A kind of assay method of trace silicon in tricobalt tetroxide

A technology of cobalt tetroxide and determination method, which is applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of high analysis results of low content silicon, complicated spectrophotometric operation process, harsh dissolution conditions, etc., and achieve stable and reliable analysis results. , Speed up sample dissolution, and measure the effect of fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

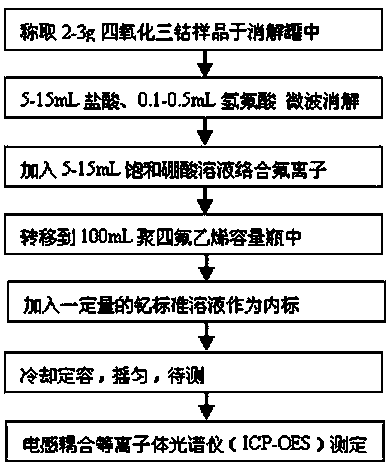

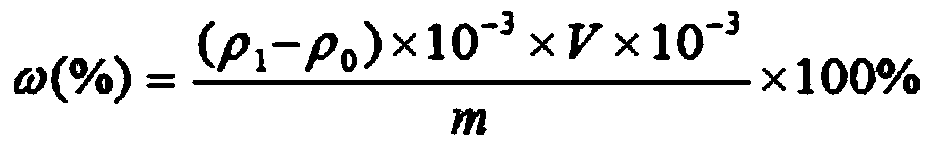

Method used

Image

Examples

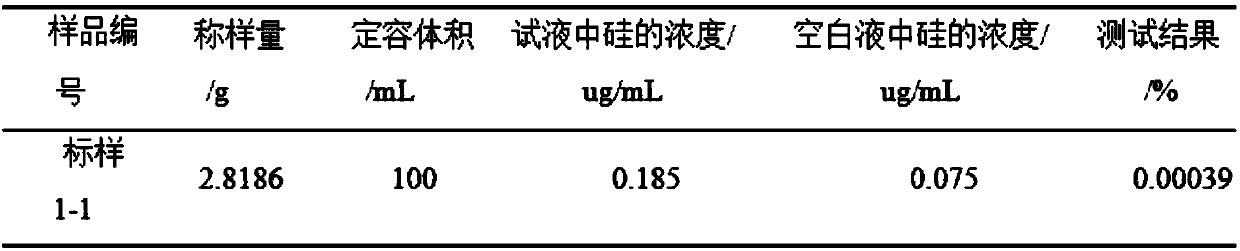

Embodiment 1

[0065] Determination of silicon in standard samples of cobalt tetroxide series: standard sample 1-1 (Si%, 0.00040)

[0066] 1. Instruments and equipment used in the test:

[0067] Inductively coupled plasma optical emission spectrometer Optima 7000DV from American PE company

[0068] Microwave digestion instrument Multiwave PRO from Anton Paar, Austria

[0069] Ultrapure water machine Merck Millipore Milli-Q Reference 15

[0070] Electronic analytical balance Swiss Mettler-Toledo company XS205DU (weighing range 0.1mg ~ 220g)

[0071] 2. Reagents used in the experiment

[0072] Ultra-pure water

[0073] 36%-38% concentrated hydrochloric acid (excellent grade)

[0074] 40% hydrofluoric acid (analytical pure)

[0075] Boric acid (excellent grade)

[0076] Diyttrium trioxide (Y2O3): purity ≥99.999%

[0077] Silica, high purity 5N

[0078] Silicon standard storage solution: burn the standard silicon dioxide (not less than 99.99wt%) at 1000°C for 30min, cool and dry. Weigh...

Embodiment 2

[0106] Determination of silicon in standard samples of cobalt tetroxide series: standard sample 2-1 (Si%, 0.0010)

[0107] Weigh 2.7348g of cobalt tetroxide standard sample 2-1 and place it in a polytetrafluoroethylene digestion tank, then add 5-15mL36% hydrochloric acid and 0.1-0.5mL40% hydrofluoric acid in sequence, assemble the digestion tank, and prepare a blank sample at the same time, Place the microwave digestion jar in the microwave digestion instrument.

[0108] Turn on the microwave digestion instrument, set the program as follows: power 1400W, heating program for 5-20 minutes, after heating to 170-200°C, keep the temperature for 10-20 minutes, pressure 10-50bar, and cool for 10-20 minutes.

[0109] After the digestion program is finished, turn on the microwave digestion instrument and take out the digestion tank when the temperature display reaches below 70°C.

[0110] Add 5-15mL saturated boric acid solution, react at about 30-50°C for 10-30min to complex excess f...

Embodiment 3

[0122] Determination of silicon in standard samples of cobalt tetroxide series: standard sample 3-1 (Si%, 0.0018)

[0123] Weigh 2.7348g of cobalt tetroxide standard sample 3-1 and place it in a polytetrafluoroethylene digestion tank, then add 5-15mL of 36% hydrochloric acid and 0.1-0.5mL of 40% hydrofluoric acid in sequence, assemble the digestion tank, and prepare a blank sample at the same time, Place the microwave digestion jar in the microwave digestion instrument.

[0124] Turn on the microwave digestion instrument, set the program as follows: power 1400W, heating program for 5-20 minutes, after heating to 170-200°C, keep the temperature for 10-20 minutes, pressure 10-50bar, and cool for 10-20 minutes.

[0125] After the digestion program is finished, turn on the microwave digestion instrument and take out the digestion tank when the temperature display reaches below 70°C.

[0126] Add 5-15mL saturated boric acid solution, react at about 30-50°C for 10-30min to complex ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com