Ceramic silicone rubber and preparation method thereof

A technology for ceramicizing silicone rubber and silicone rubber, applied in the field of rubber materials, can solve the problems of unable to maintain the integrity of wires and cables, turning into ashes, secondary disasters, etc., to improve the magnetization shell performance, optimize the overall performance, and maintain integrity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

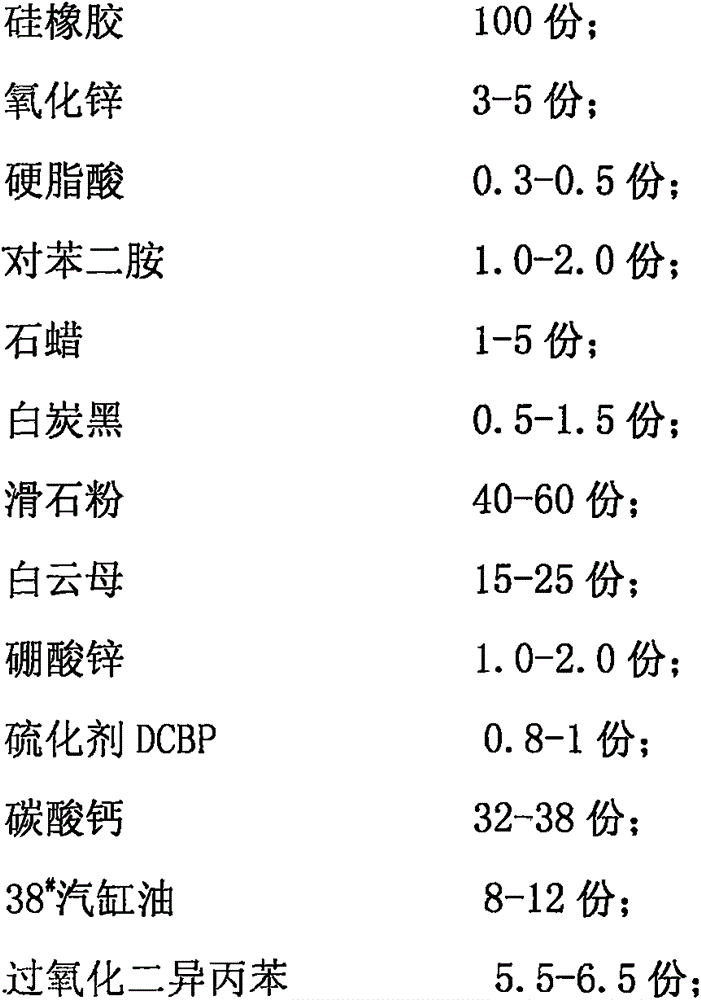

Method used

Image

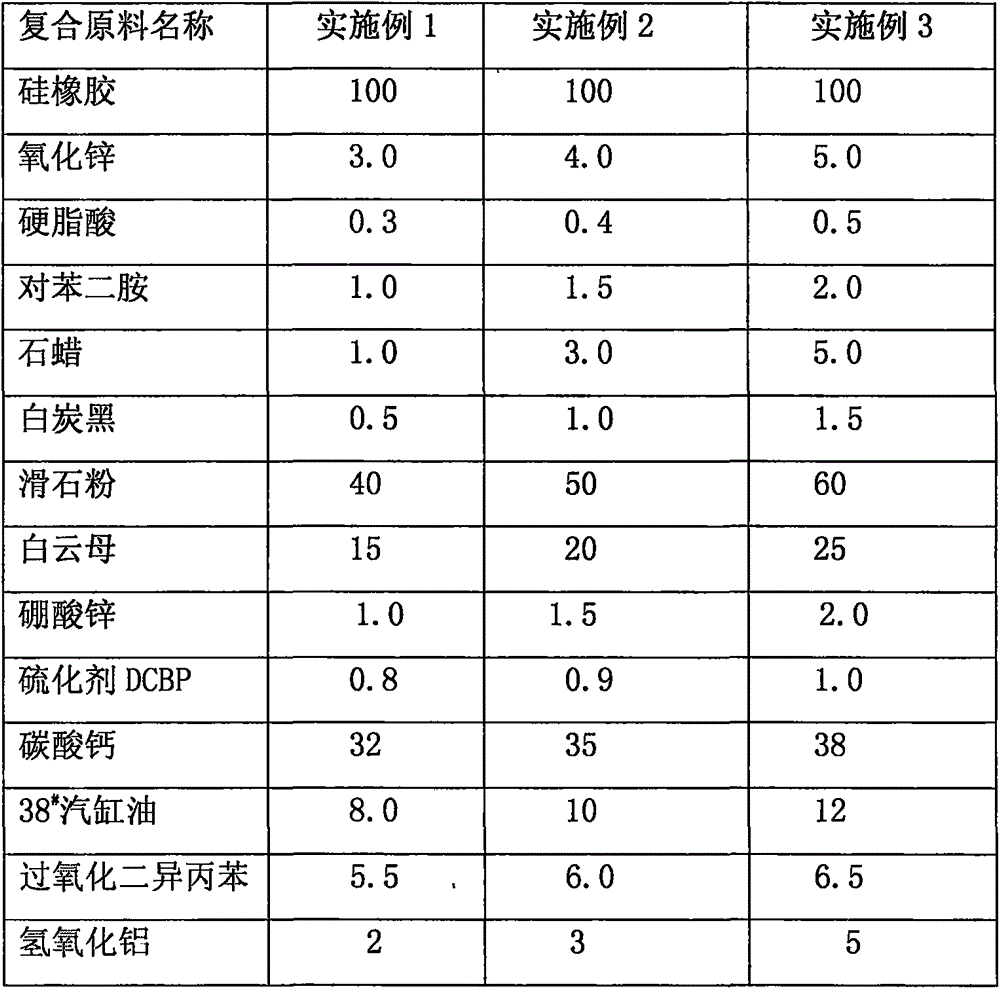

Examples

Embodiment 1

[0016] 100 parts by weight of silicone rubber; 3.0 parts by weight of zinc oxide; 0.3 parts by weight of stearic acid, 1.0 parts by weight of p-phenylenediamine; 1.0 parts by weight of paraffin wax; 2 parts by weight of aluminum hydroxide; 2 parts by weight of magnesium hydroxide; 0.5 parts by weight of white carbon black 40 parts by weight of talcum powder; 15 parts by weight of muscovite; 1.0 parts by weight of zinc borate; 0.8 parts by weight of vulcanizing agent DCBP (bis-(2,4-dichlorobenzoyl peroxide)); 32 parts by weight of calcium carbonate ;38 # 8.0 parts by weight of cylinder oil; 5.5 parts by weight of dicumyl peroxide. First, mix the silicone rubber in the rubber mixer for 1.5 minutes, then put the mixture of zinc oxide, stearic acid, anti-aging agent, paraffin, magnesium hydroxide and aluminum hydroxide into the rubber mixer for 2 minutes, and then put the white The mixture of carbon black, talcum powder, muscovite, zinc borate, vulcanizing agent DCBP was put into...

Embodiment 2

[0018] 100 parts by weight of silicone rubber; 4.0 parts by weight of zinc oxide; 0.4 parts by weight of stearic acid, 1.5 parts by weight of p-phenylenediamine; 3.0 parts by weight of paraffin; 3 parts by weight of aluminum hydroxide; 3 parts by weight of magnesium hydroxide; 1.0 parts by weight of white carbon black Parts by weight; 50 parts by weight of talcum powder; 20 parts by weight of muscovite; 1.5 parts by weight of zinc borate; 0.9 parts by weight of vulcanizing agent DCBP; 35 parts by weight of calcium carbonate; # 10 parts by weight of cylinder oil; 6.0 parts by weight of dicumyl peroxide, at first silicone rubber was mixed in rubber mixer for 1.5 minutes, then zinc oxide, stearic acid, anti-aging agent, paraffin, magnesium hydroxide and aluminum hydroxide were mixed Put the mixture of white carbon black, talcum powder, muscovite, zinc borate, vulcanizing agent DCBP into the rubber mixer and mix for 2.5 minutes, and then add calcium carbonate, 38 # The mixture of...

Embodiment 3

[0020] 100 parts by weight of silicone rubber; 5.0 parts by weight of zinc oxide; 0.5 parts by weight of stearic acid, 2.0 parts by weight of p-phenylenediamine; 5.0 parts by weight of paraffin; 5 parts by weight of aluminum hydroxide; 5 parts by weight of magnesium hydroxide; 1.5 parts by weight of white carbon black Parts by weight; 60 parts by weight of talcum powder; 25 parts by weight of muscovite; 2.0 parts by weight of zinc borate; 1.0 parts by weight of vulcanizing agent DCBP; 38 parts by weight of calcium carbonate; # 12 parts by weight of cylinder oil; 6.5 parts by weight of dicumyl peroxide, first silicone rubber was mixed in a rubber mixer for 1.5 minutes, then zinc oxide, stearic acid, anti-aging agent, paraffin, magnesium hydroxide and aluminum hydroxide were mixed Put the mixture of white carbon black, talcum powder, muscovite, zinc borate, vulcanizing agent DCBP into the rubber mixer and mix for 2.5 minutes, and finally calcium carbonate, 38 # The mixture of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com