Composite device for aftertreatment of ship low-speed diesel engine end gas

A tail gas post-treatment and composite device technology, which is applied in the field of diesel engine systems, can solve problems such as reactor fouling and wastewater treatment, and achieve energy saving and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

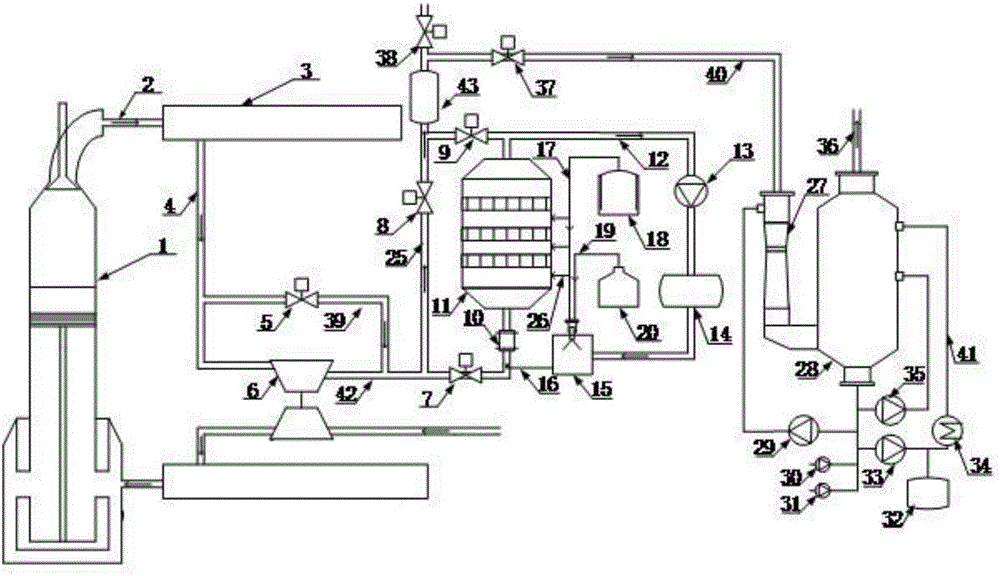

[0016] Hereinafter, the present invention will be described in more detail with examples in conjunction with the drawings:

[0017] Combine figure 1 , The composite device for post-treatment of exhaust gas of low-speed marine diesel engine of the present invention mainly includes: SCR denitration system and wet scrubbing system. The denitration system mainly includes: SCR reactor 11, mixer 10, evaporator 15, compressed air source 18, urea supply unit 20, blower 13, burner 14, conversion valve and connecting pipeline; washing system includes: washing tower 28, Venturi scrubber 27, heat exchanger 34, wastewater treatment unit 32, supply pumps for sea water, lye and circulating liquid, and connecting pipes and sensors. It is characterized in that the turbine bypass pipeline 39 is connected to the outlet pipeline of the turbine 6 through the bypass valve 5, and the turbine 6 is connected to the SCR reactor 11 through the outlet pipeline 42 through the reactor sealing valve 7 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com