Method for efficiently purifying biogas slurry in pig farm through composite microalgae

A technology of biogas slurry and microalgae, which is applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of difficult operation, high cost, and environmental pollution of biogas slurry, so as to improve the environment and reduce costs. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

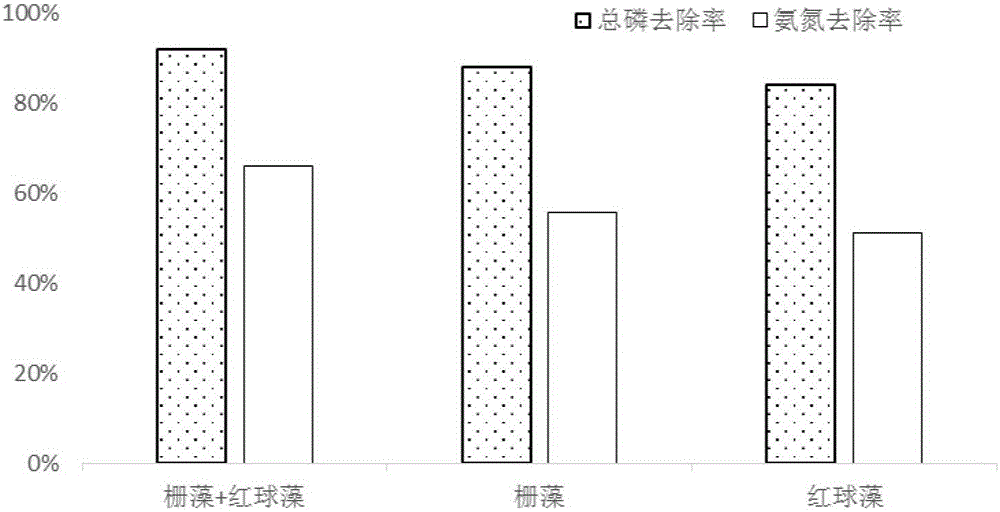

[0020] Example 1: Treatment of pig farm biogas slurry with compound microalgae

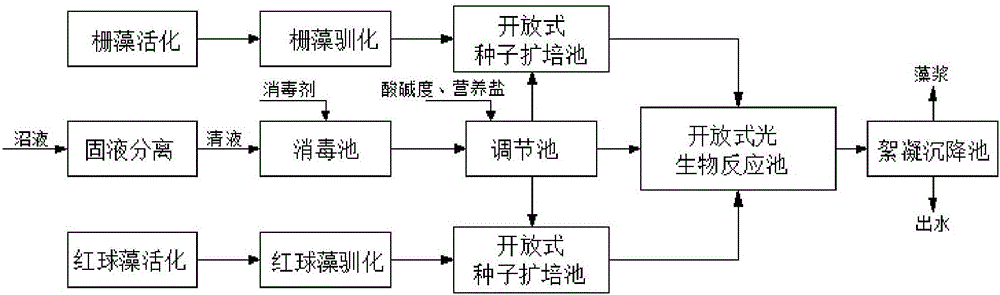

[0021] Such as figure 1 , the present invention utilizes composite microalgae to efficiently purify pig farm biogas slurry method comprising the following steps:

[0022] 1. Biogas slurry pretreatment: The biogas slurry after anaerobic fermentation is separated by a solid-liquid separator and enters the disinfection tank at night, and is disinfected with 10% sodium hypochlorite solution (mass fraction of available chlorine> 10.0) 0.1mL / L. Then enter the adjustment pool for pH and nutrient adjustment, and the water in the adjustment pool is introduced into the seed expansion tank and the open photobiological reaction tank;

[0023] 2. Activation of microalgae: Inoculate Scenedesmus and Haematococcus into 250ml Erlenmeyer flasks filled with 200ml of BG11 medium, shake well, and culture under the conditions of temperature 25°C, light intensity 5000lux, and light-dark ratio 12:12h 5d to obtain the l...

Embodiment 2

[0029] Embodiment 2: Treatment of pig farm biogas slurry by Scenedesmus

[0030] This case is a comparative test of Case 1. Only Scenedesmus was used to treat pig farm biogas slurry, and other treatment steps were the same.

[0031] 1. Biogas slurry pretreatment: The biogas slurry after anaerobic fermentation is separated by a solid-liquid separator and enters the disinfection tank at night, and is disinfected with 10% sodium hypochlorite solution (mass fraction of available chlorine> 10.0) 0.1mL / L. Then enter the adjustment pool for pH and nutrient adjustment, and the water in the adjustment pool is introduced into the seed expansion tank and the open photobiological reaction tank;

[0032] 2. Activation of microalgae: Inoculate Scenedesmus into a 250ml Erlenmeyer flask containing 200ml of BG11 medium, shake well, and culture for 5 days under the conditions of temperature 25°C, light intensity 5000lux, light-dark ratio 12:12h to obtain logarithmic growth Stage microalgae mo...

Embodiment 3

[0038] Embodiment 3: Haematococcus treatment pig farm biogas slurry

[0039] This case is a comparative test of Case 1. Only Haematococcus was used to treat pig farm biogas slurry, and other treatment steps were the same.

[0040] 1. Biogas slurry pretreatment: The biogas slurry after anaerobic fermentation is separated by a solid-liquid separator and enters the disinfection tank at night, and is disinfected with 10% sodium hypochlorite solution (mass fraction of available chlorine> 10.0) 0.1mL / L. Then enter the adjustment pool for pH and nutrient adjustment, and the water in the adjustment pool is introduced into the seed expansion tank and the open photobiological reaction tank;

[0041] 2. Activation of microalgae: Inoculate Haematococcus into a 250ml Erlenmeyer flask containing 200ml of BG11 medium, shake well, and culture for 5 days under the conditions of temperature 25°C, light intensity 5000lux, and light-dark ratio 12:12h to obtain logarithm Growth stage microalgae ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com