Phenolic resin adhesive containing demethylated lignin and preparation method of phenolic resin adhesive

A phenolic resin glue and demethylation technology, which is applied in the field of materials, can solve the problems of high free phenol content and high cost, and achieve the effects of reducing free phenol content, improving reactivity, and efficiently utilizing the pressure of petroleum resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

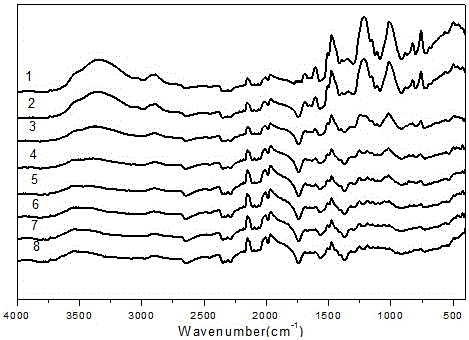

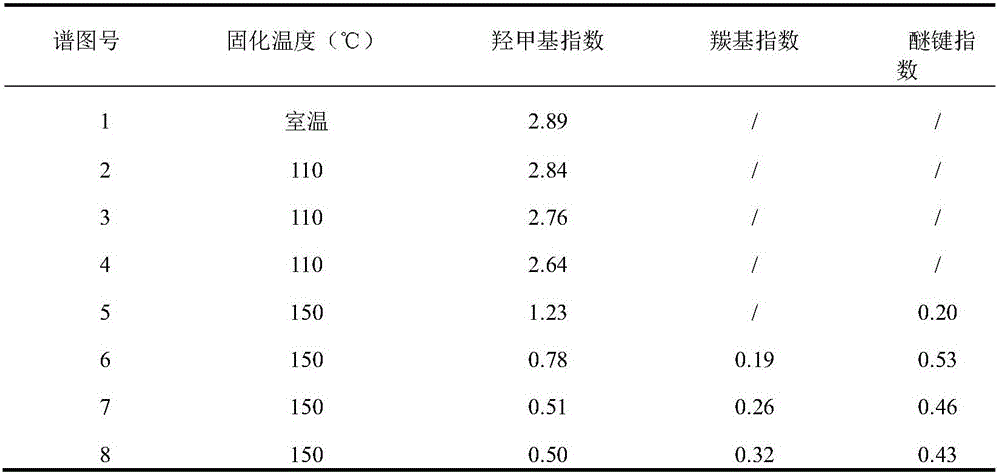

Image

Examples

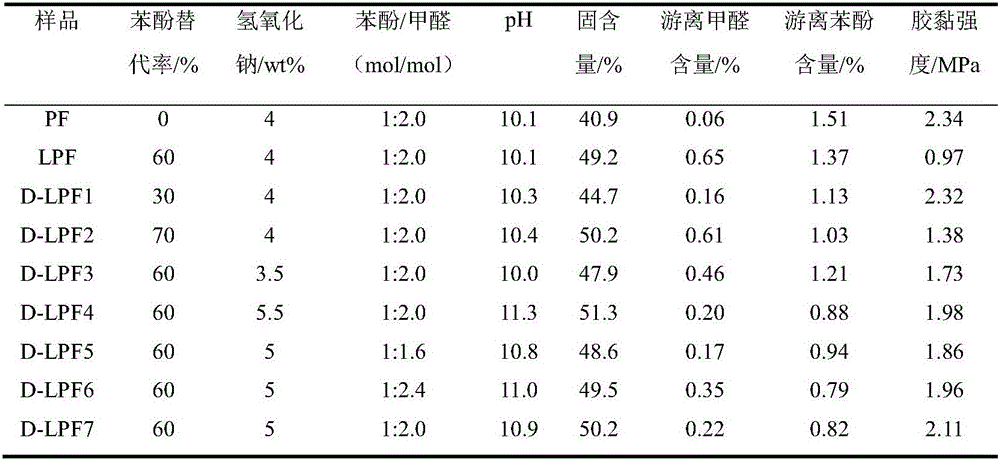

Embodiment 1

[0017] Using in-situ generated Lewis acid as a modifier, wheatgrass alkali lignin:N,N-dimethylformamide is 1:19.0(w / w), wheatgrass alkali lignin:iodocyclohexane is 1:12( mol / mol). Dissolve wheatgrass alkali lignin in dimethylformamide, stir to disperse the system evenly, slowly add iodocyclohexane dropwise, raise the temperature to 145°C while stirring, and react under nitrogen protection for 7h. The demethylated lignin is obtained after rotary evaporation, centrifugation, washing and drying. The substitution rate of above-mentioned demethylated lignin to phenol is 30%, the consumption of sodium hydroxide is 4% of total solution quality, the mol ratio of phenol and formaldehyde is 1:2 (mol / mol), the ratio of phenol and water The molar ratio is 0.15:1 (mol / mol), and the molar ratio of phenol to demethylated lignin is 97.2:1 (mol / mol). Add phenol, sodium hydroxide, water and formaldehyde solution to a 100mL three-necked flask , heated to 60°C, stirred to disperse the system ev...

Embodiment 2

[0019] On the basis of Example 1, the substitution rate of demethylated lignin to phenol is 70%, the consumption of sodium hydroxide is 4% of the total solution quality, and the molar ratio of phenol and formaldehyde is 1:2 (mol / mol), the molar ratio of phenol and water is 0.1:1 (mol / mol), the molar ratio of phenol and demethylated lignin is 17.9:1 (mol / mol), the phenol, sodium hydroxide, water and formaldehyde Add the solution into a 100mL three-necked flask, heat to 60°C, stir to disperse the system evenly, then raise the temperature to 90°C, keep the temperature for 1.5h, then add demethylated lignin, continue to keep the heat for 2h, cool out The material was used to obtain a demethylated lignin-containing phenolic resin adhesive (D-LPF2).

Embodiment 3

[0021] On the basis of Example 1, the substitution rate of demethylated lignin to phenol is 60%, the consumption of sodium hydroxide is 3.5% of the total solution quality, and the molar ratio of phenol to formaldehyde is 1:2 (mol / mol), the molar ratio of phenol and water is 0.15:1 (mol / mol), the molar ratio of phenol and demethylated lignin is 27.8:1 (mol / mol), the phenol, sodium hydroxide, water and formaldehyde Add the solution into a 100mL three-necked flask, heat to 60°C, stir to disperse the system evenly, then raise the temperature to 90°C, keep the temperature for 1.5h, then add demethylated lignin, continue to keep the heat for 2h, cool out The material was used to obtain a demethylated lignin-containing phenolic resin adhesive (D-LPF3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com