Composite cathode material for lithium ion/sodium ion batteries and preparation method of composite anode material

A sodium-ion battery and negative electrode material technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as low electronic/ionic conductivity, cumbersome electrode preparation methods, and reduced rate performance and cycle performance of electrode materials. Achieve the effects of high reactive sites, broad industrial application prospects, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First place the conductive carbon paper in deionized water, alcohol, and ammonia water for 30 minutes, take it out and dry it, and use it as a working electrode, then weigh 4mmol of selenium dioxide, 12mmol of tin tetrachloride pentahydrate, and 250mmol of lactic acid in 1L of deionized water Stir for 10 minutes to make it all dissolve, then place the solution in the electrolytic cell, the working electrode has an area of 30cm 2 carbon paper, set the operating voltage to be -0.65V, and electrodeposit for 90 minutes to obtain the tin selenide / carbon paper composite material for lithium (sodium) ion batteries.

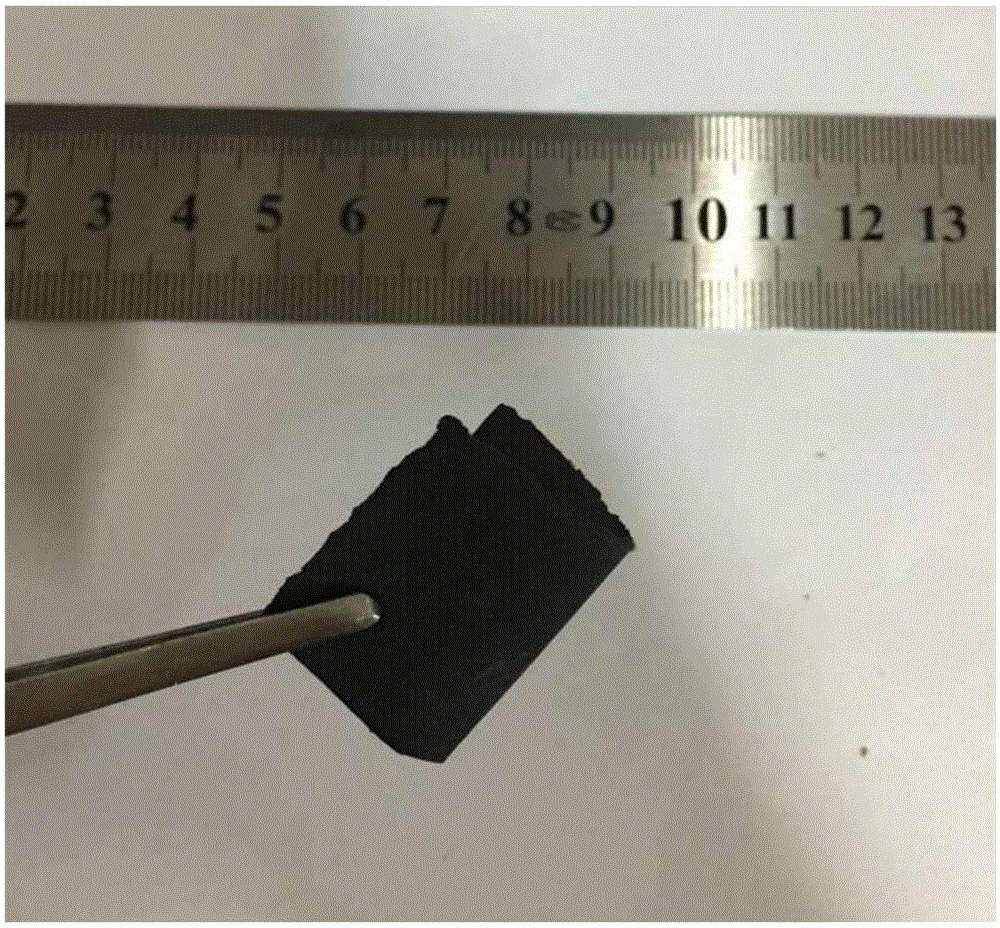

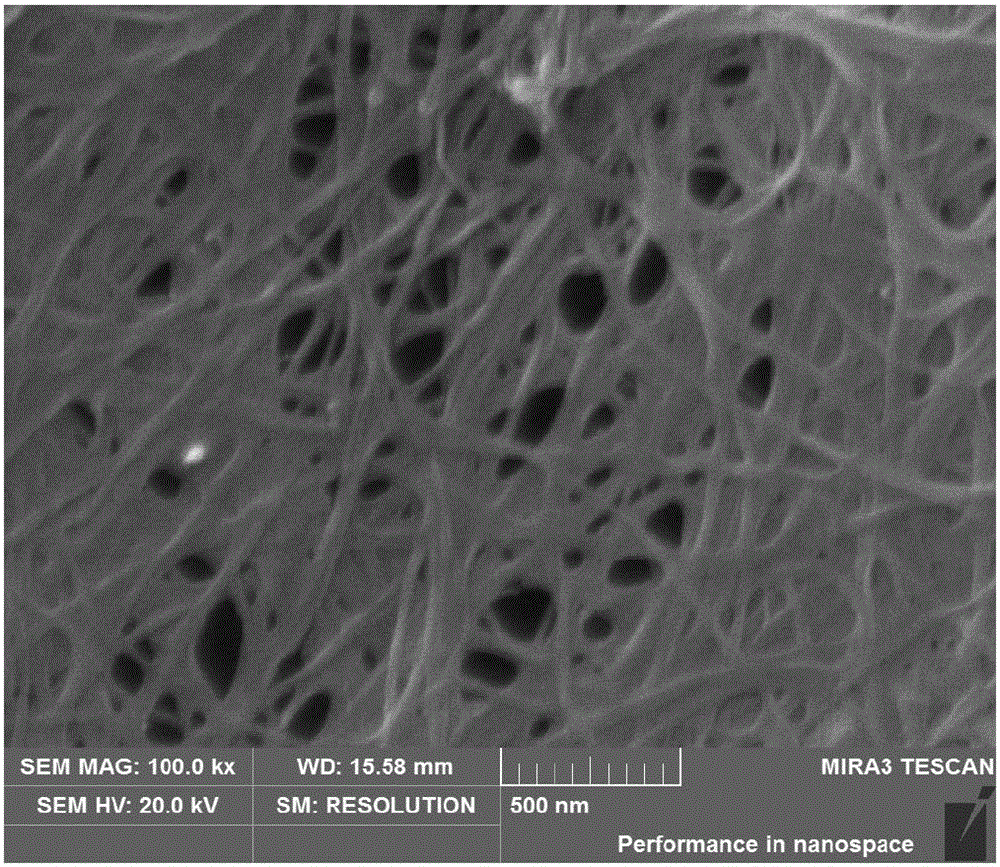

[0041] The lithium (sodium) ion battery composite negative electrode material prepared by this embodiment is assembled into a button battery with lithium (sodium) sheets, and its material characterization and electrochemical performance are as shown in the accompanying drawings:

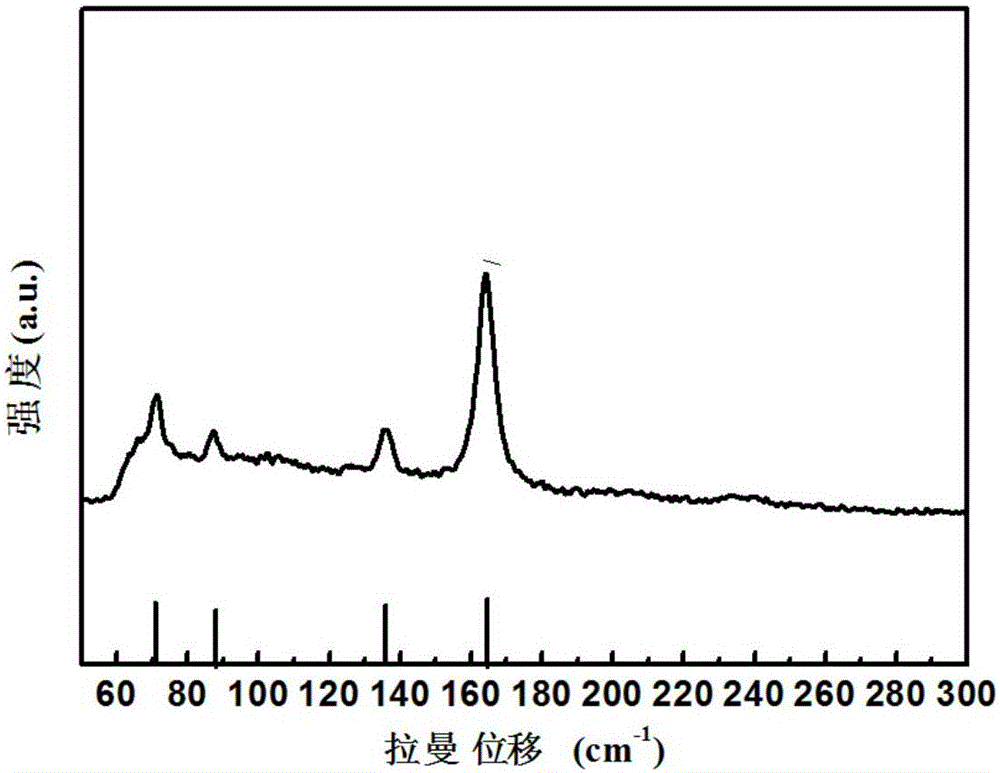

[0042] figure 1 It can be seen that the positions and relative intensities of the...

Embodiment 2

[0048]First place the conductive carbon paper in deionized water, alcohol, and ammonia water for 30 minutes, take it out and dry it, and use it as a working electrode, then weigh 3mmol of selenium dioxide, 10mmol of tin tetrachloride pentahydrate, and 250mmol of lactic acid in 1L of deionized water Stir for 10 minutes to make it all dissolve, then place the solution in the electrolytic cell, the working electrode has an area of 30cm 2 carbon paper, set the operating voltage to be -0.65V, and electrodeposit 90min to obtain the tin selenide / carbon paper composite material for lithium (sodium) ion batteries. The composite negative electrode material for lithium (sodium) ion batteries prepared in this embodiment and Lithium (sodium) sheets are assembled into button cells.

[0049] The composite material prepared in this example and the lithium (sodium) sheet are assembled into a button battery. Under a constant current discharge density of 200mA / g, the sodium storage capacity ca...

Embodiment 3

[0051] First place the conductive carbon paper in deionized water, alcohol, and ammonia water for 30 minutes, take it out and dry it, and use it as a working electrode, then weigh 5mmol of selenium dioxide, 16mmol of tin tetrachloride pentahydrate, and 250mmol of lactic acid in 1L of deionized water Stir for 10 minutes to make it all dissolve, then place the solution in the electrolytic cell, the working electrode has an area of 30cm 2 carbon paper, set the operating voltage to be -0.65V, and electrodeposit 90min to obtain the tin selenide / carbon paper composite material for lithium (sodium) ion batteries. The composite negative electrode material for lithium (sodium) ion batteries prepared in this embodiment and Lithium (sodium) sheets are assembled into button cells.

[0052] The composite material prepared in this example and the lithium (sodium) sheet are assembled into a button battery. Under a constant current discharge density of 200mA / g, the sodium storage capacity c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com