Optical film and method for producing optical film

A manufacturing method and technology of optical film, applied in the field of optical film, can solve the problems of increasing manufacturing cost, increasing the thickness of adhesive material layer, etc., and achieve the effect of excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0212] Hereinafter, the present invention will be more specifically described based on examples, but the present invention is not limited to the following examples.

[0213] "Production of Sample 1"

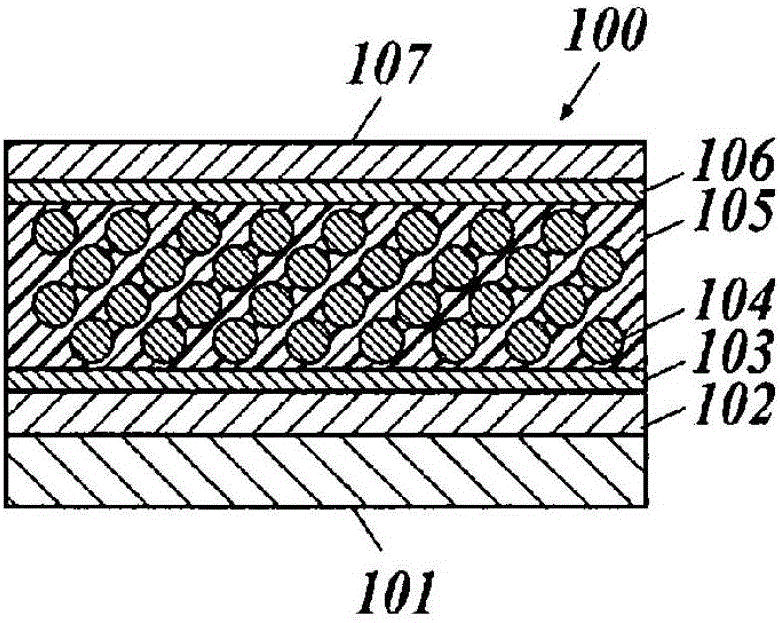

[0214] (1) Preparation of substrate

[0215] As a base material, a polyethylene terephthalate film (manufactured by Toyobo Co., Ltd., Cosmoshine A4300, abbreviated as PET) with a thickness of 125 μm that was processed to facilitate adhesion on both sides was used as a thermoplastic resin support. , The substrate was stored in an environment with a temperature of 25° C. and a relative humidity of 55% for 96 hours to perform humidity control.

[0216] On the easy-adhesive surface of the above-mentioned substrate, after coating OPSTAR (registered trademark) Z7501, a UV-curable organic / inorganic hybrid hard coat material manufactured by JSR Corporation, with a wire bar so that the layer thickness after drying becomes 4 μm, the coating was carried out at 80 After drying for 3 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com