Fabrication method for cover body of superhigh temperature ceramic matrix composite material ablation head antenna cover

A technology of ultra-high temperature ceramics and composite materials, applied in the direction of the radiation unit cover, can solve the problems of large ablation of the radome stagnation point, changing the aerodynamic shape of the radome, affecting the missile strike accuracy, etc., to shorten the preparation period and improve the impregnation. The effect of compounding efficiency and improving impregnation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

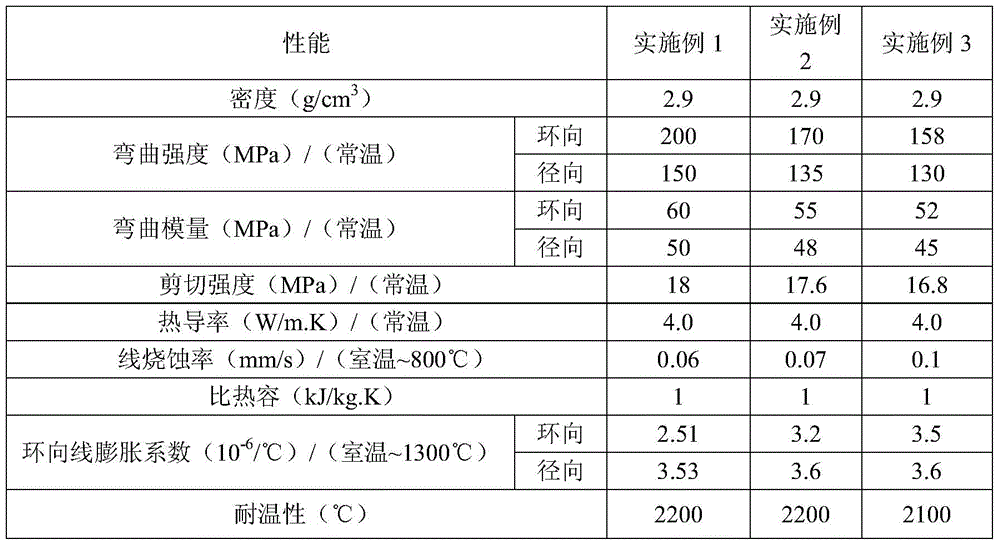

Embodiment 1

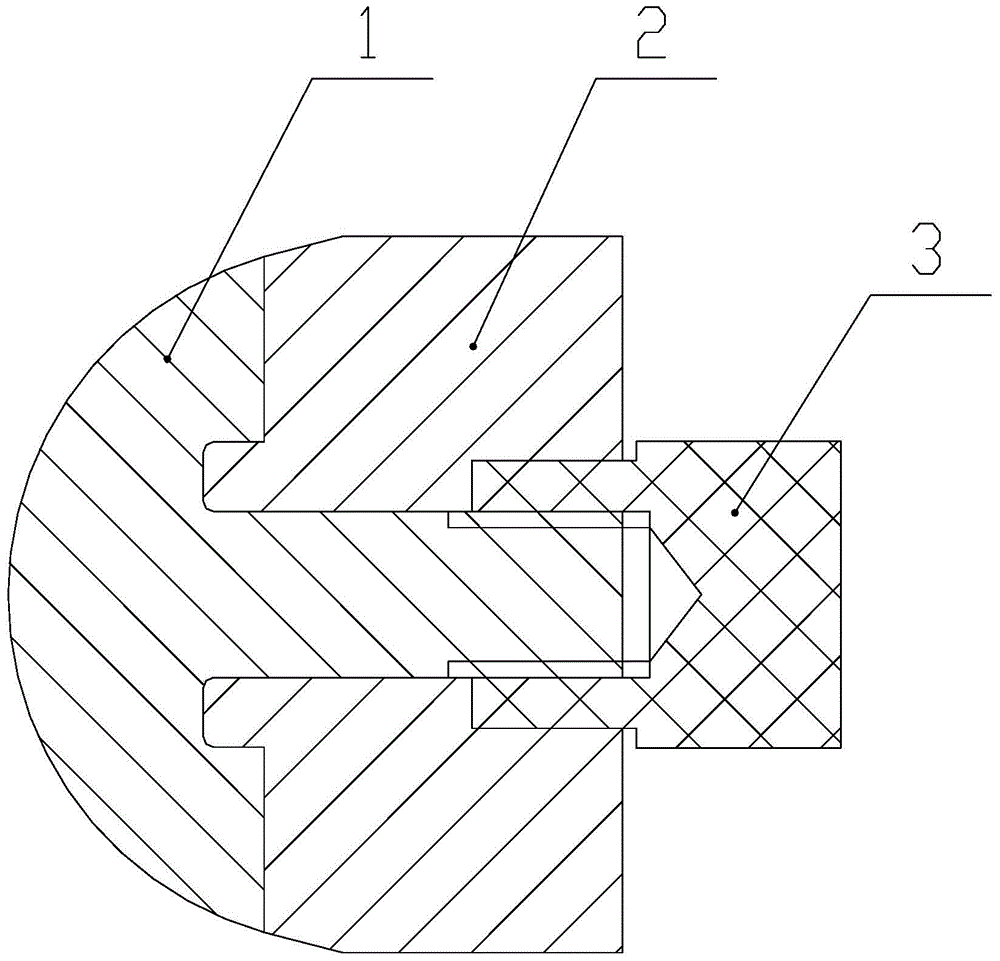

[0034] A method for manufacturing an ultra-high temperature ceramic matrix composite material ablation head radome cover body 1, comprising the following steps:

[0035] 1) Use the carbon fiber three-phase orthogonal method to weave the ablation head flat fabric to obtain the ablation head braid; weaving parameters: radial direction 3K×1, density 3 / cm, weft direction 3K×8, density 5 / cm , normal direction 3K×1, density 3 / cm

[0036] 2) Submerge the braided fabric of the ablation head in the precursor, heat it in a water bath to 80-100°C, vacuum impregnate it for 6 hours, take it out, dry and solidify it, repeat 3 times, and obtain the immersed braided fabric; wherein, the precursor is a bismuth containing polycarbosilane Toluene solution; polycarbosilane content in xylene solution is 50%;

[0037] 3) Add zirconia powder to the precursor and mix evenly; obtain a mixed solution, then immerse the submerged braid in the mixed solution, fully impregnate and compound; then perform v...

Embodiment 2

[0046] A method for manufacturing an ultra-high temperature ceramic matrix composite material ablation head radome cover body 2, comprising the following steps:

[0047] 1) Use the carbon fiber three-phase orthogonal method to weave the ablation head flat fabric to obtain the ablation head braid; weaving parameters: radial direction 3K×1, density 3 / cm, weft direction 3K×4, density 5 / cm , normal direction 3K×1, density 3 / cm

[0048] 2) Submerge the braided fabric of the ablation head in the precursor, heat it in a water bath to 80-100°C, vacuum impregnate it for 6 hours, take it out, dry and solidify it, repeat 3 times, and obtain the immersed braided fabric; wherein, the precursor is a bismuth containing polycarbosilane Toluene solution; polycarbosilane content in xylene solution is 50%;

[0049] 3) Add zirconium carbide powder to the precursor and mix evenly; obtain a mixed solution, then immerse the submerged braid in the mixed solution, fully impregnate and compound; then ...

Embodiment 3

[0057] The method for manufacturing the radome body 3 of the ablation head radome made of ultra-high temperature ceramic matrix composite material comprises the following steps:

[0058] 1) Use the carbon fiber three-phase orthogonal method to weave the ablation head flat fabric to obtain the ablation head braid; weaving parameters: radial direction 3K×2, density 3 / cm, weft direction 3K×4, density 5 / cm , normal direction 3K×2, density 3 / cm

[0059] 2) Immerse the braided fabric of the ablation head in the precursor, heat it in a water bath to 80-100°C, vacuum impregnate it for 6 hours, take it out, dry and solidify it, repeat 5 times, and obtain the immersed braided fabric; wherein, the precursor is a bismuth containing polycarbosilane Toluene solution; polycarbosilane content in xylene solution is 50%;

[0060] 3) Add zirconium carbide powder to the precursor and mix evenly; obtain a mixed solution, then immerse the submerged braid in the mixed solution, fully impregnate and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com