Cold corrosion agent for displaying dendritic structure of 800 H nickel base corrosion resistant alloy and corrosion method

A technology of dendritic structure and corrosion-resistant alloy, applied in the field of metallographic inspection and analysis, can solve problems such as unsatisfactory erosion effect, need for electrolytic corrosion, complex configuration method, etc., achieve clear and accurate detection results, protect dendritic arms, formula simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

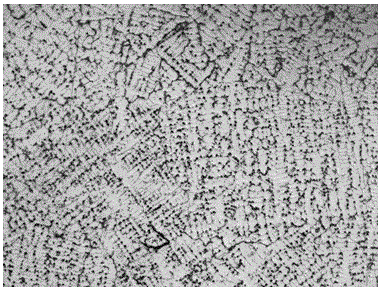

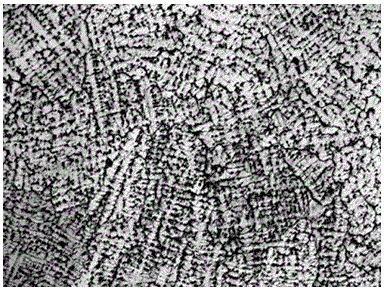

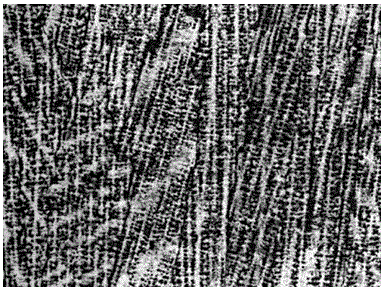

Image

Examples

Embodiment 1

[0027] First add 25ml of distilled water to the container, then add 4.0g of copper chloride, then pour in 20ml of hydrochloric acid, stir evenly and wait until the solid is completely dissolved, finally pour in 20ml of nitric acid, and stir continuously with a glass rod, that is, the configuration is successful. After the cold etchant is prepared, place it for 5 minutes before using it.

[0028] Cut a sample of 20mm×20mm×10mm from the equiaxed crystal structure on the slab, grind the sample on 150#, 400#, 600#, 1000#, 1500#, 2000# water sandpaper in turn, and then polish Use a polishing paste with a particle size of 2.5 μm on the machine to polish it into a mirror surface, and finally rinse the surface of the sample with alcohol and dry it with a hair dryer.

[0029] With the polished surface of the sample facing up, use a cotton ball dipped in cold etchant to gently wipe the polished surface for 2 seconds, and immediately rinse the sample with distilled water to observe wheth...

Embodiment 2

[0031] First add 30ml of distilled water to the container, then add 5.0g of copper chloride, then pour in 25ml of hydrochloric acid, stir evenly and wait until the solid is completely dissolved, finally pour in 25ml of nitric acid, and stir continuously with a glass rod, that is, the configuration is successful. After the cold etchant is prepared, place it for 5 minutes before using it.

[0032] Cut a sample of 20mm×20mm×10mm from the equiaxed crystal structure on the slab, grind the sample on 150#, 400#, 600#, 1000#, 1500#, 2000# water sandpaper in turn, and then polish Use a polishing paste with a particle size of 2.5 μm on the machine to polish it into a mirror surface, and finally rinse the surface of the sample with alcohol and dry it with a hair dryer.

[0033] With the polished surface of the sample facing up, use a cotton ball dipped in cold etchant to gently wipe the polished surface for 2 seconds, and immediately rinse the sample with distilled water to observe wheth...

Embodiment 3

[0035] First add 22ml of distilled water to the container, then add 4.2g of copper chloride, then pour in 23ml of hydrochloric acid, stir evenly and wait until the solid is completely dissolved, finally pour in 23ml of nitric acid, and stir continuously with a glass rod, that is, the configuration is successful. After the cold etchant is prepared, place it for 5 minutes before using it.

[0036]Cut a sample of 20mm×20mm×10mm from the equiaxed crystal structure on the slab, grind the sample on 150#, 400#, 600#, 1000#, 1500#, 2000# water sandpaper in turn, and then polish Use a polishing paste with a particle size of 2.5 μm on the machine to polish it into a mirror surface, and finally rinse the surface of the sample with alcohol and dry it with a hair dryer.

[0037] With the polished surface of the sample facing up, use a cotton ball dipped in cold etchant to gently wipe the polished surface for 2 seconds, and immediately rinse the sample with distilled water to observe whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com