Antistatic agent, antistatic polyamide composition, and preparation methods of antistatic agent and antistatic polyamide composition

A technology of polyamide composition and antistatic agent, which is used in the manufacture of conductive/antistatic filaments, single-component polyamide rayon, etc., can solve the problem of affecting the mechanical strength, heat resistance of molded products, increasing production costs, etc. problems, to achieve uniform antistatic performance, prolong service life, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039]

[0040] The preparation method of the antistatic agent comprises the following steps: uniformly mixing polyethylene glycol type antistatic agent solution and expanded graphite, stirring for 4-6 hours, separating solid and liquid, and drying to obtain the antistatic agent.

[0041] Wherein, the preparation method of polyethylene glycol type antistatic agent solution comprises the steps of: mixing polyethylene glycol type antistatic agent and organic solvent in a flask, heating to impel polyethylene glycol type antistatic agent to dissolve completely, that is Can.

[0042] The organic solvent is an organic solvent capable of dissolving the polyethylene glycol antistatic agent, preferably any one or a combination of both of methanol and ethanol, and the ethanol is preferably absolute ethanol.

[0043] The mass ratio of the polyethylene glycol antistatic agent mixed with the organic solvent is preferably (2-8):(30-40), preferably (3-5):(30-35), more preferably 4:30. The...

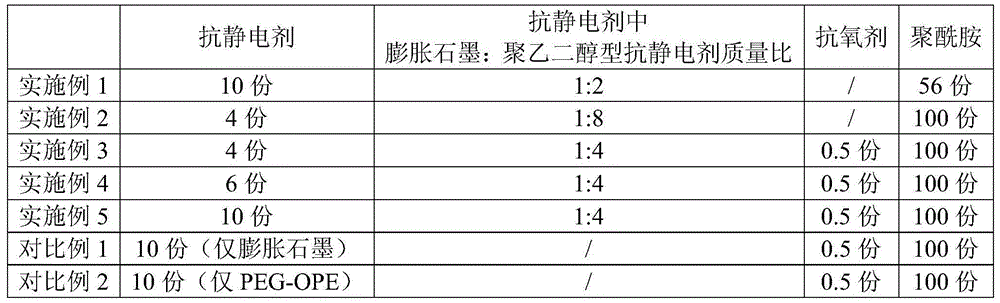

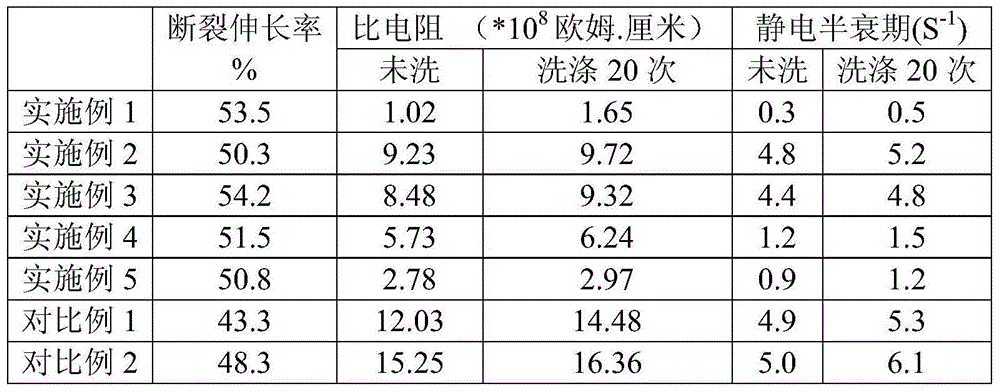

Embodiment 1

[0088] The preparation method of antistatic polyamide fiber comprises the steps:

[0089] (1) Add the polyethylene glycol-type antistatic agent PEG-OPE containing ether bonds into the flask, add an appropriate amount of absolute ethanol as a solvent, the mass ratio of PEG-OPE and absolute ethanol is 4:30, and heat in a water bath to 70°C, after the PEG-OPE is completely dissolved (that is, when the solution becomes transparent), add expanded graphite (EG), stir and react for 5 hours, evaporate the solution, put it in a vacuum oven for 24 hours, take it out and grind it into powder, and the anti-oxidant Static agent.

[0090] (2) 10 parts by weight of the antistatic agent obtained in step (1) and 56 parts by weight of polyamide were mixed in a high-speed mixer at a speed of 400 rpm for 5-10 minutes to obtain an antistatic polyamide 56 composition.

[0091] (3) Dry the antistatic bio-based polyamide 56 composition obtained in step (2) in a vacuum drying oven until the moisture ...

Embodiment 2

[0094] The preparation method of antistatic polyamide fiber comprises the steps:

[0095] (1) Add the polyethylene glycol-type antistatic agent PEG-OPE containing ether bonds into the flask, add an appropriate amount of absolute ethanol as a solvent, the mass ratio of PEG-OPE and absolute ethanol is 5:35, and heat in a water bath to 75°C, after PEG-OPE is completely dissolved (that is, when the solution becomes transparent), add high-conductivity expanded graphite (EG), stir and react for 6 hours, evaporate the solution, put it in a vacuum oven for 24 hours, take it out and grind it into powder, that is Get an antistatic agent.

[0096] (2) 4 parts by weight of the antistatic agent obtained in step (1) and 100 parts by weight of polyamide were mixed in a high-speed mixer at a speed of 600 rpm for 10 minutes to obtain an antistatic polyamide 56 composition.

[0097] (3) drying the antistatic bio-based polyamide 56 composition obtained in step (2) in a vacuum drying oven until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com