Linear low-density polyethylene/carbon nanotube open-cell foam material and method for preparing same

A linear low-density, carbon nanotube technology, applied in the field of linear low-density polyethylene foamed open-cell materials and polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

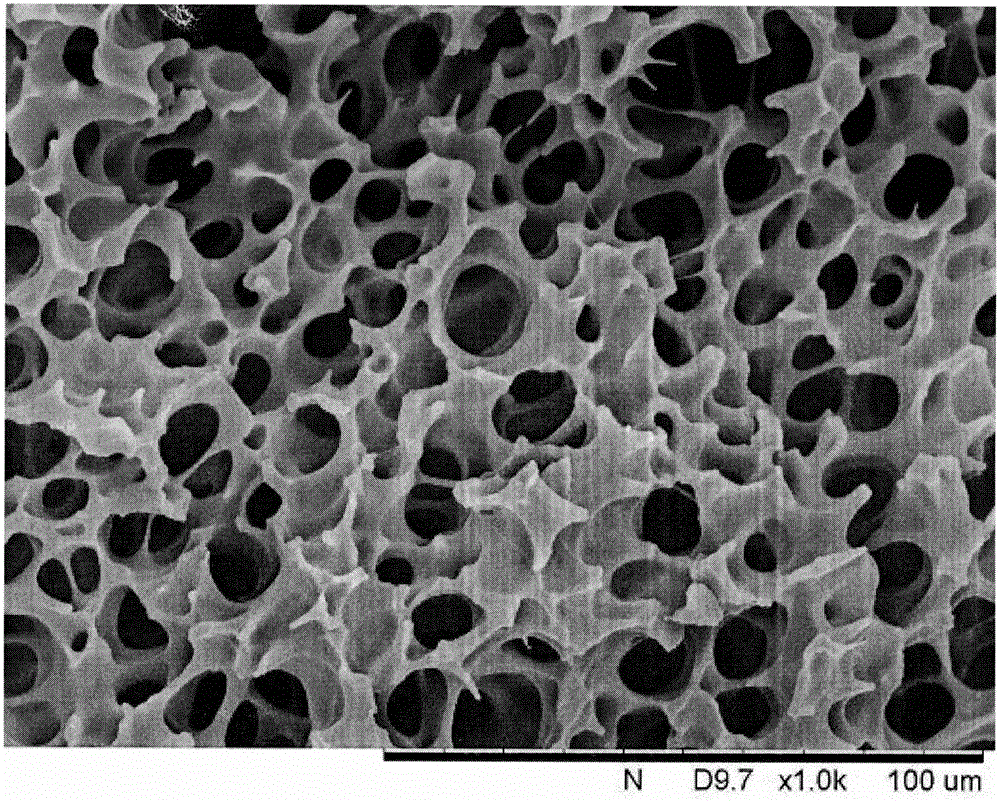

Image

Examples

preparation example Construction

[0030] The preparation method of the alkyl-modified carbon nanotubes can be prepared by covalent bond or non-covalent bond chemical method.

[0031] The chemical method of non-covalent bond can be obtained by selecting suitable surfactants to modify carbon nanotubes. Commonly used alkyl-containing surfactants can be used, such as sodium dodecylbenzenesulfonate and sodium dodecylsulfate. , Sodium dioctyl succinate sulfonate.

[0032] There are many chemical methods of covalent bonding, and there are many modification methods. For example, alkylamines can be grafted to carbon nanotubes to obtain alkyl-modified carbon nanotubes. Commonly used alkylamines include octadecylamine, hexadecylamine, and bidecylamine. Amine, decylamine, octylamine, etc.

[0033] In order to make the alkyl-modified carbon nanotubes and LLDPE have closer solubility parameters and better compatibility, the alkyl groups in the alkyl-modified carbon nanotubes and the linear low-density polyethylene and ethy...

Embodiment 1

[0062] The LLDPE composition is composed of 100 mass parts of linear low density polyethylene (Dow Chemical, HES-1003NT7) and 1 mass part of octane-modified carbon nanotubes (average diameter 8-15nm, average length 10 -30 μm, obtained by modifying carbon nanotubes with octylamine, modification conditions can refer to chem.Mater., 2003, volume 15, pages 3256-3260). The linear low-density polyethylene resin composition was blended in a Haake micro-mixing rheometer (HaakeMiniLab, ThermoElectron, Germany), blended for 40 minutes, controlled the screw speed at 50r / min, and controlled the temperature at 150 ° C, and then extruded The samples were pressed into 0.2 mm sheets.

[0063] The thin sheet of linear low-density polyethylene resin composition is put into high-pressure mould, and the temperature of control high-pressure mold is 136 ℃, and the thin sheet of linear low-density polyethylene resin composition accounts for 1 / 20 of high-pressure mold volume, injects in the high-pres...

Embodiment 2

[0066] The linear low density polyethylene composition is modified by 100 mass parts of linear low density polyethylene (Dow Chemical Company, Engage8200, ethylene-octene copolymerization, octene content: 7.3 mol %) and 1 mass part of octyl group Carbon nanotubes (average diameter 8-15nm, average length 10-30μm, obtained by modifying carbon nanotubes with octylamine, modification conditions can refer to chem.Mater., 2003, volume 15, pages 3256-3260). The linear low-density polyethylene resin composition was blended in a Haake micro-mixing rheometer (HaakeMiniLab, ThermoElectron, Germany), blended for 40 minutes, controlled the screw speed at 50r / min, and controlled the temperature at 150 ° C, and then extruded The samples were pressed into 0.2 mm sheets.

[0067] The thin sheet of linear low-density polyethylene resin composition is put into high-pressure mold, and the temperature of control high-pressure mold is 132 ℃, and the thin sheet of linear low-density polyethylene res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

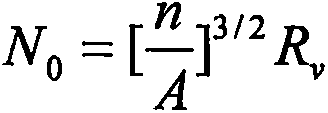

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com