Ceramic coated automotive heat exchanger components

A technology for heat exchangers and ceramic coatings, which can be applied to heat exchange equipment, vehicle parts, coatings, etc., and can solve problems such as large size and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

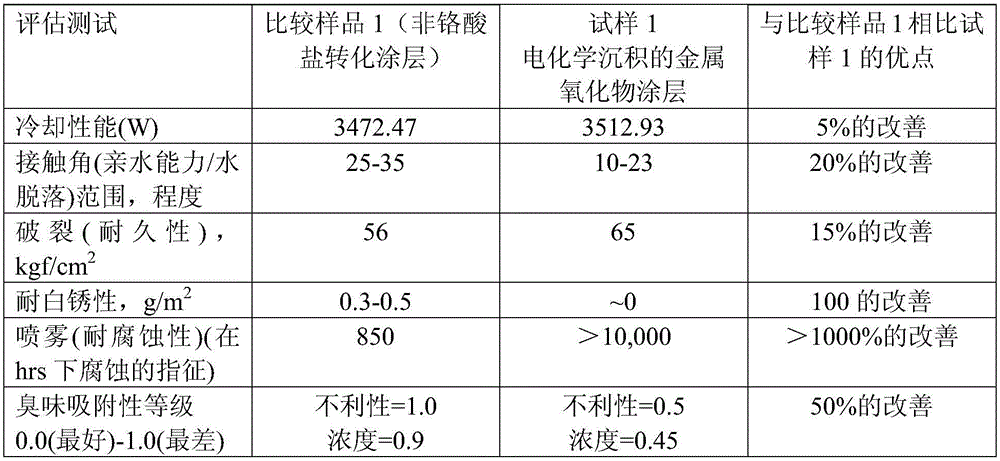

[0119] Comparative sample 1

[0120] Methods for preparing protective coatings on heat exchanger components using non-chromate chemical conversion methods are known in the art. For example, U.S. Patent No. 7,353,863, Serial No. 10 / 844,610 to Denso Corporation, issued April 2008 (incorporated herein by reference) uses a non-chromate conversion method in which the heat exchanger is pretreated with an etchant comprising an aqueous base solution. The etched substrate is then chemically converted or treated to increase hydrophilicity. The aluminum base of the heat exchanger, comprising a plurality of magnesium-containing aluminum alloy fins and tubes connected to each other by vacuum welding, is contacted with an aqueous pretreatment liquid. This pretreated substrate was subjected to an etching process using an aqueous alkaline solution in the manner shown below, and then to a descaling (pickling) process in the manner shown below. The etched substrate was then subjected to a non...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com