High-efficient compounding plant inhibitor as well as preparation method and application thereof

A technology of corrosion inhibitors and plants, which is applied in the field of high-efficiency compound plant corrosion inhibitors and its preparation, can solve the problems of hindering the development and application of corrosion inhibitors, poor water solubility, application restrictions, etc., and achieve obvious synergy, low cost, quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

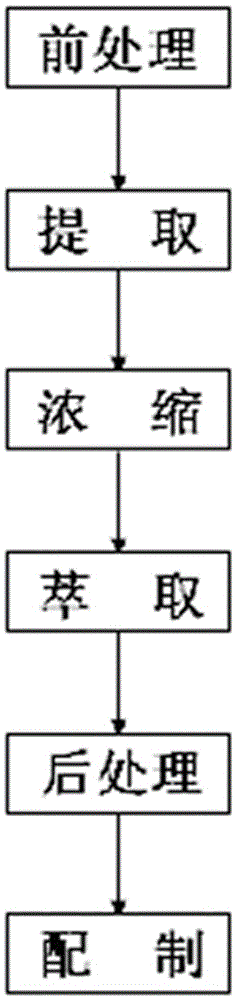

[0019] The preparation method of the high-efficiency compound plant corrosion inhibitor includes raw material preparation and preparation steps, specifically including:

[0020] A. Raw material preparation: prepare plant extracts for subsequent use, prepare natural polymer compounds, auxiliary agents, and pickling liquid for subsequent use;

[0021] B. Preparation: Add plant extracts, natural macromolecular compounds, and auxiliary agents into the pickling solution according to the ratio of raw materials, stir and mix well to obtain the target product.

[0022] 8. The method for preparing a high-efficiency compound plant corrosion inhibitor according to claim 7, characterized in that: the plant extracts are walnut green bark extract and black wattle leaf extract, and the walnut green bark extract is prepared according to Prepared in the following steps:

[0023] A. Pre-treatment: After collecting walnut green skin, remove surface impurities, rinse with water to remove dust, d...

Embodiment 1

[0036] Embodiment 1 - the preparation of walnut green husk extract

[0037]A. Pre-treatment: After collecting walnut green skin, remove surface impurities, rinse with water to remove dust, drain surface moisture, first cut into slices with a knife, air-dried, put in a blast oven, dry at 50°C for 60 hours, take out the natural Pulverized after cooling to room temperature, the walnut green skin powder with a particle size of 300-1000 μm;

[0038] B. Extraction: Soak walnut green skin powder with 10% ethanol solution at 10°C for 4 hours, solid-to-liquid ratio 1:20, then reflux in a water bath at 50°C for 3 hours;

[0039] C. Concentration: Vacuum suction filtration of the ethanol extract obtained by reflux to remove the walnut green husk powder contained therein, and then take it on a rotary evaporator at 40 ° C to concentrate the solution to 1 / 3 volume by rotary evaporation;

[0040] D. Extraction: Add 5 times the volume of petroleum ether to the concentrated ethanol extract, s...

Embodiment 2

[0042] Embodiment 2——Preparation of walnut green husk extract

[0043] A. Pre-treatment: After collecting walnut green skin, remove surface impurities, rinse with water to remove dust, drain surface moisture, first cut into slices with a knife, air-dried and put in a blast oven, dry at 60°C for 48 hours, take out the natural Pulverized after cooling to room temperature, the walnut green skin powder with a particle size of 300-1000 μm;

[0044] B. Extraction: Soak the walnut green peel powder with a concentration of 45% ethanol solution at 20°C for 2.5h, the solid-to-liquid ratio is 1:25, and then reflux in a water bath at 65°C for 3.5h;

[0045] C. Concentration: Vacuum suction filtration of the ethanol extract obtained by reflux to remove the walnut green husk powder contained therein, and then take it on a rotary evaporator at 40 ° C to concentrate the solution to 1 / 2 volume by rotary evaporation;

[0046] D. Extraction: Add 3.5 times the volume of petroleum ether to the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com