Sun-screen and skin-whitening fabric

A fabric, whitening technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

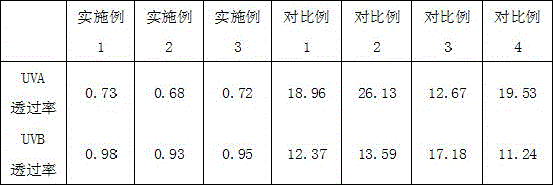

Examples

Embodiment 1

[0022] A kind of sun-proof and whitening fabric, the fabric is firstly made by blending the following raw materials in parts by weight: 60 parts of bamboo fiber, 50 parts of long-staple cotton fiber, 20 parts of pearl fiber, 25 parts of flax fiber, 15 parts of aloe fiber, and 20 parts of mica fiber , 15 parts of milk protein fiber, and then processed through antibacterial sunscreen finishing liquid; said antibacterial sunscreen finishing liquid contains 8 parts of chitosan, 6 parts of tea polyphenols, 2-hydroxyl-4-methoxybenzophenone 2 1 part, 1 part of phenyl phthalate, 1.5 parts of sodium tripolyphosphate, 6 parts of tetradecyltrimethylammonium chloride, 8 parts of polyethylene glycol, 5 parts of polyhexamethylene biguanide, 10 parts of nano-titanium dioxide Parts, 6 parts of N-dodecyl glucosyl lauramide, 5 parts of water-based polyurethane;

[0023] The preparation method comprises the following steps:

[0024] (1) Bamboo fiber, long-staple cotton fiber, pearl fiber, flax ...

Embodiment 2

[0028]A kind of sun-proof and whitening fabric, the fabric is firstly made by blending the following raw materials in parts by weight: 50 parts of bamboo fiber, 60 parts of long-staple cotton fiber, 25 parts of pearl fiber, 20 parts of flax fiber, 16 parts of aloe fiber, and 20 parts of mica fiber , 10 parts of milk protein fiber, and then processed through antibacterial sunscreen finishing liquid; said antibacterial sunscreen finishing liquid contains 5 parts of chitosan, 10 parts of tea polyphenols, 2-hydroxyl-4-methoxybenzophenone 2 1 part, 1 part of phenyl phthalate, 2 parts of sodium tripolyphosphate, 8 parts of tetradecyltrimethylammonium chloride, 5 parts of polyethylene glycol, 8 parts of polyhexamethylene biguanide, 12 parts of nano-titanium dioxide Parts, 6 parts of N-dodecyl glucosyl lauramide, 8 parts of water-based polyurethane;

[0029] The preparation method comprises the following steps:

[0030] (1) Bamboo fiber, long-staple cotton fiber, pearl fiber, flax fi...

Embodiment 3

[0034] A kind of sun-proof and whitening fabric, the fabric is first blended with the following raw materials in parts by weight: 45 parts of bamboo fiber, 65 parts of long-staple cotton fiber, 15 parts of pearl fiber, 25 parts of flax fiber, 12 parts of aloe fiber, and 18 parts of mica fiber , 20 parts of milk protein fiber, and then processed through antibacterial sunscreen finishing solution; said antibacterial sunscreen finishing solution contains 10 parts of chitosan, 5 parts of tea polyphenols, 2.5 parts of 2-hydroxy-4-methoxybenzophenone 1.5 parts, 1.5 parts of phenyl o-hydroxybenzoate, 1.5 parts of sodium tripolyphosphate, 6 parts of tetradecyltrimethylammonium chloride, 7 parts of polyethylene glycol, 10 parts of polyhexamethylene biguanide, 15 parts of nano-titanium dioxide Parts, 8 parts of N-dodecyl glucosyl lauramide, 6 parts of water-based polyurethane;

[0035] The preparation method comprises the following steps:

[0036] (1) Bamboo fiber, long-staple cotton f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com