Method for preparing high-catalytic-activity hierarchical structure silver molybdate

A high catalytic activity, graded technology, applied in chemical instruments and methods, botanical equipment and methods, physical/chemical process catalysts, etc. The effect of good repeatability, long cycle life and broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

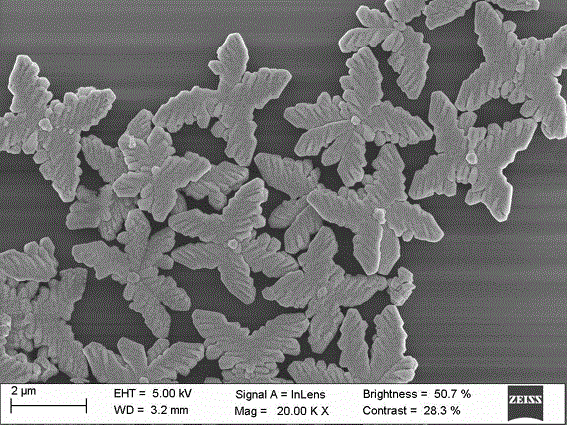

[0016] Weigh 1mmol of silver acetate, 1g of polyvinylpyrrolidone and 50ml of deionized water into a 100ml beaker, stir for 2 hours at 1000W power and ultrasonic for 1 hour to fully dissolve, add 0.1mol / L ammonium molybdate solution, and react at 30°C for 3 hours, centrifuge until neutral, and dry in an oven at 80°C for 6 hours. Its SEM photos are as figure 1 shown. The product is a butterfly-like structure composed of small particles.

[0017] Put it into 20mg / L methylene blue, and under the excitation of 410nm LED light source, the degradation rate can reach more than 96%.

Embodiment 2

[0019] Weigh 5mmol of silver nitrate, 3g of polyethylene glycol and 50ml of deionized water into a 100ml beaker, stir for 2 hours with 1200W power and ultrasonic for 1 hour to fully dissolve, add 0.5mol / L sodium molybdate solution, heat at 120°C for 4 hours , centrifuged until neutral, and dried in an oven at 60°C for 10 hours.

[0020] Put it into staphylococcus, and under the excitation of 410nm LED light source, the sterilization rate reaches 100%.

Embodiment 3

[0022] Weigh 5mmol of silver nitrate, 2g of ethylenediaminetetraacetic acid and 50ml of deionized water into a 100ml beaker, stir for 0.5 hours and ultrasonically at 1200W for 2 hours to fully dissolve, add 0.5mol / L sodium molybdate solution, at 50°C React for 4 hours, centrifuge until neutral, and dry in an oven at 80°C for 6 hours.

[0023] Putting it into a photo-splitting water hydrogen production reaction device, the quantum efficiency of hydrogen production can reach 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com