Carbon material-containing lubricating grease and preparation method thereof

A technology of lubricating grease and carbon material, applied in the field of lubricating grease, can solve the problems of complicated and cumbersome test methods for practicality, ignoring test methods, etc., and achieve the effect of reducing temperature, maintaining normal operation, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

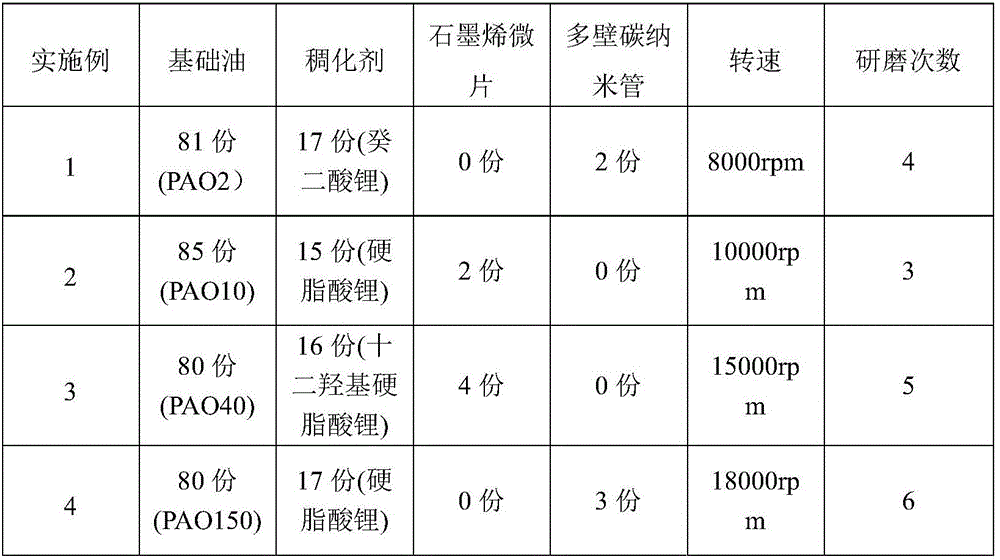

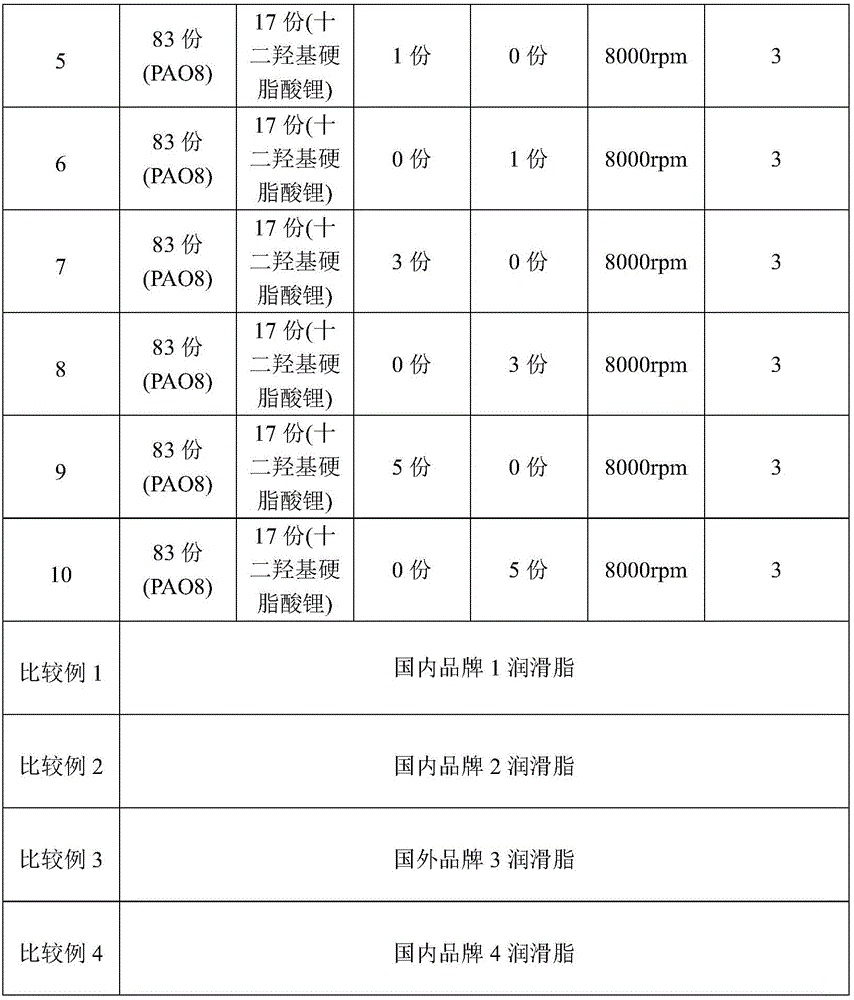

[0018] The preparation method is: first weigh a certain amount of base oil thickener, stir the base oil and thickener with a glass rod, then add the mixture to the colloid mill, set a certain speed, grind several times, and then grind the mixture Stir and heat, the temperature is set at 220°C, and the heating time is 0.5h. After the heating is completed, add a certain amount of additives, stir and cool to room temperature, and then use a three-roller to grind the finished product. See Table 1 for details.

[0019] The base oil is polyalphaolefin (PAO2, PAO8, PAO10, PAO40, PAO150), the thickener is lithium lauryl stearate, lithium stearate or lithium sebacate, and the additives are graphene microflakes, multi-walled One of the carbon nanotubes.

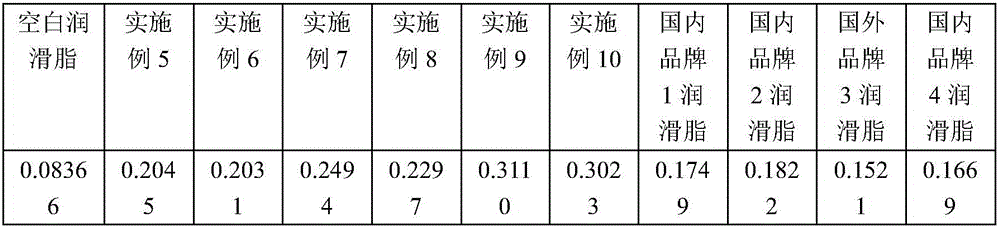

[0020] Table 1. Lithium-based grease formula and process table compared with commercial grease

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com