56g of ferric nitrate in 15mL of deionized water to obtain solution A, dissolve 0.37g of ammonium heptamolybdate in 15mL of deionized water to obtain solution B, and add A and B solutions to the mixed solution obtained in step 1) in turn Stir in.

[0053] 3) The product obtained in step 2) is centrifugally filtered, the obtained precipitate is repeatedly washed with deionized water and alcohol, and dried at 70° C. to obtain the nanowire precursor.

[0054] 4) Put the precursor obtained in step 3) into a muffle furnace, heat it up to 500°C in the air and keep it warm for 2 hours, then cool naturally to room temperature to obtain Fe 2 (MoO 4 ) 3 nanoparticles.

[0055] 5) Take 0.15 g of the ferric molybdate particles prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com