Three-dimensional carbon-based pressure sensor making method

A pressure sensor, carbon-based technology, used in sensors, medical science, diagnostic recording/measurement, etc., can solve the problems of high process requirements, large environmental pollution, poor portability, etc., and achieve good biocompatibility, high sensitivity, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

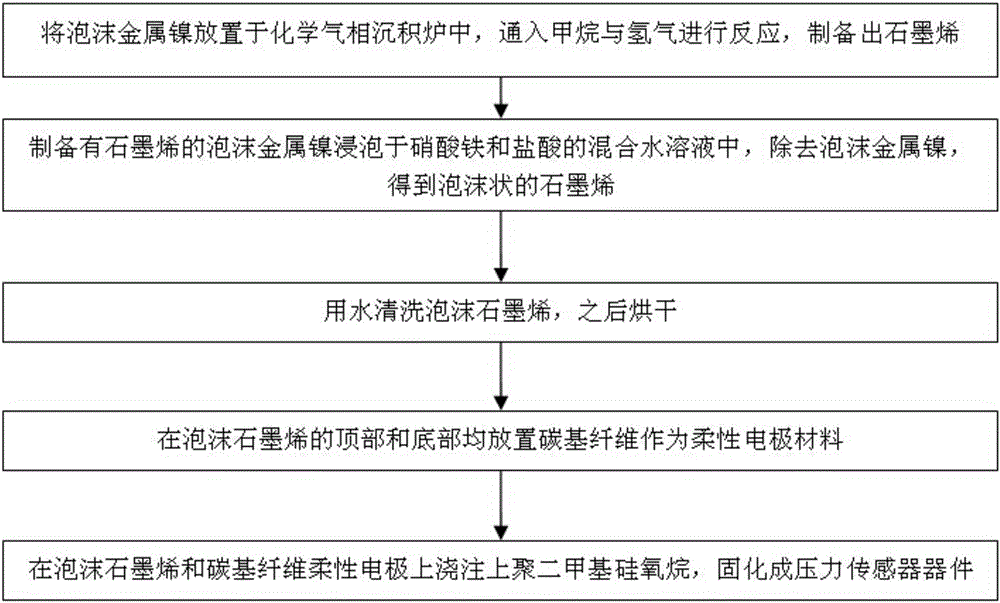

[0027] The schematic flow chart of the present invention is as figure 1 As shown, the specific steps of the preparation method of the three-dimensional carbon-based pressure sensor include:

[0028] Step 1, placing the metal nickel foam in a chemical vapor deposition furnace, feeding methane and hydrogen to react to prepare graphene;

[0029] Step 2, the metal nickel foam prepared with graphene obtained in step 1 is soaked in the mixed aqueous solution of ferric nitrate and hydrochloric acid, and the nickel foam is removed to obtain foamy graphene;

[0030] Step 3, washing the graphene foam with water, and then drying;

[0031] Step 4, placing carbon-based fibers on the top and bottom of the foamed graphene as a flexible electrode material;

[0032] Step 5: Pouring polydimethylsiloxane on the foamed graphene and the carbon-based fiber flexible electrode, and curing it into a pressure sensor device.

[0033] The prepared pressure sensor was subjected to the extrusion-recover...

Embodiment example 1

[0038] Implementation Case 1: Testing of Physiological Signals

[0039] Attach the prepared pressure sensor to the wrist pulse, connect it to the digital source meter,

[0040] (i) Monitor the pulse rate when awake and the pulse rate during sleep.

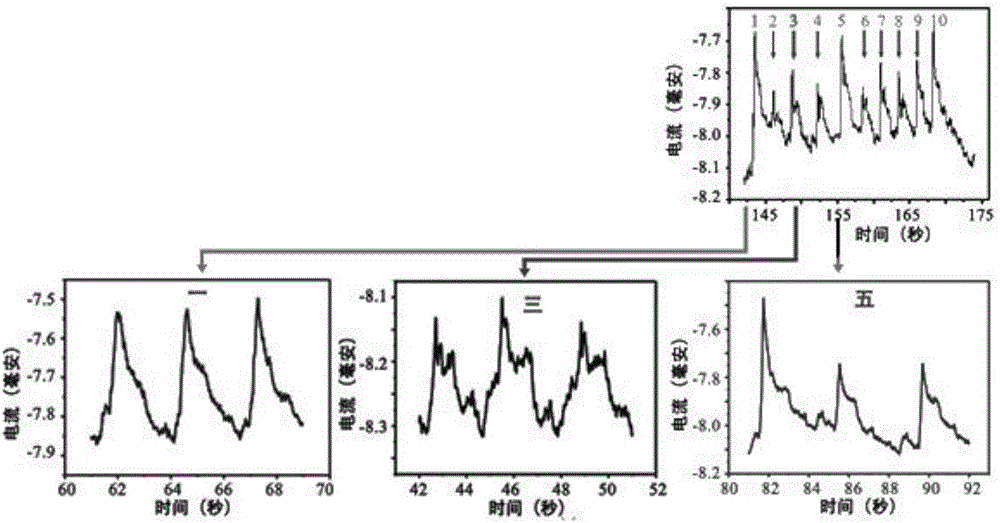

[0041] (ii) Attach the pressure sensor near the throat, read it from 1 to 10, and the digital source meter records the curve of the current flowing through the device with time, such as figure 2 shown. Pick out the three numbers 1, 3, and 5, read each number three times, compare the original curves from 1 to 10, and find that their current waveforms are consistent. This shows that our pressure sensor can detect very sensitively the weak vibration pressure generated when speaking.

Embodiment example 2

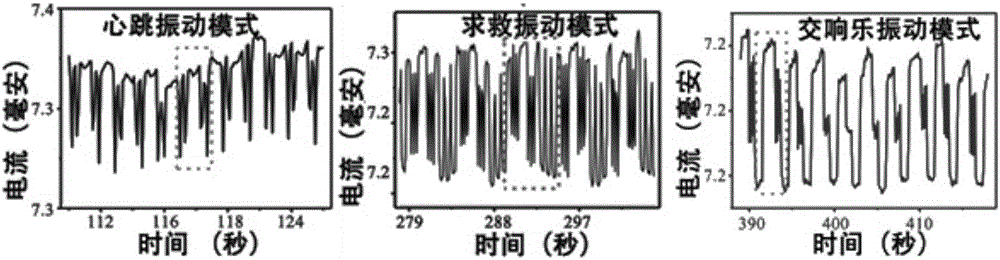

[0043] Put the pressure sensor on the iPhone6, and set the iPhone6 to vibration mode. When dialing the mobile phone, the pressure sensor detects the vibration waveform of the mobile phone in different vibration modes, and obtains a stable current-time diagram of different waveforms, such as image 3 shown.

[0044]The preparation method of the present invention is simple and easy, the raw materials are cheap, and the preparation process is simple. Firstly, a pressure sensor is prepared by preparing a novel carbon-based material foamed graphene. The preparation method of this material is mature, cheap and easy to operate. Afterwards, the prepared foamed graphene is combined with the flexible carbon fiber electrode, and then polydimethylsiloxane PDMS is poured on it, and the pressure sensor device is prepared by curing.

[0045] As can be seen from the above specific examples, the present invention is sensitive to low pressure:

[0046] 1. The pressure sensor of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com