Method for preparing potassium nitrate and nanometer kaolinite with kaliophilite powder bodies

A technology of kalnite powder and kaolinite, which is applied in the field of fine chemical material preparation, can solve the problems of expensive potassium chloride, complex production process, dangerous and explosive ammonium nitrate, etc., and achieve good economic benefits, high resource utilization rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

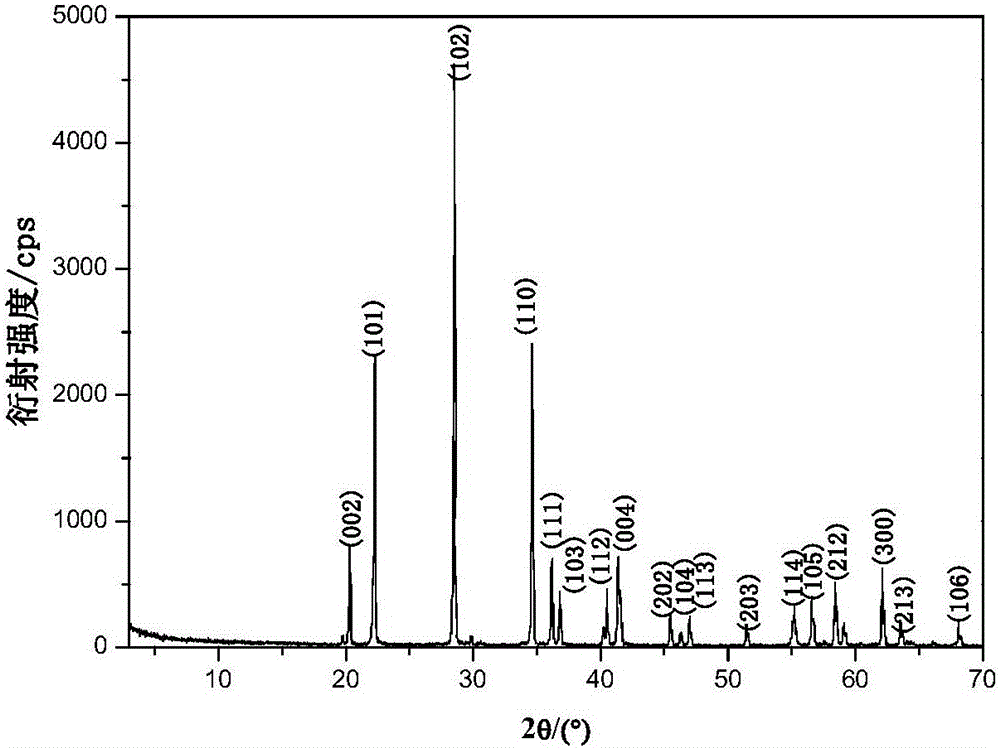

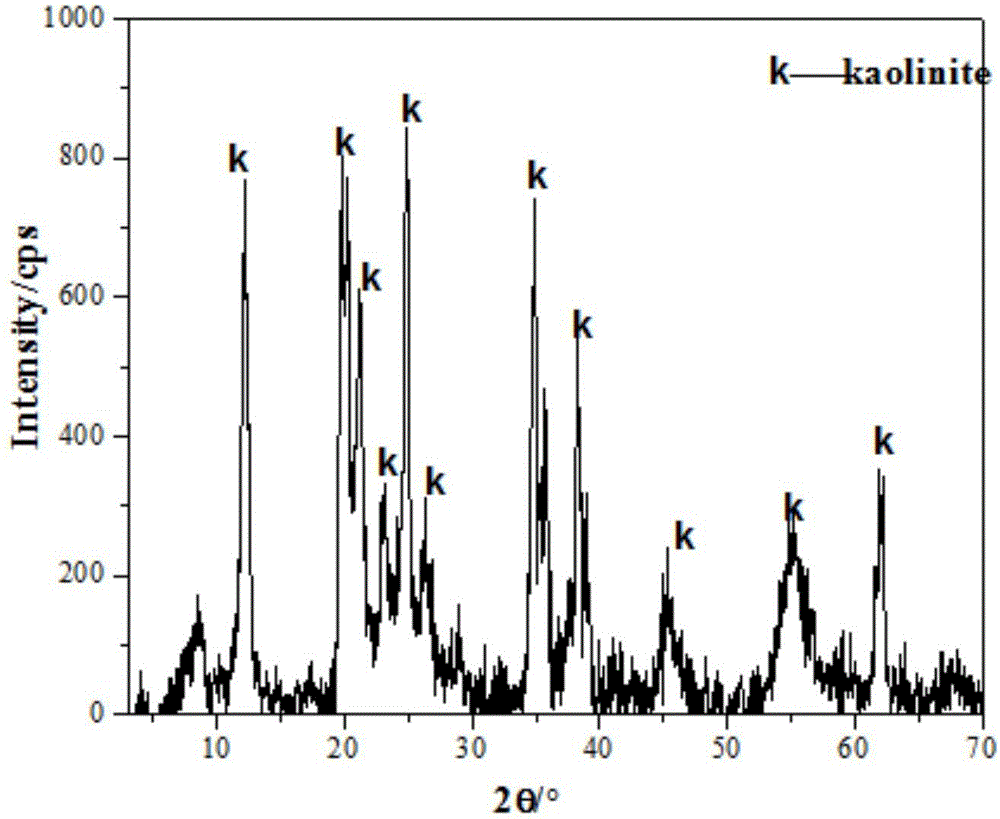

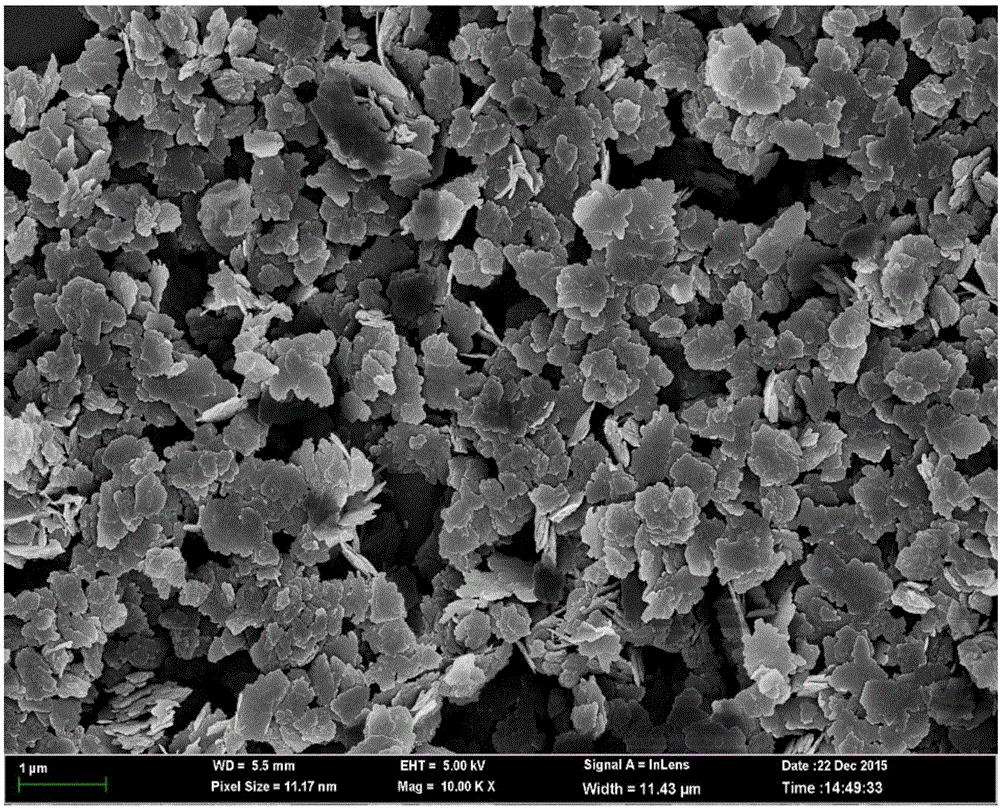

[0023] (1) The ka-nepheline powder used in this patent is obtained by hydrothermal treatment with the ko-nepheline powder as a raw material. Crystallographic diffraction analysis such as figure 1 . Index calculation is carried out on the X-ray powder crystal diffraction data of raw materials, and the lattice constant is basically consistent with the standard value of hexagonal kacryptite in the standard JCPDS card (card number 85-1413) (Table 2).

[0024] Table 1 The chemical composition analysis results (W B %)

[0025]

[0026] Table 2 Comparison of lattice constants of hexagonal kacryptite powder (S-01) and JCPDS standard card

[0027]

[0028] (2) accurately take by weighing ka-nepheline powder 7.5g (chemical composition analysis results are shown in Table 1), distilled water 55.4g, nitric acid (mass fraction is 66%) 4.6g, the nitric acid of 4.6g is added 20g distilled water and diluted, will Mix 7.5g of ka-nepheline powder and 35.4g of distilled water and stir e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com