Production and application of Pt-SnO2 oxide semiconductor carbon monoxide sensor

A technology of oxide semiconductor and carbon monoxide, which is applied in the detection of carbon monoxide concentration in mines and atmospheric environments. In the field of Pt-SnO2 oxide semiconductor carbon monoxide sensor preparation, it can solve the problems of low sensitivity and high detection limit of the sensor, and achieve high sensitivity, The effect of low detection limit and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

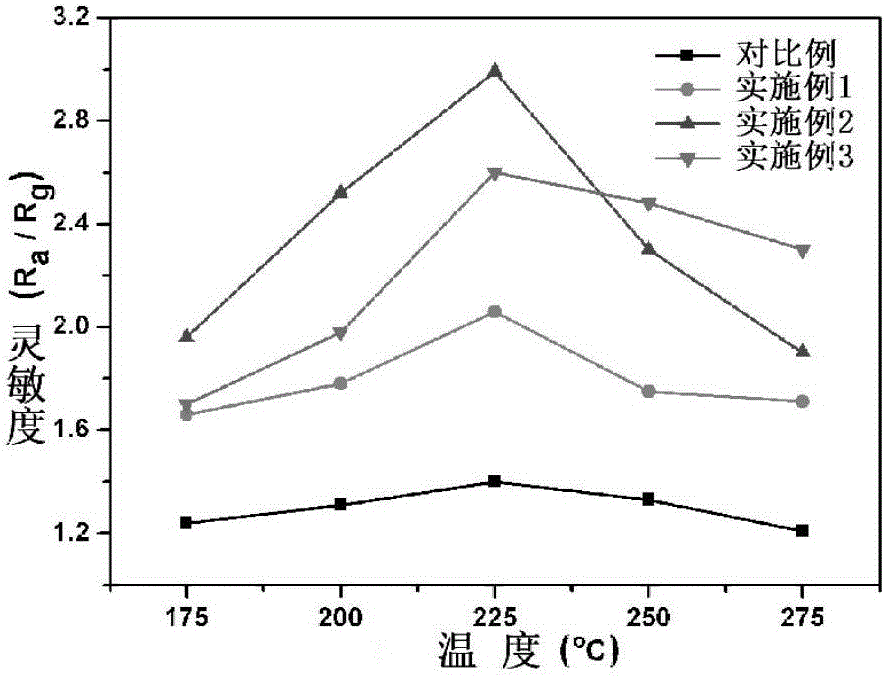

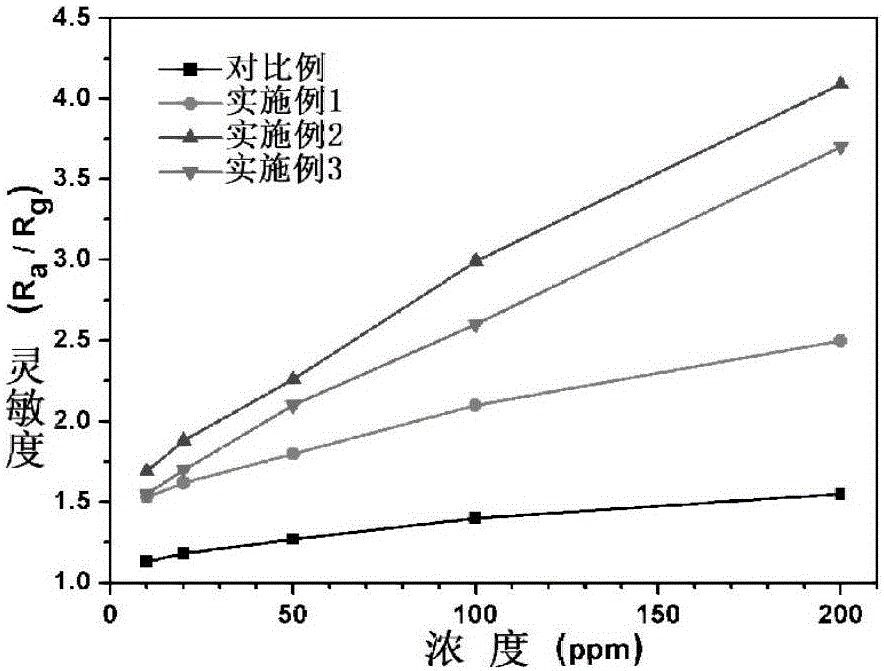

Embodiment 1

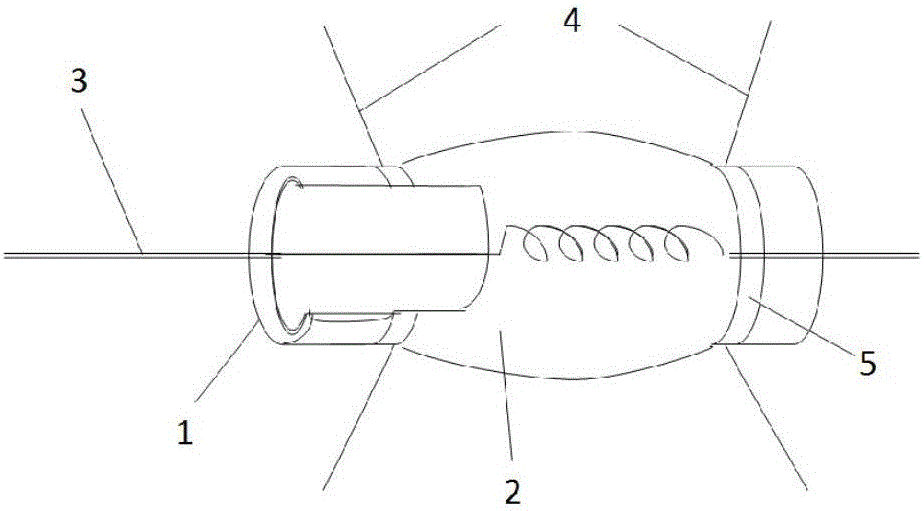

[0037] Pt-SnO with a mass ratio of element Pt / Sn in the reactant of 0.015:1 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0038] (1) First, 0.9gSnCl 2 2H 2 O, 2.94gNa 3 C 6 h 5 o 7 2H 2 O, 10mlNaOH (0.2M), and 10ml water were stirred for 10 minutes to form a homogeneous solution. 2 PtCl 6 Put into the above solution and continue to stir for 10 minutes, so that the mass ratio of element Pt and element Sn is 1.5wt%;

[0039] (2) Put the mixed solution of (1) into a 100ml polytetrafluoroethylene kettle, seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was collected by centrifugation with ethanol and deionized water, and then placed ...

Embodiment 2

[0043] Pt-SnO with a mass ratio of element Pt / Sn in the reactant of 0.030:1 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0044] (1) First, 0.9gSnCl 2 2H 2 O, 2.94gNa 3 C 6 h 5 o 7 2H 2 O, 10mlNaOH (0.2M), and 10ml water were stirred for 10 minutes to form a homogeneous solution. 2 PtCl 6 Put into the above solution and continue to stir for 10 minutes, so that the mass ratio of element Pt and element Sn is 3.0wt%;

[0045] (2) Put the mixed solution of (1) into a 100ml polytetrafluoroethylene kettle, seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was collected by centrifugation with ethanol and deionized water, and then placed ...

Embodiment 3

[0049] Pt-SnO with a mass ratio of element Pt / Sn in the reactant of 0.045:1 2 Oxide semiconductors are used as sensitive materials to make side-heated carbon monoxide sensors. The specific manufacturing process:

[0050] (1) First, 0.9gSnCl 2 2H 2 O, 2.94gNa 3 C 6 h 5 o 7 2H 2 O, 10mlNaOH (0.2M), and 10ml water were stirred for 10 minutes to form a homogeneous solution. 2 PtCl 6 Put into the above solution and continue to stir for 10 minutes, so that the mass ratio of element Pt and element Sn is 4.5wt%;

[0051] (2) Put the mixed solution of (1) into a 100ml polytetrafluoroethylene kettle, seal it, put it into a microwave hydrothermal system, and set the microwave parameters as follows: the maximum power is 300W, first heat it to 180°C for 10 minutes, and keep the temperature at 180°C for one hour. After the end, the temperature was naturally lowered to room temperature, and the sample was collected by centrifugation with ethanol and deionized water, and then placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com