Color filter having pressure sensing function and display screen

A color filter and pressure technology, applied in optics, nonlinear optics, data processing input/output process, etc., can solve the problems of increased area of frame wiring, lack of flexibility, high maintenance cost, etc., and achieve material stability Non-toxic and environmentally friendly, good material stability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

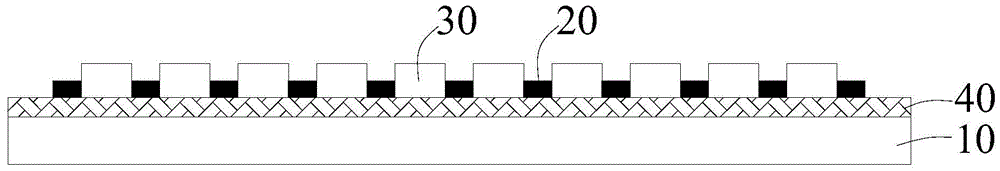

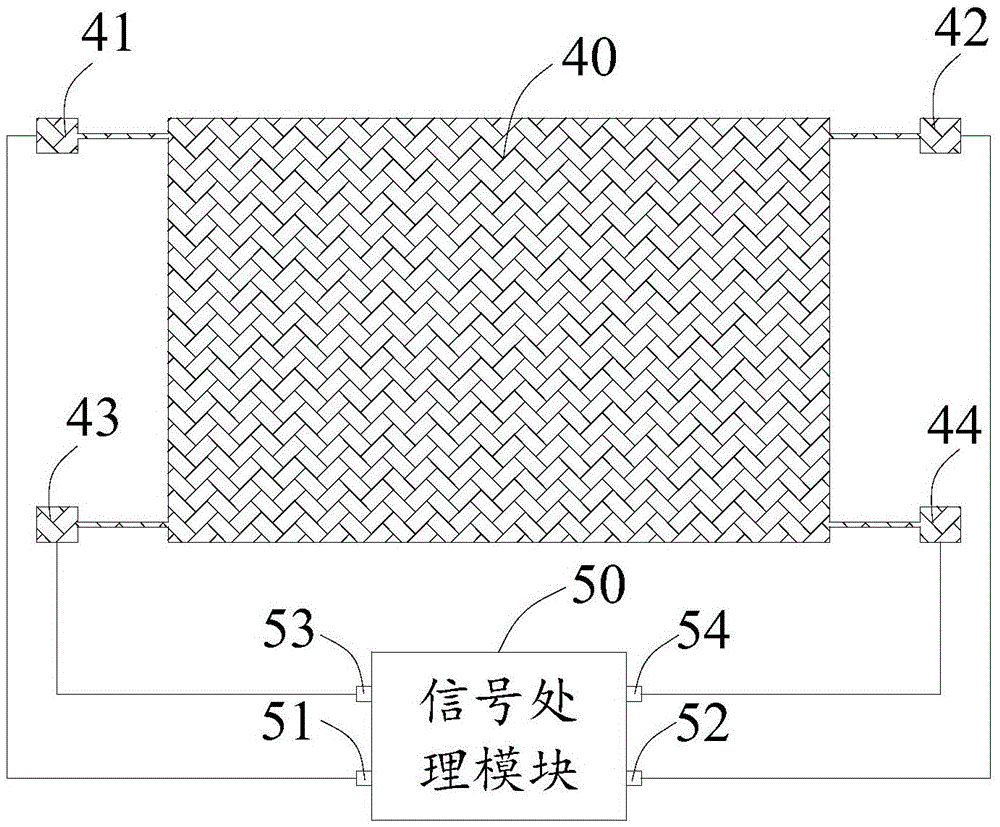

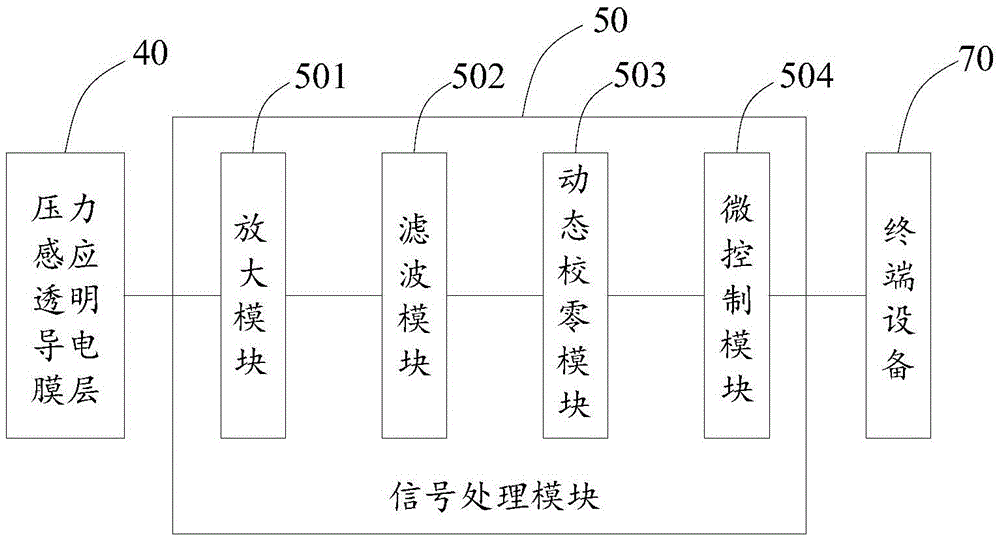

[0020] In order to better understand the purpose, structure and function of the present invention, the color filter and display screen with pressure sensing function of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] Piezoelectric film button is a technology developed in recent years. Its principle is to use the piezoelectric effect and rely on the movement of internal tiny charges to generate macroscopic voltage. The force acting on the piezoelectric film button causes the piezoelectric film to produce a small deformation and generate a charge corresponding to the strength. After processing and analysis, different functions can be controlled through different forces.

[0022] ZnO (zinc oxide) thin film is an optically transparent thin film. Pure ZnO and its doped thin film have excellent photoelectric properties and wide applications. Moreover, the raw materials are easy to obtain, cheap and have low toxic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com