Methane complete combustion catalyst and preparation method thereof

A complete combustion, methane combustion technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low methane combustion activity, increase specific surface area, specific surface area Small and other problems, to achieve the effect of low preparation cost, simple process and high degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Under the conditions of stirring and room temperature, dissolve lanthanum nitrate, nickel nitrate, and citric acid in water or absolute ethanol solution at a molar ratio of 1:1:2, and stir for 6 hours to form a complex sol. The resulting sol Heat to 80°C to evaporate for 4 hours to make it into a gel, dry it under vacuum at 60°C for 10 hours, and grind to obtain a powder sample. Then heat the powder to 350 ° C and burn it completely black, and then bake it at a high temperature of 700 ° C for 3 hours to obtain LaNiO 3 crystals. Finally LaNiO 3 Soak in 0.5mol / L acetic acid for 30min, separate, wash with water, and dry at 70°C for 12 hours to obtain NiO / LaNiO 3 The methane burns completely over the catalyst.

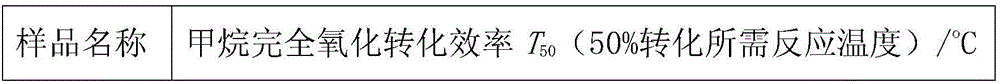

[0019] This catalyst is used in methane complete oxidation experiment, and the result shows that 0.1g catalyst completely oxidizes T to 6% methane 50 (reaction temperature required for 50% conversion) is about 484°C, see Table 1.

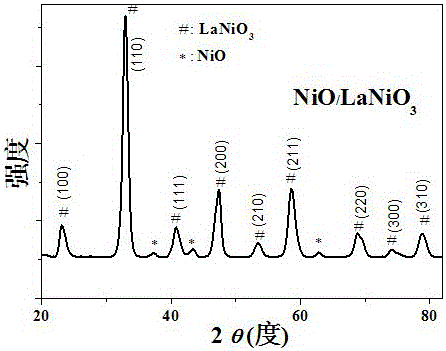

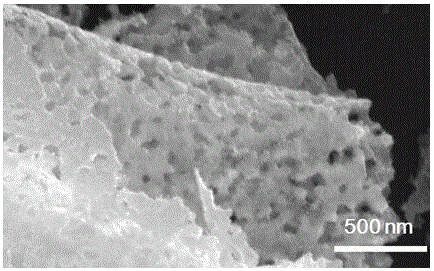

[0020] figure 1 The NiO / LaNi...

Embodiment 2

[0022] Under the conditions of stirring and room temperature, lanthanum nitrate, nickel nitrate, and citric acid were dissolved in water or absolute ethanol solution at a molar ratio of 1:1:5, and stirred for 6 hours to form a complex sol. The sol was heated to 80° C. to evaporate for 4 hours to make it into a gel, dried under vacuum at 80° C. for 2 hours, and ground to obtain a powder sample. Then heat the powder to 350 ° C and burn it completely black, and then bake it at a high temperature of 650 ° C for 5 hours to obtain LaNiO 3 crystals. Finally LaNiO 3 Soak in 0.1mol / L acetic acid for 120min, separate, wash with water, and dry at 70°C for 12 hours to obtain NiO / LaNiO 3 The methane burns completely over the catalyst. It is confirmed as LaNiO by XRD spectrum 3 (main phase) and NiO two-phase coexistence structure, NiO in LaNiO 3 Good surface dispersion.

[0023]This catalyst is used in methane complete oxidation experiment, and the result shows that 0.1g catalyst comp...

Embodiment 3

[0025] Under the conditions of stirring and room temperature, lanthanum nitrate, nickel nitrate, and citric acid were dissolved in water or absolute ethanol solution at a molar ratio of 1:1:5, and stirred for 6 hours to form a complex sol. The sol was heated to 100° C. to evaporate for 2 hours to make it into a gel, dried under vacuum at 70° C. for 5 hours, and ground to obtain a powder sample. Then heat the powder to 500 ° C and burn it completely black, and then bake it at a high temperature of 750 ° C for 2 hours to obtain LaNiO 3 crystals. Finally LaNiO 3 Soak in 1mol / L acetic acid for 10min, separate, wash with water, and dry at 60°C for 12 hours to obtain NiO / LaNiO 3 The methane burns completely over the catalyst. It is confirmed as LaNiO by XRD spectrum 3 (main phase) and NiO two-phase coexistence structure, NiO in LaNiO 3 Good surface dispersion.

[0026] This catalyst is used in methane complete oxidation experiment, and the result shows that 0.1g catalyst compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com