Sepiolite printing gum and sepiolite printing paste and preparation methods and applications thereof

A printing paste and printing color paste technology, which is applied in the field of textile dyes, can solve the problems of rough hand feeling at the pattern, not bright color, poor printing color fastness, etc., and achieve low mining cost and environmental protection for enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 pure cotton poplin fabric reactive dye direct printing

[0046] (1) Prepare sepiolite printing paste with a mass concentration of 5%.

[0047] The paste formula is:

[0048] 1 part meerschaum

[0049] 4 parts sodium alginate

[0050] 95 parts of water

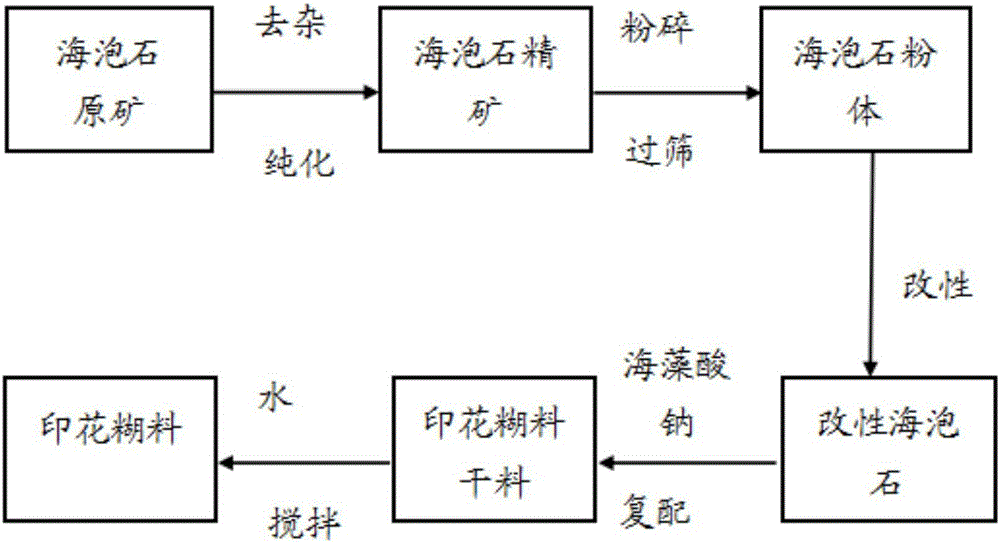

[0051] Prepared according to the following preparation process (such as figure 1 shown):

[0052] (a) Break the raw sepiolite (purity about 15%) mined from the mine to particles with a diameter of less than 0.5 cm, remove the impurity particles such as quartz sand, and purify the sepiolite concentrate (purity above 40%) .

[0053] (b) Using a high-speed pulverizer to pulverize the sepiolite concentrate particles to more than 200 meshes, and sieving with a molecular sieve to obtain sepiolite powder.

[0054] (c) using an acid modification method to remove metal ions and impurities in the sepiolite crystal structure, empty the cavity, improve its hygroscopicity and expansion, improve its thickening and ...

Embodiment 2

[0068] Embodiment 2 pure cotton poplin fabric reactive dye direct printing

[0069] (1) According to the preparation process of the aforementioned sepiolite printing paste, prepare the sepiolite printing paste with a mass concentration of 5%.

[0070] The paste formula is:

[0071] 2 parts meerschaum

[0072] 3 parts sodium alginate

[0073] 95 parts of water

[0074] And keep samples for basic performance test of sepiolite printing paste.

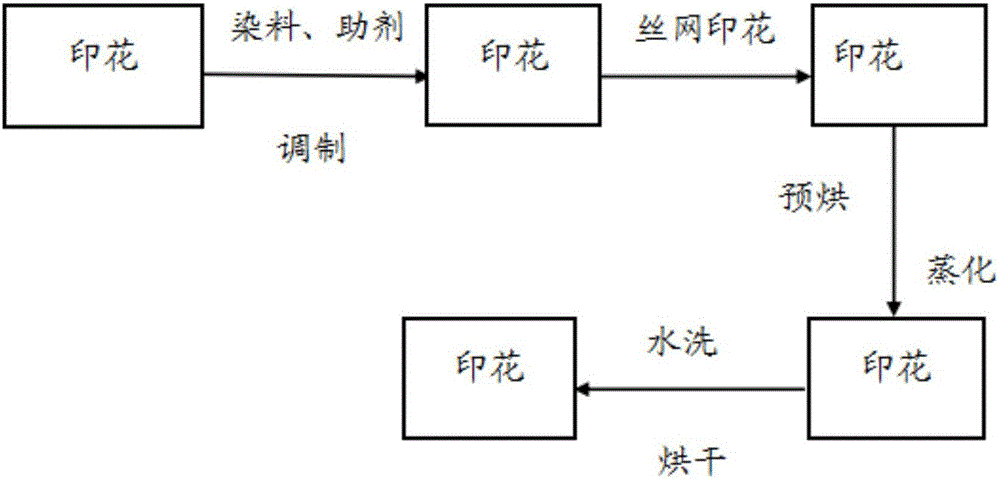

[0075] (2) Add dyes and auxiliaries to the printing paste, add water quantitatively, stir evenly, and prepare sepiolite printing paste.

[0076] Meerschaum printing color paste formula:

[0077]

[0078] (3) Carry out the printing operation according to the direct printing process of the aforementioned pure cotton poplin fabric reactive dyes.

[0079] (4) Put the printed fabric into the drying room and pre-dry it at about 95°C. Then send the dried fabric into the steamer, and act for 8 minutes at 100-103°C to obtain a semi-finish...

Embodiment 3

[0084] Embodiment 3 pure cotton poplin fabric reactive dye direct printing

[0085] (1) According to the aforementioned sepiolite printing paste preparation process, prepare printing paste with a mass concentration of 5%.

[0086] The formula of sepiolite printing paste is:

[0087] Meerschaum 3%

[0088] Sodium Alginate 2%

[0089] Water 95%

[0090] And retain the sample for the basic performance test of the paste.

[0091] (2) Add dyes and additives to the sepiolite printing paste, add water in a fixed amount, stir evenly, and prepare the sepiolite printing paste.

[0092] Meerschaum printing color paste formula:

[0093]

[0094] (3) Carry out the printing operation according to the direct printing process of the aforementioned pure cotton poplin fabric reactive dyes.

[0095] (4) Put the printed fabric into the drying room and pre-dry it at about 95°C. Then send the dried fabric into the steamer, and act for 8 minutes at 100-103°C to obtain a semi-finished print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com