A kind of thermoplastic polyurethane composite foam material and preparation method thereof

A thermoplastic polyurethane and composite foaming technology, applied in the field of materials, can solve problems such as irrationality, material stiffness, rebound, compression resistance and other performance degradation, and achieve the effects of reducing physical energy consumption, simple production process, and suitable operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Corresponding present invention also provides the preparation method of this thermoplastic polyurethane composite foaming material, comprises the following steps:

[0053] 1) Weigh the following components by mass parts: 10-25 parts of thermoplastic polyurethane, 35-45 parts of ethylene-vinyl acetate copolymer, 15-30 parts of polyolefin elastomer, 6-10 parts of polyethylene, EPDM rubber 6-18 parts, polybutadiene polymer 6-15 parts, filler 3-5 parts, stearic acid St0.4-0.6 parts, zinc stearate ZnSt0.8-1.4 parts;

[0054] 2) Put all the ingredients weighed in step 1) into a twin-screw extruder for mixing, the mixing time is 8 minutes to 10 minutes, and the temperature is 110°C to 115°C;

[0055] 3) The following components are weighed in parts by mass: 1.5-2.2 parts of zinc oxide ZnO, 0.1-0.4 parts of crosslinking agent, 0.7-1.0 parts of bridging agent and 2.5-3.5 parts of foaming agent;

[0056] 4) Add all the ingredients weighed in step 3) to the mixed materials in ste...

Embodiment 1~2

[0062] Embodiment 1~2, comparative example 1

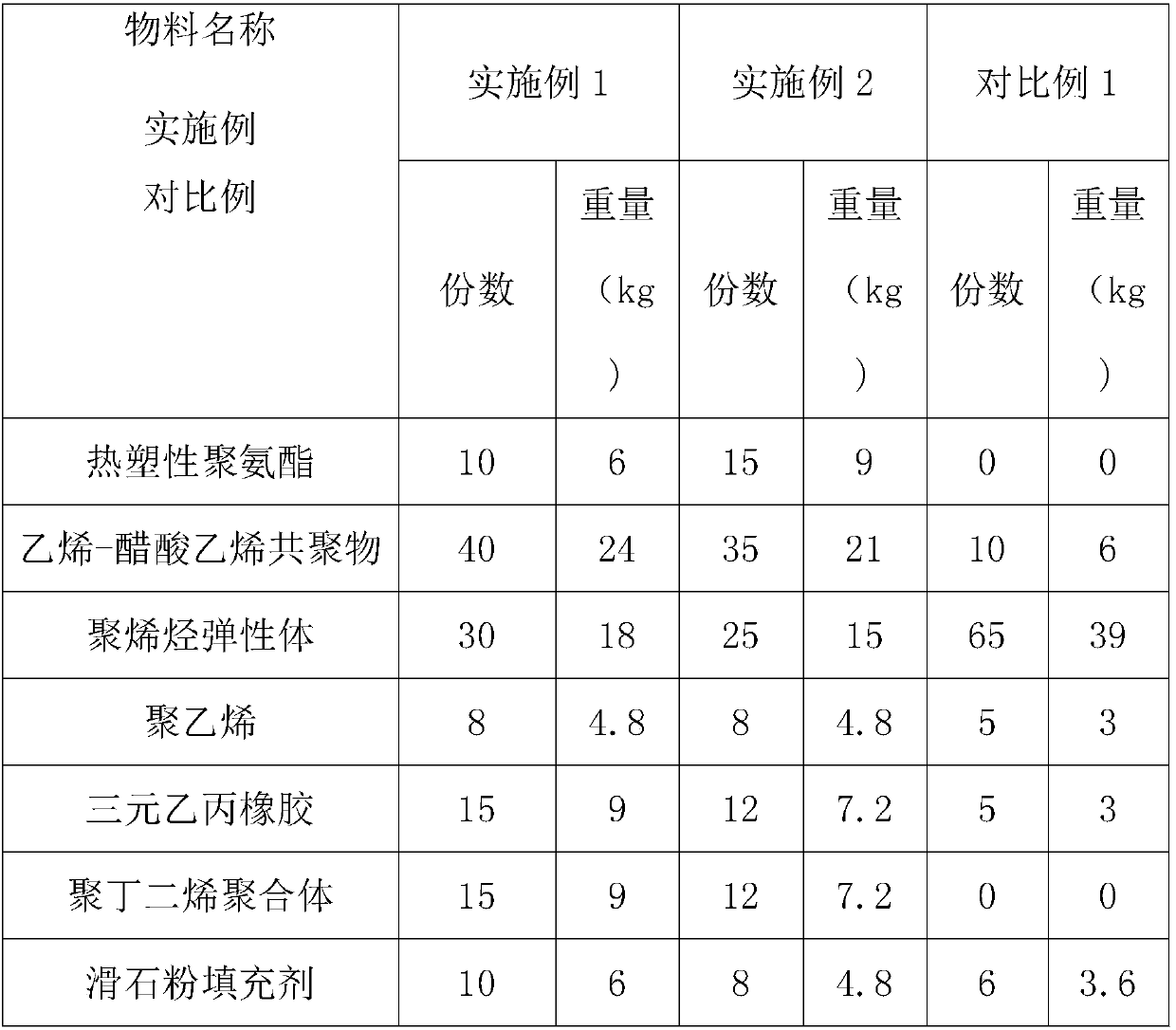

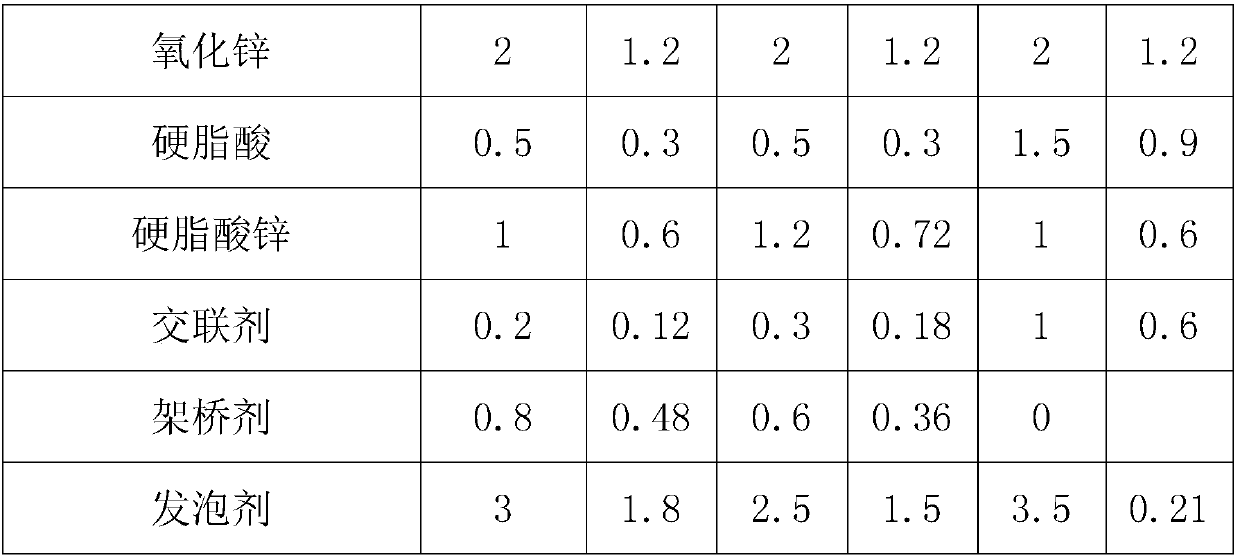

[0063] Table 1: Blending formula of thermoplastic polyurethane composite foam material (parts)

[0064]

[0065]

[0066] Among them, the thermoplastic polyurethane is F160, the polyolefin thermoplastic elastomer is selected as Engage8450 and Engage8150, and the ratio of the two is 1:1; the polyethylene is selected as LDPE6520; the ethylene-vinyl acetate copolymer is selected as EVA40L-03; The selected model of EPDM rubber is IP3745.

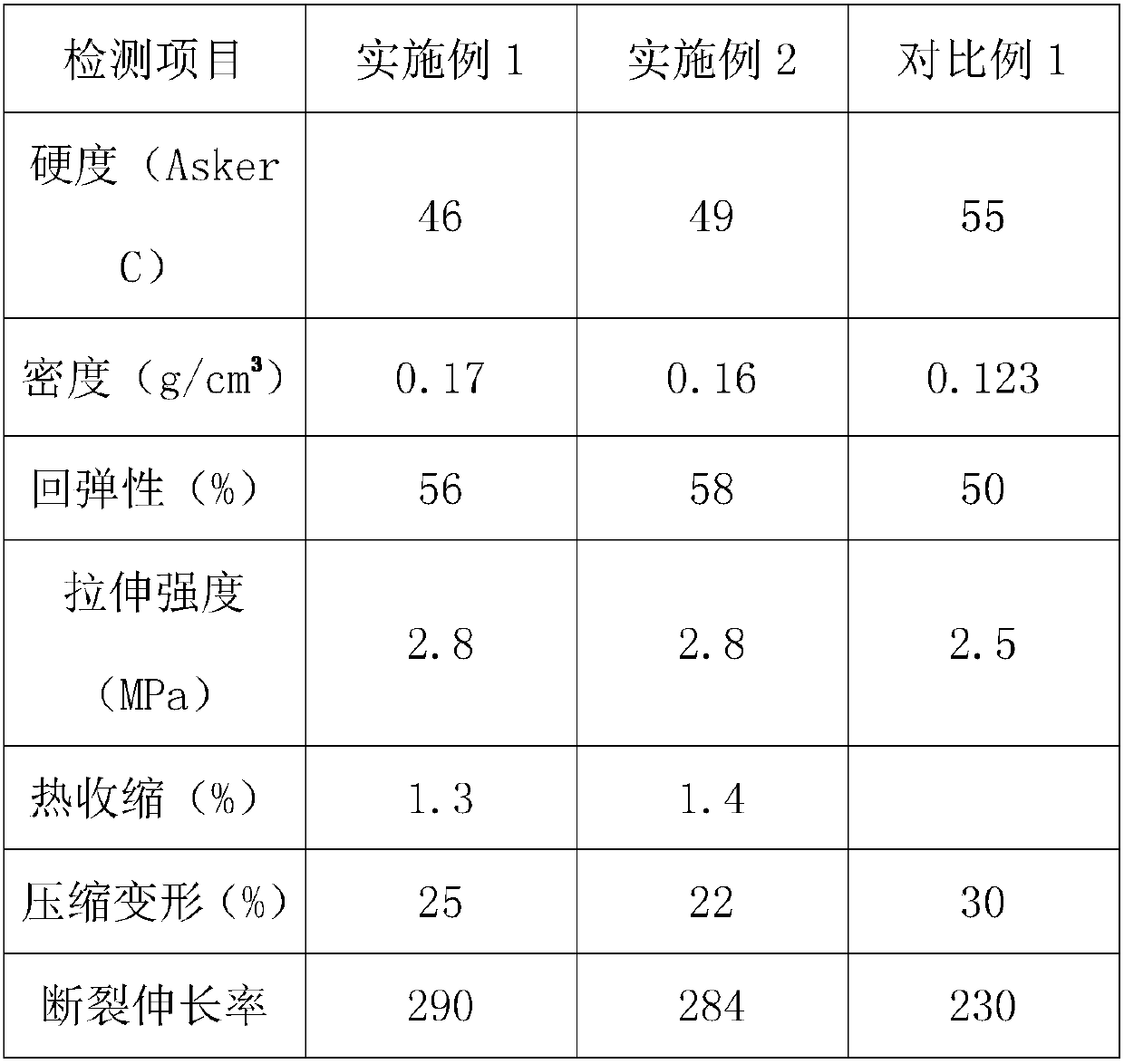

[0067] Table 2: Properties of the thermoplastic polyurethane composite foam material obtained in Examples 1-2 and Comparative Example 1

[0068]

[0069]

[0070] Note: The data in Table 2 is the data obtained according to the national standard test method.

[0071] From the data described in Table 2, it can be seen that the thermoplastic polyurethane composite foaming material prepared by thermoplastic polyurethane in the present invention can obtain very ideal shoe material functiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com