Preparation method of temperature-sensitive graphene oxide-based imprinted polymer and application thereof

An imprinted polymer and graphene-based technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of increasing the difficulty of detection and processing, and achieve the effect of solving the disadvantage of elution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

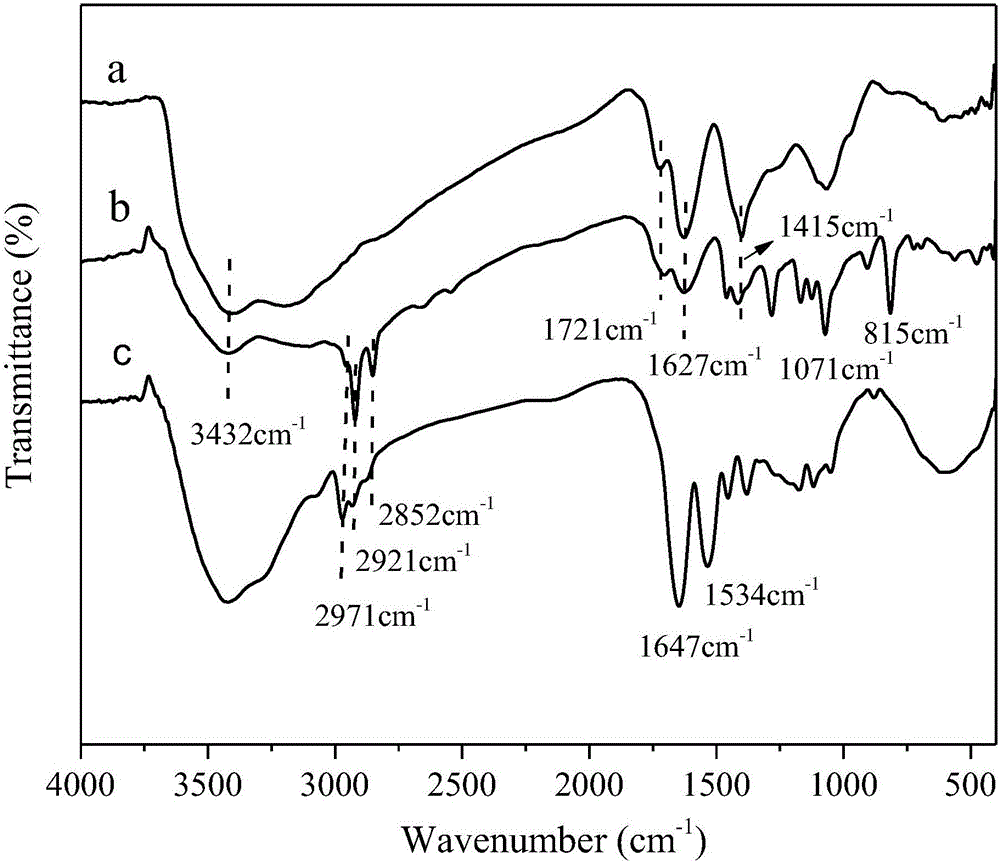

[0031] (1) Preparation of graphene oxide modified by RAFT reagent (GO-RAFT)

[0032] Graphene oxide (GO) used in the present invention is synthesized (W.S.Hummers, R.E.Offeman.Preparationofgraphiticoxide.Journal of the American Chemical Society, 1958,80 (6): 1339-1339) according to the classic Hummers method reported in literature, RAFT reagent is according to S-n-dodecyl-S'-(2-methyl-2-propionyl) trithiocarbonate (DDMAT) (J.T.Lai, D.Filla, R.Shea. Functional polymers from novel carboxyl-terminated trithiocarbonates highly efficient RAFT agents. Macromolecules, 2002, 35(18):6754-6756). Then, through the condensation reaction between the hydroxyl groups on the GO surface and the carboxyl groups on the DDMAT, the RAFT reagent is grafted onto the GO surface. The specific steps are as follows (this step is an existing method):

[0033] Take 50mg of GO and disperse in 50mL of dimethyl sulfoxide (DMF) solvent, ultrasonically disperse for 30min, and add 109.3mg of DDMAT after it is ...

Embodiment 2

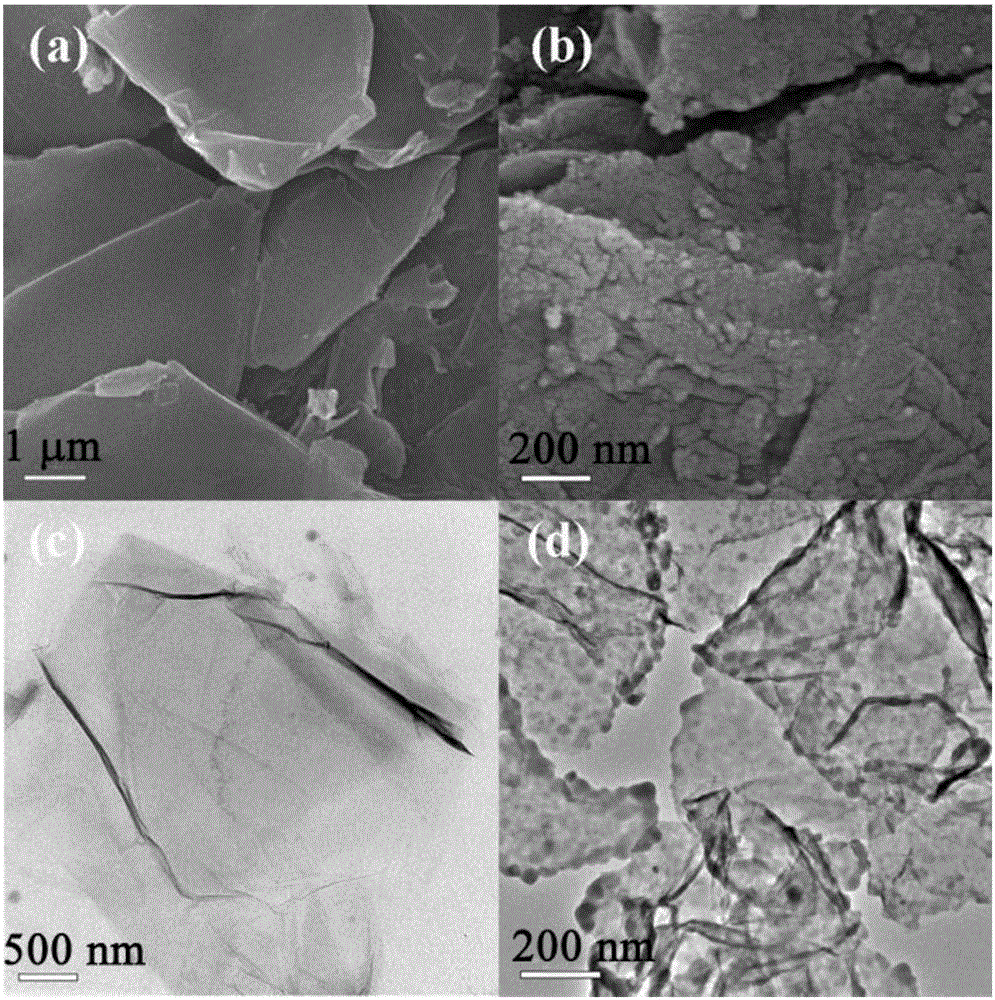

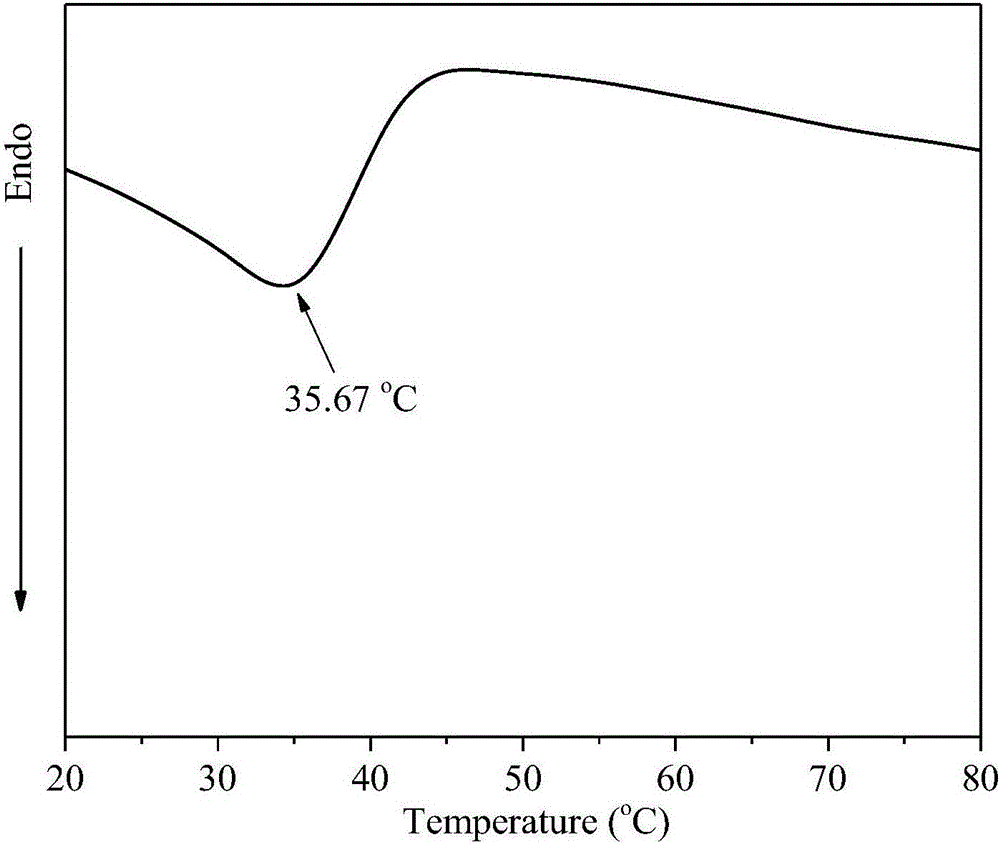

[0044] (1) Preparation of temperature-sensitive graphene oxide-based imprinted polymer (GT-MIP)

[0045] Graphene oxide modified by RAFT reagent (GO-RAFT) was prepared as described in Example 1.

[0046] Take 27.8mg of p-NP and 50μL of MAA and add it to 5mL of dilute ethanol solution, oscillate to disperse evenly, and keep it in a dark place for 12h. Then, in a quartz conical flask with a stopper, 40 mg of the synthesized GO-RAFT was added to 20 mL of dilute ethanol solution, and after ultrasonic dispersion, 112 mg of NIPAM, 154 mg of MBA, pre-polymerization solution and 10 μL of HMPF were successively added to the mixture . Disperse evenly, stir with magnetic force, and seal with nitrogen gas for deoxygenation. Then light reaction for 2h. After the reaction, centrifuge and wash several times with dilute ethanol solution to remove unreacted residual monomers and cross-linking agents. Then re-disperse in an aqueous solution containing 5% acetic acid, first stir at room temp...

Embodiment 3

[0053] (1) Preparation of temperature-sensitive graphene oxide-based imprinted polymer (GT-MIP)

[0054] Graphene oxide modified by RAFT reagent (GO-RAFT) was prepared as described in Example 1.

[0055] Take 13.9 mg of p-NP and 25 μL of MAA and add it to 5 mL of dilute ethanol solution, oscillate to disperse evenly, and keep it in a dark place for 12 hours. Then, in a quartz conical flask with a stopper, 50 mg of the synthesized GO-RAFT was added to 20 mL of dilute ethanol solution. After ultrasonic dispersion was uniform, 56 mg of NIPAM, 77 mg of MBA, pre-polymerization solution and 5 μL of HMPF were successively added to the mixture. . Disperse evenly, stir with magnetic force, and seal with nitrogen gas for deoxygenation. Then light reaction for 4h. After the reaction, centrifuge and wash several times with dilute ethanol solution to remove unreacted residual monomers and cross-linking agents. The template molecules were eluted according to Example 1, and then freeze-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com