Preparation method of vanadium pentoxide

A vanadium pentoxide and chlorination furnace technology, applied in the direction of vanadium oxide, etc., can solve the problems of ineffective treatment of waste residue and wastewater, high requirements for the preparation environment, and high equipment requirements, and achieve low cost, simple process flow, and short reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

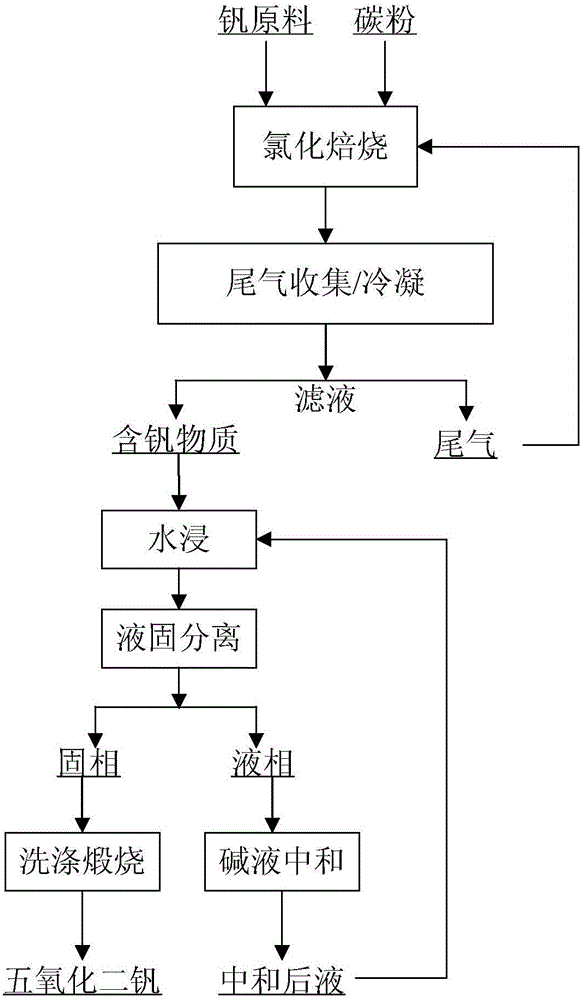

Method used

Image

Examples

Embodiment 1

[0058] (1) Calcium vanadate (containing V 2 o 5 About 35%) and carbon powder with a particle size of 100-150 μm are evenly mixed according to the molar ratio of vanadium element and carbon powder at 1:1.5, then placed in a tubular chlorination furnace, fed with chlorine gas and protective gas nitrogen and heated to 400 °C , chlorinated and roasted for 3 hours after the temperature was constant;

[0059] (2) Adopt gas collection device to collect the vanadium-containing gas that produces in the chlorination roasting process;

[0060] (3) Condensing the vanadium-containing gas at 120° C. through an adjustable spray and then cooling to room temperature to obtain a vanadium-containing substance with a vanadium oxychloride content of 99.95 wt%, and returning the tail gas obtained after condensation and cooling to step (1) for recycling;

[0061] (4) The obtained vanadium-containing substance is directly leached with pure water at 70°C and kept warm for 0.5h. After the reaction is...

Embodiment 2

[0064] (1) Calcium vanadate (containing V 2 o 5 About 35%) and carbon powder with a particle size of 20-50 μm are uniformly mixed according to the molar ratio of vanadium element and carbon powder at 1:2, then placed in a tubular chlorination furnace, fed with chlorine gas and protective gas argon and heated to 600 ℃, continue chlorination and roasting for 2 hours after the temperature is constant;

[0065] (2) Adopt gas collection device to collect the vanadium-containing gas that produces in the chlorination roasting process;

[0066] (3) Condensing the vanadium-containing gas at 125° C. for 0.5 to 1 h through an adjustable spray and then cooling to obtain a vanadium-containing substance with a vanadium oxychloride content of 99.95 wt%, and returning the tail gas obtained after condensation and cooling to step (1) for recycling ;

[0067] (4) The obtained vanadium-containing substance is directly leached with pure water at 50° C. and kept for 1 hour. After the reaction is...

Embodiment 3

[0070] (1) Calcium vanadate (containing V 2 o 5 About 35%) and carbon powder with a particle size of 200-250 μm are uniformly mixed according to the molar ratio of vanadium element and carbon powder at 1:1, then placed in a tubular chlorination furnace, and a mixture of chlorine gas and protective gas argon and neon is introduced Gas and heated to 500 ° C, after the temperature is constant, continue chlorination and roasting for 3 hours;

[0071] (2) Adopt gas collection device to collect the vanadium-containing gas that produces in the chlorination roasting process;

[0072] (3) Condensing the vanadium-containing gas at 100° C. for 0.5 to 1 h through adjustable spraying and then cooling to obtain a vanadium-oxychloride content of 99.91 wt % vanadium-containing substance, and returning the tail gas obtained after condensation and cooling to step (1) for recycling;

[0073] (4) The obtained vanadium-containing substance is directly leached with pure water at 70°C and kept war...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com