Preparation method of highly-hydrophobic silicon dioxide aerogel

A hydrophobic silica and airgel technology, applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., can solve the problems of low mechanical performance and poor recycling rate, so as to improve mechanical performance and oil absorption The effect of increasing the amount and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

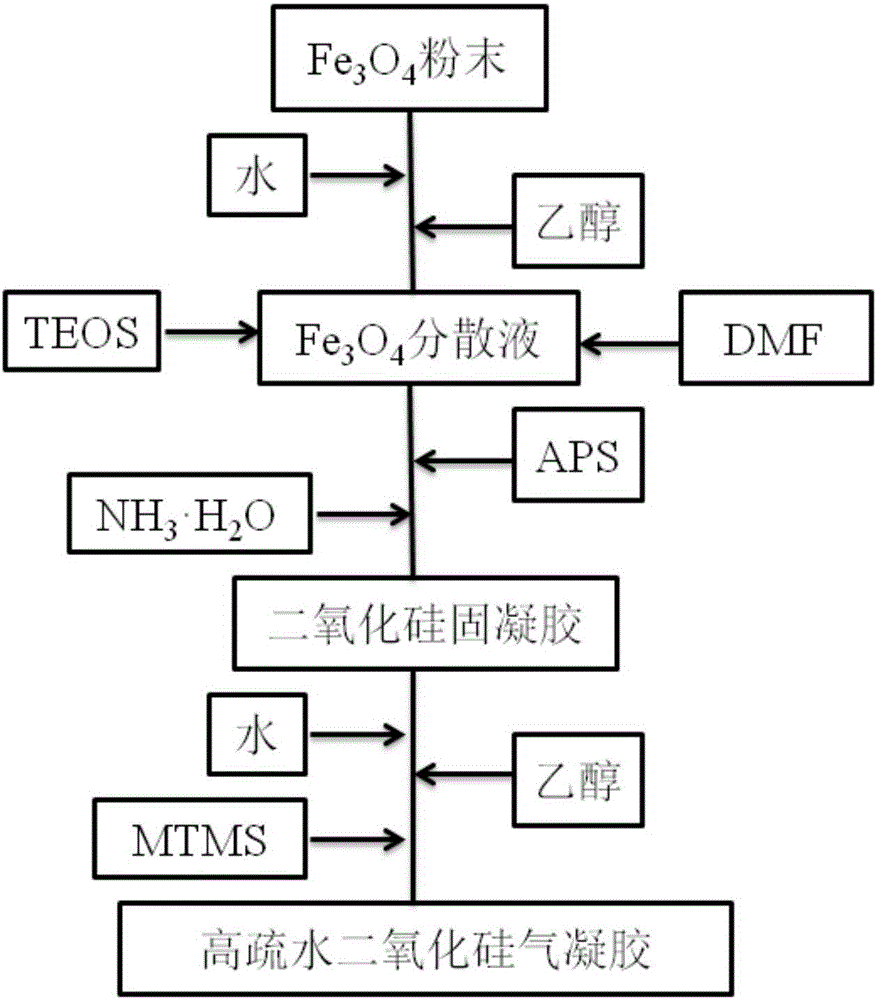

[0024] A kind of preparation method of highly hydrophobic silica airgel of the present invention, specific preparation process is as follows figure 1 shown, including the following steps:

[0025] In the first step, the Fe 3 o 4 Ultrasonic dispersion in 8-12mL of ethanol aqueous solution with a mass fraction of 40%-60% to form Fe with a mass concentration of 1.1mg / mL 3 o 4 Uniform dispersion.

[0026] In the second step, add 2-3mL of TEOS, 2-3mL of DMF and 1.8-2.2mL of APS to the homogeneous dispersion obtained in the first step, stir it evenly with ultrasonic waves, then transfer the mixture into a sealed glass bottle and continue mechanically The stirring hydrolysis reaction completely obtains the solid gel precursor;

[0027] In the third step, 0.9-1.1 mL of NH 3 ·H 2 O is added to the solid gel precursor and left to stand to form a silica solid gel;

[0028] In the fourth step, add 6-8 mL of ethanol solution with a mass fraction of 50% and 1.8-2.2 mL of MTMS for se...

Embodiment 1

[0030] In the first step, the Fe 3 o 4 Ultrasonic dispersion in 8mL ethanol aqueous solution, ultrasonic dispersion at 25°C for 15min, to form Fe with a mass concentration of 1.1mg / mL 3 o 4 Uniform dispersion, wherein the ethanol solution is composed of 5mL absolute ethanol and 3mL deionized water;

[0031] In the second step, add 2mL of TEOS, 2mL of DMF and 1.8mL of APS to the uniform dispersion obtained in the first step, sonicate for 10min until uniform, then transfer the mixture into a sealed glass bottle and continue mechanical stirring for 5h to obtain solidification Glue precursor;

[0032] In the third step, 0.9 mL of NH 3 ·H 2 O was added to the solid gel precursor and left to stand for 5 minutes to form a silica solid gel;

[0033] In the fourth step, 6 mL of ethanol solution with a mass fraction of 50% and 1.8 mL of MTMS were added for self-assembly for 16 hours. After the reaction, they were washed several times with absolute ethanol and deionized water, and ...

Embodiment 2

[0035] In the first step, the Fe 3 o 4 Ultrasonic dispersion in 10mL ethanol aqueous solution, ultrasonic dispersion at 25°C for 15min, to form Fe with a mass concentration of 1.1mg / mL 3 o 4 Uniform dispersion, wherein the ethanol solution is composed of 6mL absolute ethanol and 4mL deionized water;

[0036] In the second step, add 2.5mL of TEOS, 2.5mL of DMF and 2.0mL of APS to the uniform dispersion obtained in the first step, sonicate for 15min until uniform, then transfer the mixture into a sealed glass bottle and continue to stir mechanically for 6h to obtain solid gel precursor;

[0037] In the third step, 1.0 mL of NH 3 ·H 2 O was added to the solid gel precursor and left to stand for 7 minutes to form a silica solid gel;

[0038] In the fourth step, 7 mL of ethanol solution with a mass fraction of 50% and 2.0 mL of MTMS were added for self-assembly for 17 hours. After the reaction, they were washed several times with absolute ethanol and deionized water, and drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com