Photocatalytic material and preparation method and application thereof

A photocatalytic material and reaction technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, catalysts for physical/chemical processes, etc. Favorable for electron transfer, wide absorption range, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, the photocatalytic material is prepared by the following method, which specifically includes the following steps:

[0051] (1) Take 20 μL of 5nM gold nanorod stock solution, add water to 1 mL, centrifuge to remove the supernatant, and add cetyltrimethylammonium bromide (CTAB) solution with a concentration of 50 mM to the precipitate to 1 mL;

[0052] (2) Prepare a 1000 μM cysteine solution, add 100 μL of the solution to the solution in step (1), and place it in a water bath at 30° C. for 24 hours;

[0053] (3) After the water bath is completed, centrifuge the mixed solution, remove the supernatant, add water to 1 mL, and then add concentrated ammonia water (25% to 28%) to adjust the pH to 12; 10 μL of tetraisopropyl titanate (TTIP ) into 10 mL of isopropanol and mix evenly, take 10 μL of the mixed solution and add it to the solution of step (3), shake slightly, and react for 24 hours to obtain the photocatalytic material.

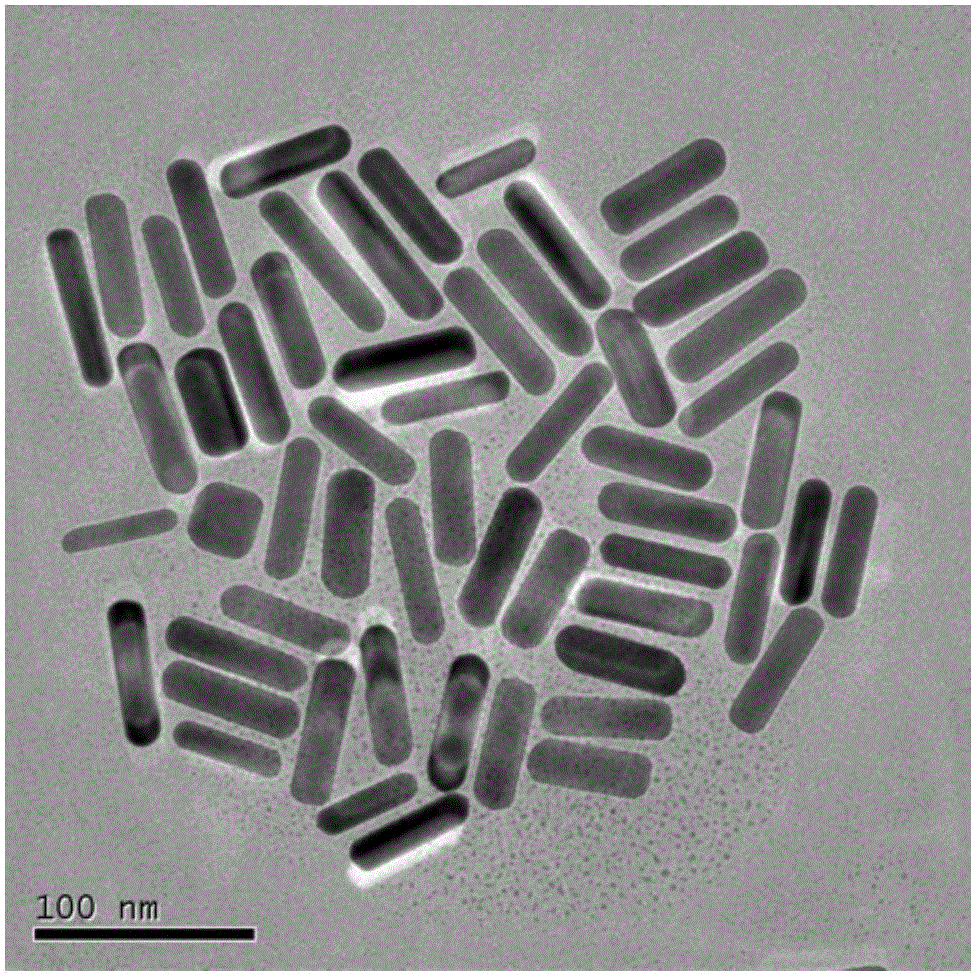

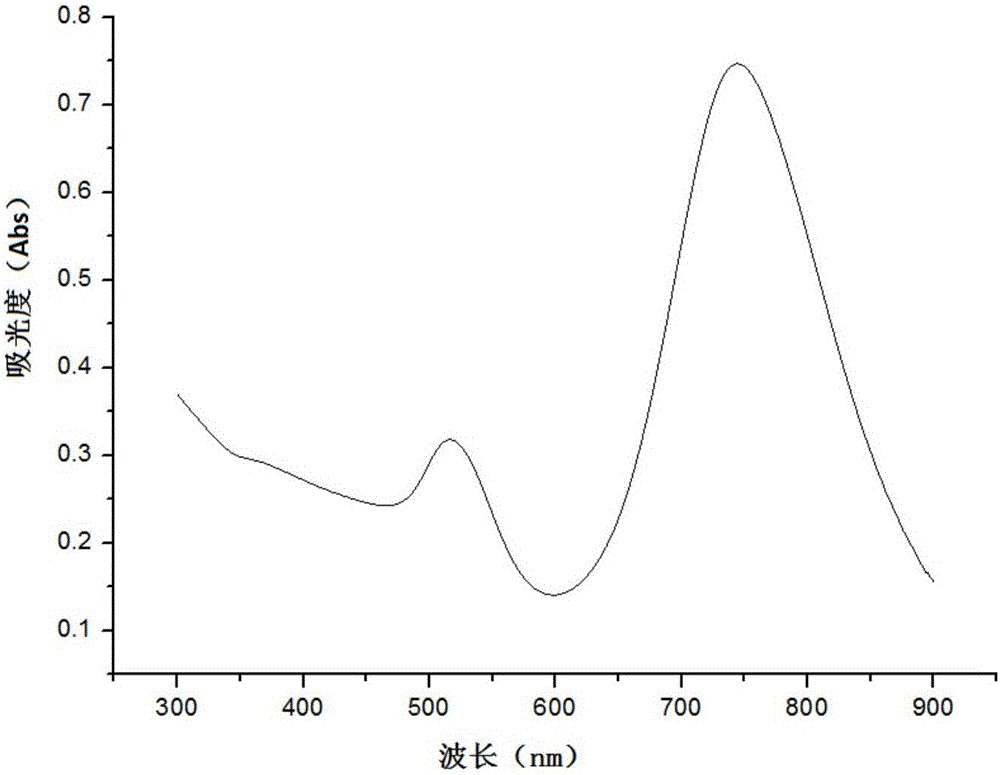

[0054] Utilize transmis...

Embodiment 2

[0057] In this embodiment, the photocatalytic material is prepared by the following method, which specifically includes the following steps:

[0058] (1) Take 20 μL of 5nM gold nanorod stock solution, add water to 1 mL, centrifuge to remove the supernatant, and add cetyltrimethylammonium bromide (CTAB) solution with a concentration of 10 mM to the precipitate to 1 mL;

[0059] (2) Prepare a 500 μM reduced glutathione solution, add 100 μL of the solution to the solution in step (1), and then place it in a water bath at 30° C. for 24 hours;

[0060] (3) After the water bath is completed, centrifuge the mixed solution, remove the supernatant, add water to 1 mL, and then add concentrated ammonia water (25% to 28%) to adjust the pH to 11; 10 μL of tetraisopropyl titanate (TTIP ) into 10 mL of isopropanol and mix evenly, take 10 μL of the mixed solution and add it to the solution of step (3), shake slightly, and react for 24 hours to obtain the photocatalytic material.

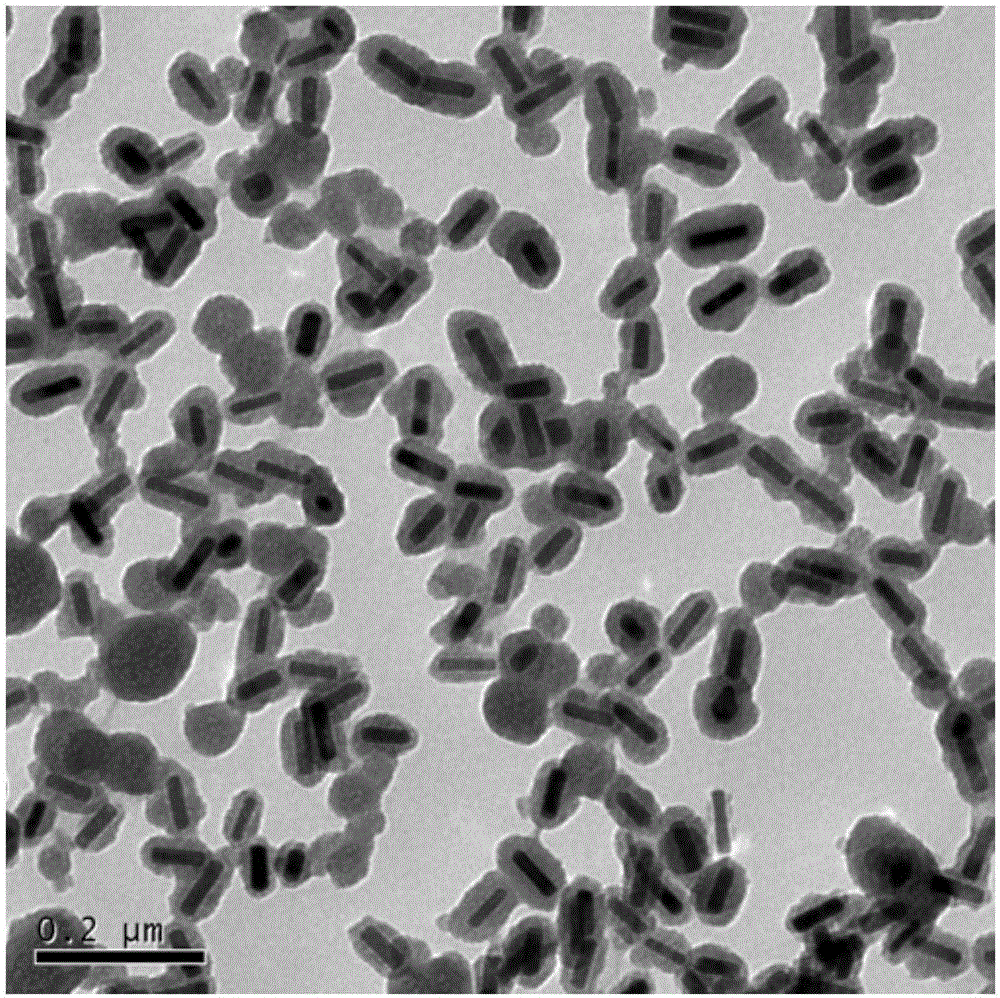

[0061] The...

Embodiment 3

[0063] In this embodiment, the photocatalytic material is prepared by the following method, which specifically includes the following steps:

[0064] (1) Take 20 μL of 5nM gold nanorod stock solution, add water to 1 mL, centrifuge to remove the supernatant, and add cetyltrimethylammonium bromide (CTAB) solution with a concentration of 50 mM to the precipitate to 1 mL;

[0065] (2) Prepare a 1000 μM cysteine solution, add 100 μL of the solution to the solution in step (1), and then place it in a water bath at 30° C. for 24 hours;

[0066] (3) After the water bath is completed, centrifuge the mixed solution, remove the supernatant, add water to 1 mL, then add concentrated ammonia water (25% to 28%) to adjust the pH to 11; dissolve 10 μL of tetrabutyl titanate (TBOT) Add it into 20 mL of isopropanol and mix evenly, take 10 μL of the mixed solution and add it to the solution in step (3), shake slightly, and react for 24 hours to obtain the photocatalytic material.

[0067] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com