Chemical copper plating agent and preparation method thereof

A technology of electroless copper plating and copper sulfate, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., and can solve problems such as non-compliance, physical injury of employees, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ① Add 30% deionized water to the container;

[0019] ② When stirring, add 0.04% EDTA-2Na (disodium ethylenediaminetetraacetic acid) according to the proportion, and stir for 25-30 minutes;

[0020] ③ While stirring, add 0.007% copper sulfate according to the ratio, and continue stirring for 25-30 minutes;

[0021] ④ When stirring, add 0.007% sodium hydroxide according to the proportion, and continue stirring for 25-30 minutes;

[0022] ⑤ When stirring, add 0.005% EDTP (tetrahydroxypropylethylenediamine) according to the proportion, and continue stirring for 25-30 minutes;

[0023] ⑥ When stirring, add 0.004% formaldehyde, 0.005% methanol, 0.05% adipic acid and 0.01% succinic acid according to the proportion, and continue stirring for 25-30 minutes;

[0024] ⑦Add water to the required amount, and stir well after completion.

Embodiment 2-5

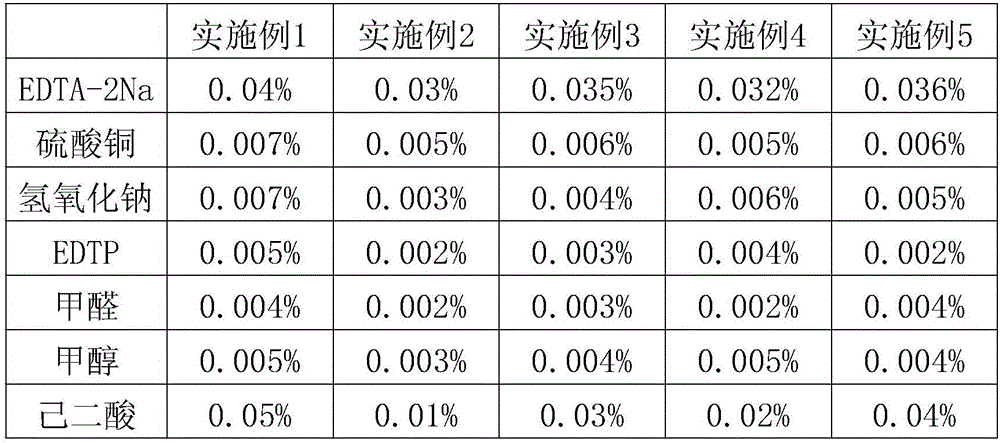

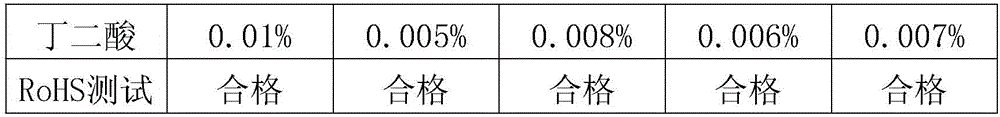

[0026] Repeat the method of Experimental Example 1 by the content of each component specified in Table 1 to obtain chemical copper plating agents of different proportions (omitting deionized water), and the obtained chemical copper plating agents are tested according to RoHS requirements.

[0027] Table 1:

[0028]

[0029]

[0030] The whole product to be plated is immersed in the middle of the electroless copper plating agent that embodiment 1-5 makes 30min, takes out and dries, and adopts CuCl 2 The system copper plating agent was used as a control example for testing.

[0031] The detection method is:

[0032] ①Adhesion test: Repeat the 3M tensile test of Baige 3 times to observe whether the coating has fallen off;

[0033] ②Double 85 test: place it in an environment with a temperature of 85°C and a humidity of 85%, and observe when the coating changes.

[0034] Table 2:

[0035]

[0036] As can be seen from Table 2, compared to CuCl 2 System copper pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com