Hydrophobic modification method of silica gel under effect of ultrasonic waves

An ultrasonic and hydrophobic technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of improving hydrophobicity and the ability to adsorb organic substances, wide source of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

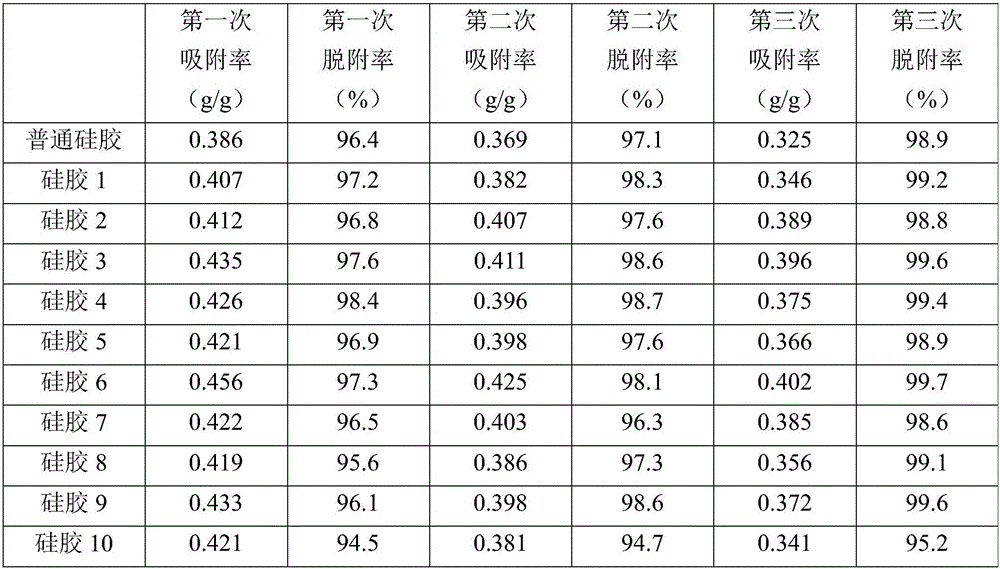

Examples

Embodiment 1

[0017] (1) Put 10 g of ordinary water-absorbing fine-pore silica gel particles into a petri dish and place them in a vacuum drying oven with a set temperature of 100°C and a vacuum drying time of 4 hours to obtain silica gel after heat removal and pretreatment.

[0018] (2) Measure 75mL of n-heptane into a three-necked flask, then add 5mL of ethanol into the three-necked flask, mix well, then add 5mL of trimethylchlorosilane into the three-necked flask to prepare the required silane modifier.

[0019] (3) Add the silica gel treated in the above step 1 to the silane modifier prepared in the above step 2, impregnate at a temperature of 70°C for 10 hours (a condensation reflux device is provided during the impregnation process), filter, and use n-heptane Clean the residual silane modifier, then filter, repeat several times until there is no silane modifier in the filtrate, and then dry the modified silica gel in a vacuum oven at 80°C for 24 hours to remove n-heptane adsorbed on th...

Embodiment 2

[0021] (1) Put 10 g of ordinary water-absorbing fine-pore silica gel particles into a petri dish and place them in a vacuum drying oven with a set temperature of 100°C and a vacuum drying time of 4 hours to obtain silica gel after heat removal and pretreatment.

[0022] (2) Measure 75mL of n-heptane into a three-necked flask, then add 5mL of ethanol into the three-necked flask, mix well, then add 5mL of trimethylchlorosilane into the three-necked flask to prepare the required silane modifier.

[0023] (3) Add the silica gel treated in the above step 1 to the silane modifier prepared in the above step 2, impregnate at a temperature of 70°C for 1 hour, and then act at the same time for 10 minutes at an ultrasonic power of 500W at a temperature of 70°C, and then continue Immersion, so that the total time of immersion reaches 10h (a condensing reflux device is provided during the immersion process), then filter, and wash the residual silane modifier with n-heptane, then filter, rep...

Embodiment 3

[0025] In Example 2, the contents of Step 1 and Step 2 remained unchanged, and in Step 3, only the ultrasonic power was changed to 500 W for 20 minutes at the same time to obtain hydrophobic silica gel 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com