Method for embedding micro-ring resonator into D-shaped optical fiber

A technology of micro-ring resonator and optical fiber, which is applied in the field of optoelectronics, can solve problems such as inability to control, and achieve the effect of flat bandwidth and increased integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

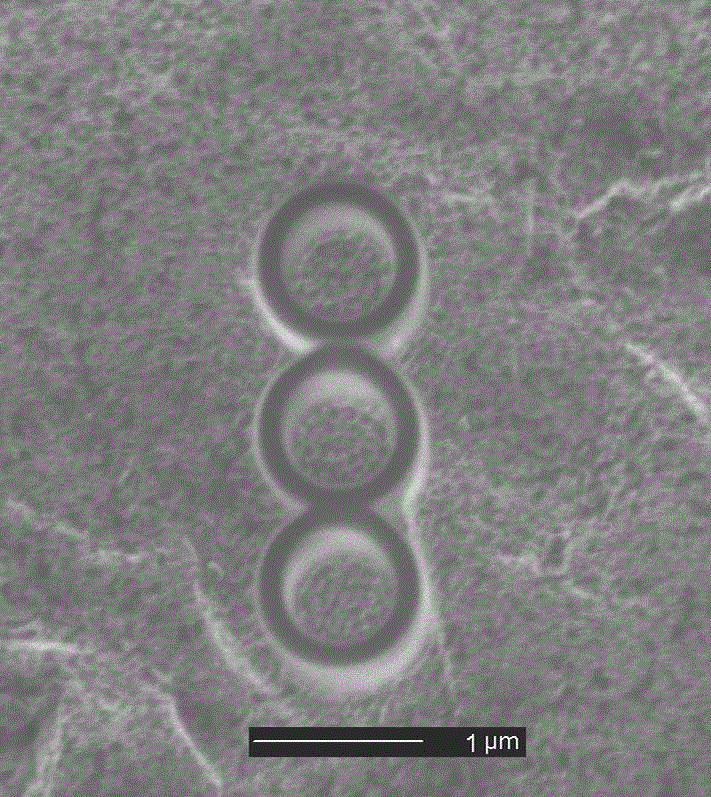

Embodiment 1

[0031] A method for embedding a microring resonator in a D-shaped optical fiber, comprising the steps of:

[0032] (1) Use silica gel to fix the curved part of the D-shaped fiber in a V-shaped groove. The V-shaped groove is 70 microns deep and 127 microns at the widest point. Partially coated with photoresist AZ-1350 and dried;

[0033] (2) Install the dried D-shaped optical fiber and the mask plate on the photolithography machine. The mask plate has slits with a single-peak pattern, and the peak width of the single-peak pattern is 3-10 microns. The peak height is 30 microns, the direction of the peak is along the fiber core direction of the optical fiber, the symmetry axis of the single peak coincides with the midline of the D-shaped optical fiber plane part, and then, the plane part of the D-shaped optical fiber is exposed by a mask plate, The purpose of exposure is to make the photoresist in the photosensitive area of the D-shaped optical fiber plane part through the sli...

Embodiment 2

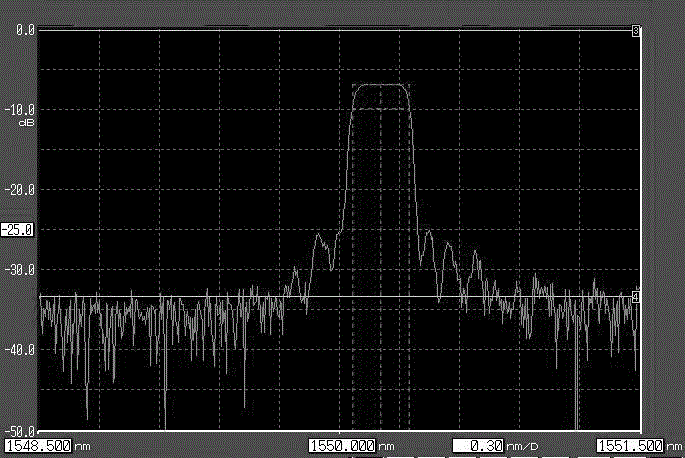

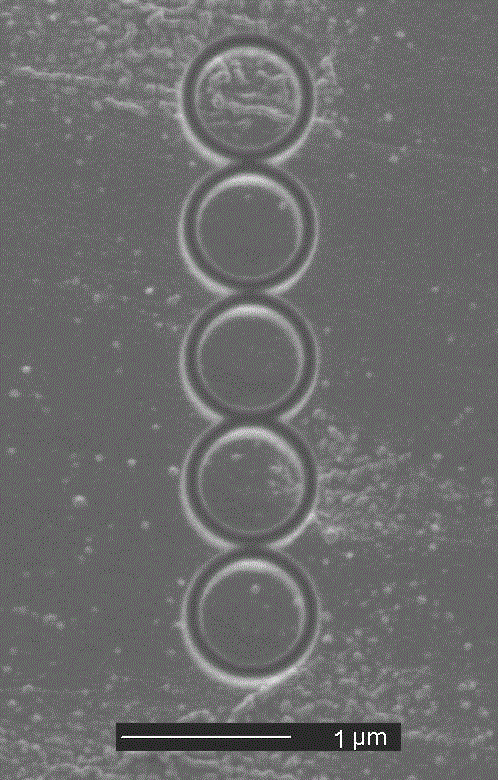

[0038] Steps refer to Example 1. The difference from Example 1 is that step (4) uses focused ion etching to process five cascaded microring resonators. The etched microring resonator structure is as follows image 3 shown. Figure 4 is the transmission spectrum figure of the structure of embodiment 2, by Figure 4 It can be seen that there is an obvious resonance effect at the wavelength of 1549.80-1550.10 nanometers (nm), not only has the characteristics of embodiment 1, but also the spectral line resonance peaks of the 5 resonant rings are sharper, this effect can be used in optical fiber narrowband filters Get valuable applications on it. It can be seen from the calculation that the Q value (quality factor) of the five cascaded resonant microcavities is 3.9×10 5. It shows that with the increase of cascaded resonant microrings, a higher quality factor can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com