Elastic wood floor manufacturing method

A wood floor, elastic technology, applied in the field of wood floor manufacturing, can solve problems such as easy slip and fall injury, and achieve the effect of increasing flexibility, increasing foot comfort, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the elastic wooden floor disclosed in this embodiment comprises the following steps:

[0028] (1) Carry out coarse sand and twice fine sand treatment to the wooden floor slab;

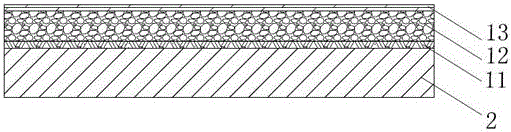

[0029] (2) Coating sequentially on the treated slab surface: (a) adhesion layer; (b) elastic layer; (c) stain-resistant surface layer.

[0030] The treatment process for the adhesion layer is as follows:

[0031] Step 0101: Coating a water-based primer on the surface of the finely sanded slab and drying it by infrared rays. The water-based primer adopts the WB-23 type paint sold by Shanghai Xiechengchang Chemical Co., Ltd., and the coating amount is controlled at 10g / m 2 , followed by infrared drying at 65°C. In the infrared drying, the floor passes through a 10-meter-long drying tunnel at a speed of 16m / min. The degree of drying depends on the dryness to the touch.

[0032] Step 0102 Apply the oil sealing primer and perform UV drying. The oil sealing primer adopts ...

Embodiment 2

[0046] The preparation method of the elastic wooden floor disclosed in this embodiment comprises the following steps:

[0047] (1) Carry out coarse sand and twice fine sand treatment to the wooden floor slab;

[0048] (2) Coating sequentially on the treated slab surface: (a) adhesion layer; (b) elastic layer; (c) stain-resistant surface layer.

[0049] The treatment process for the adhesion layer is as follows:

[0050] Step 0201: Apply a water-based primer on the surface of the finely sanded slab and dry it with infrared rays. The water-based primer adopts the WB-23 type paint sold by Shanghai Xiechengchang Chemical Co., Ltd., and the coating amount is controlled at 13g / m 2 , followed by infrared drying at 70°C. In the infrared drying, the floor passes through a drying tunnel with a length of 10 meters at a speed of 16m / min. The degree of drying depends on the dryness of the hand.

[0051] Step 0202 Apply the oil sealing primer and perform UV drying. The oil sealing prime...

Embodiment 3

[0065] The preparation method of the elastic wooden floor disclosed in this embodiment comprises the following steps:

[0066] (1) Carry out coarse sand and twice fine sand treatment to the wooden floor slab;

[0067] (2) Coating sequentially on the treated slab surface: (a) adhesion layer; (b) elastic layer; (c) stain-resistant surface layer.

[0068] The treatment process for the adhesion layer is as follows:

[0069] Step 0301: Coating a water-based primer on the surface of the finely sanded slab and drying it by infrared rays. The water-based primer adopts the WB-23 type paint sold by Shanghai Xiechengchang Chemical Co., Ltd., and the coating amount is controlled at 15g / m 2 , followed by infrared drying at 70°C. In the infrared drying, the floor passes through a drying tunnel with a length of 10 meters at a speed of 18m / min. The degree of drying is based on the dryness to the touch.

[0070] Step 0302 Apply the oil sealing primer and perform UV drying. The oil sealing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap