Vertical travelling mechanism for wind tower maintenance robot

A technology for wind power towers and traveling mechanisms, which is applied to motor vehicles, transportation and packaging, etc., can solve problems such as unusable, and achieve the effects of easy implementation, high work efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

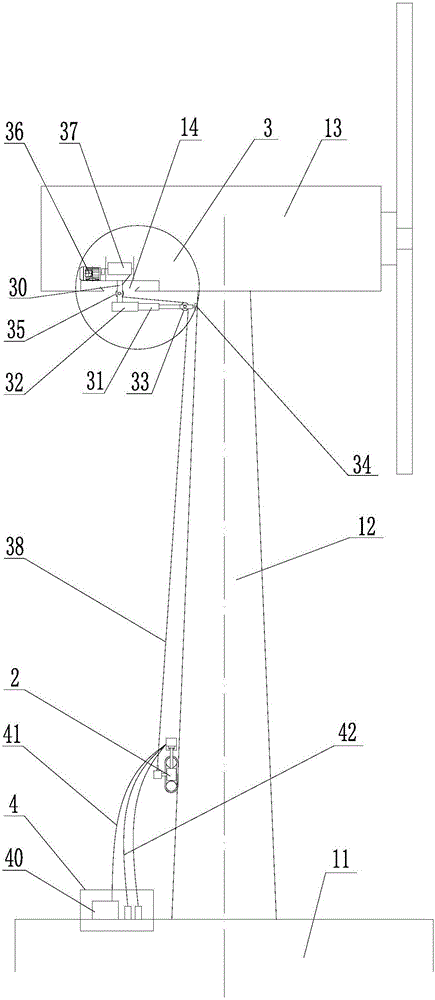

[0024] see figure 1 As shown in FIG. 2 , the wind power plant includes a platform 11 , a tower 12 and a nacelle 13 , and the bottom wall of the nacelle 13 is provided with a hoisting port 14 .

[0025] The up and down traveling mechanism of the wind power tower maintenance robot of the present invention includes a robot operation platform 2 , an operation platform traction mechanism 3 and a ground operation platform 4 .

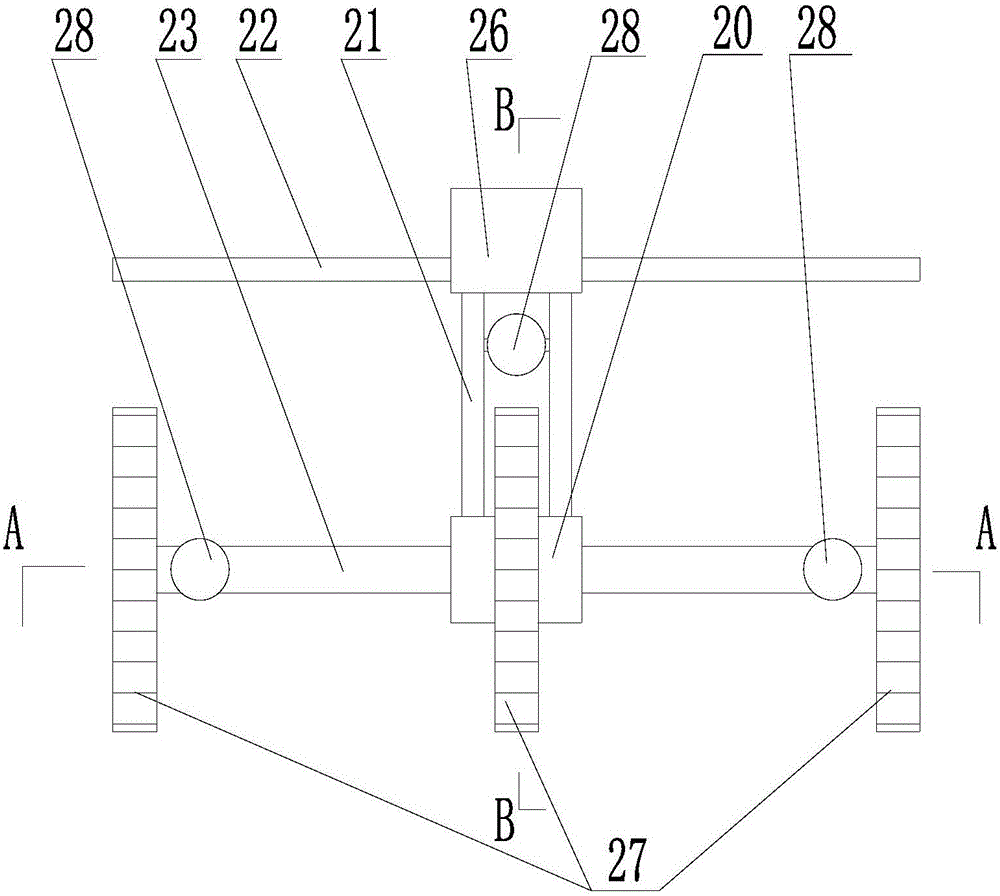

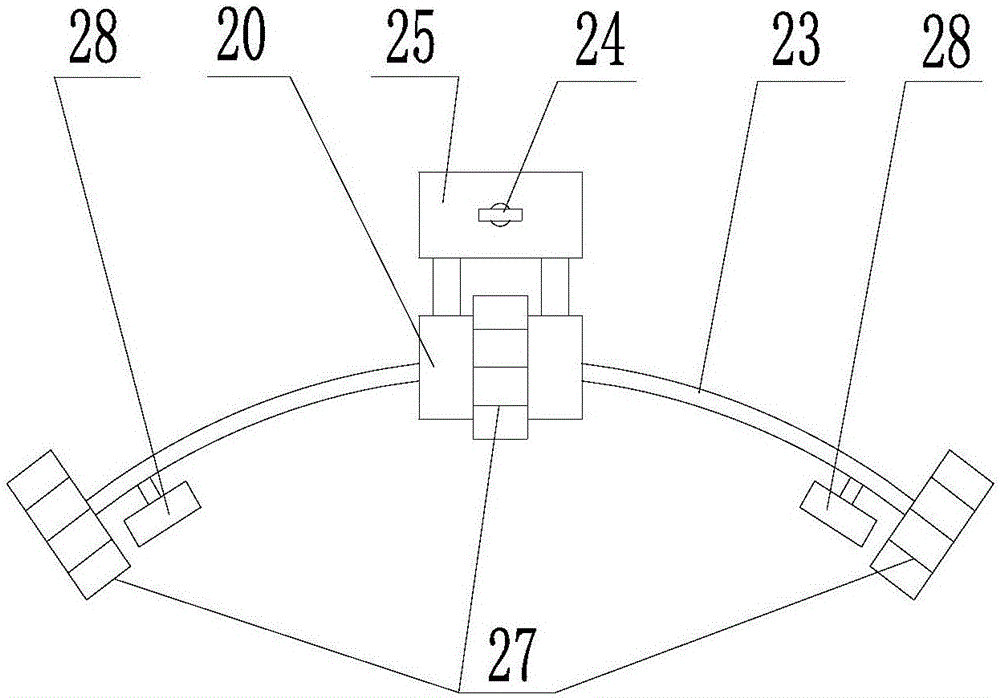

[0026] The robot operating platform 2 includes a support, a robot actuator 26, an up and down crawling mechanism 27 and a platform adsorption device 28; wherein:

[0027] The support includes a base body 20 with a perforation on the side, two vertical rods 21 fixed on the upper end surface of the base body 20, a laterally moving guide rail 22 fixed on the upper end of the vertical rod 21, and an elastic rod inserted in the perforation of the base body 20....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com