Self-heating hot compress material and preparation method thereof

A thermal and spontaneous technology, applied in the field of composite materials, can solve the problems of porous pore size distribution, unapplied self-heating materials, large specific surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Specifically, the preparation method of the self-heating hot compress material provided by the present invention includes:

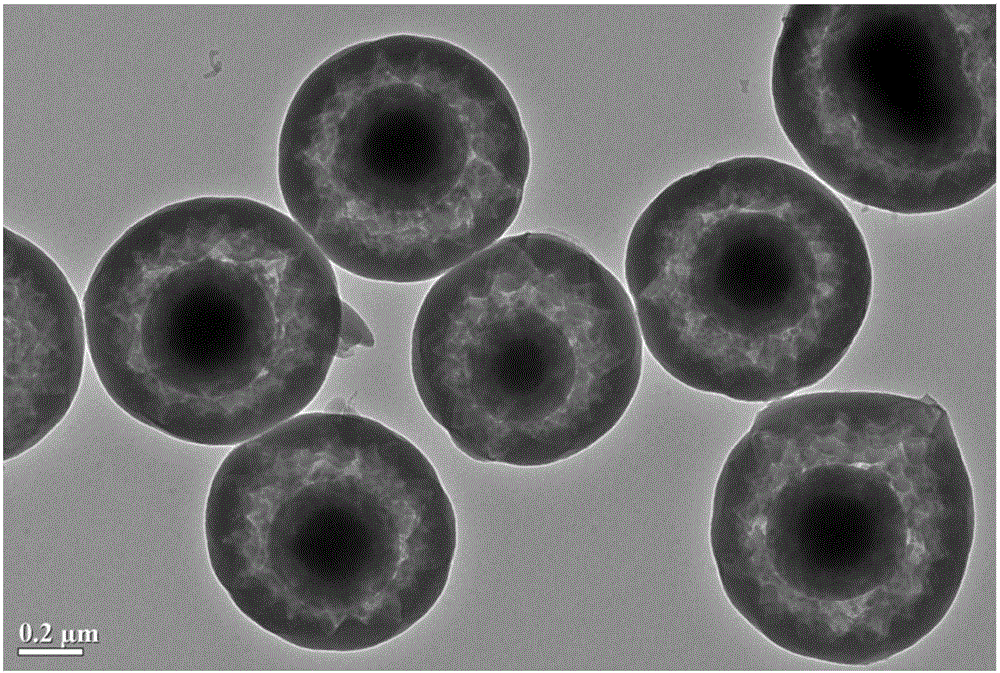

[0025] Step 1, with Fe 3 o 4 PSPF core-shell magnetic composite microspheres are used as seeds, and under the catalysis of ammonia water, the phenolic resin is uniformly coated on Fe 3 o 4 PSPF core-shell magnetic composite microsphere surface;

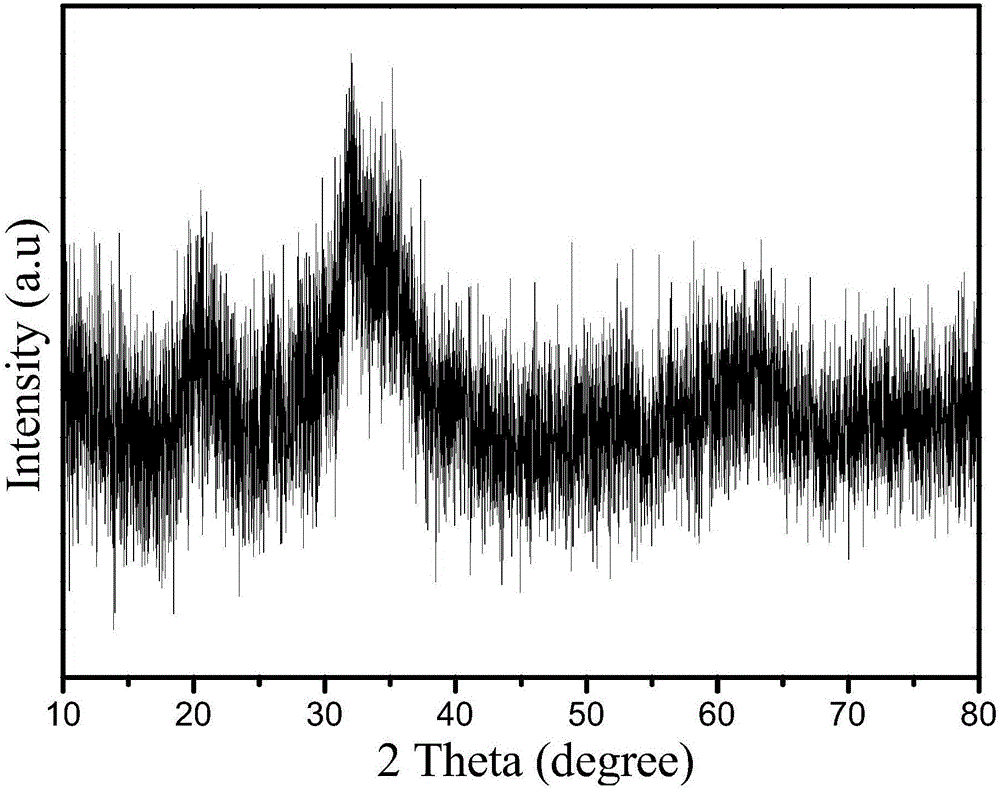

[0026] Step 2, carbonizing the product prepared in step 1 under the protection of nitrogen to obtain hollow porous magnetic nano-carbon spheres;

[0027] Step 3. Mechanically blend the above-mentioned hollow porous magnetic nano-carbon spheres, reduced iron powder, ancient sea essence brine, water, water-absorbing resin, calamus calamus and mugwort to prepare a self-heating hot compress material.

[0028] In the above examples, the ancient sea essence brine refers to the deep ancient sea essence brine in the ancient sea of China (located in Zhangshu, Jiangxi), which is thousands of meters undergroun...

Embodiment 1

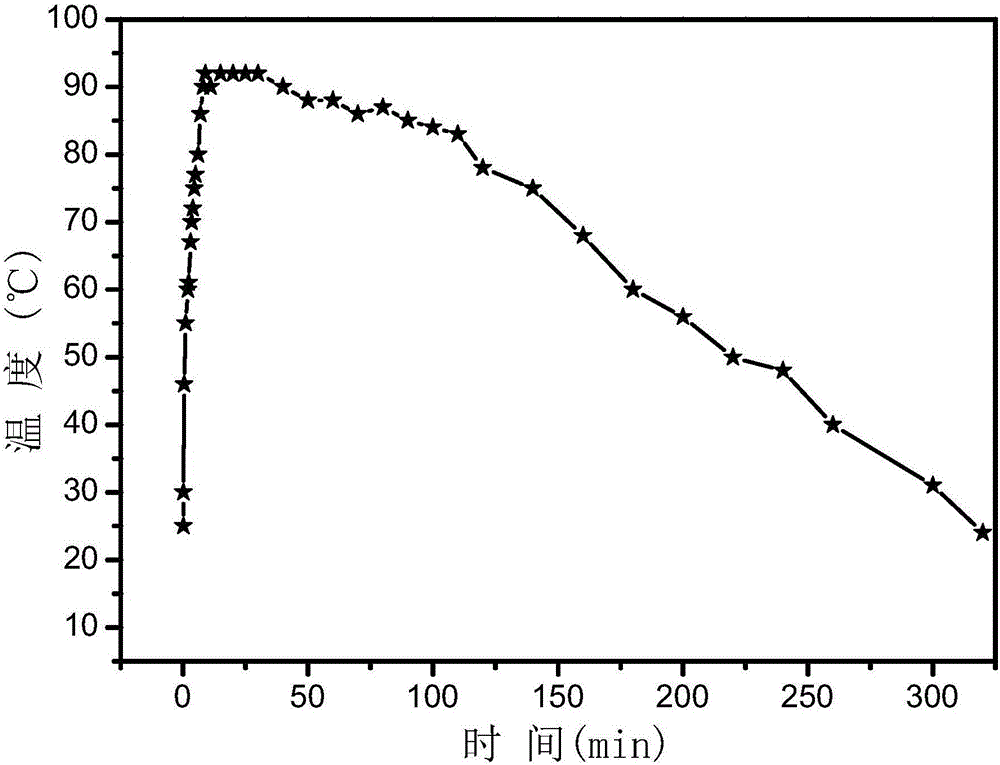

[0054] Example 1. Preparation of a self-heating hot compress material with a heating temperature of 40°C

[0055] (1) Add 10g of Fe 3 o 4 PSPF core-shell magnetic composite microspheres were dispersed in deionized water, 5ml of ammonia water, 1.0ml of formaldehyde and 20mg of phenol were added and transferred to a microwave tube for reaction under microwave radiation at a reaction temperature of 200°C and a reaction time of 1h.

[0056] (2) After the reaction is completed, the product is magnetically separated, washed with deionized water and absolute ethanol, and dried in vacuum.

[0057] (3) The above product was put into a muffle furnace, and carbonized at a high temperature of 800° C. for 6 hours under the protection of nitrogen to obtain hollow porous magnetic nanocarbon spheres.

[0058] (4) Mix 1.0g of hollow porous magnetic nanocarbon spheres, 1.0g of ancient sea essence brine salt and 1.0ml of water, let stand for 10min, then add 0.2g of carboxymethyl cellulose, 0.2...

Embodiment 2

[0059] Example 2. Preparation of a self-heating hot compress material with a heating temperature of 50°C

[0060] (1) Add 10g of Fe 3 o 4 PSPF core-shell magnetic composite microspheres were dispersed in deionized water, 5ml of ammonia water, 5.0ml of formaldehyde and 100mg of phenol were added and transferred to a microwave tube to react under microwave radiation at a reaction temperature of 200°C and a reaction time of 1h.

[0061] (2) After the reaction is completed, the product is magnetically separated, washed with deionized water and absolute ethanol, and dried in vacuum.

[0062] (3) The above product was put into a muffle furnace, and carbonized at a high temperature of 800° C. for 6 hours under the protection of nitrogen to obtain hollow porous magnetic nanocarbon spheres.

[0063] (4) Mix 2.0g of hollow porous magnetic nanocarbon spheres, 3.5g of ancient sea essence brine salt and 2.0ml of water, let stand for 10min, then add 0.2g of carboxymethyl cellulose, 0.5g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com