A fuel cell graphene gas diffusion membrane and preparation method thereof

A gas diffusion and fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., to achieve excellent anodic oxidation, reduce thickness and resistivity, and increase power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

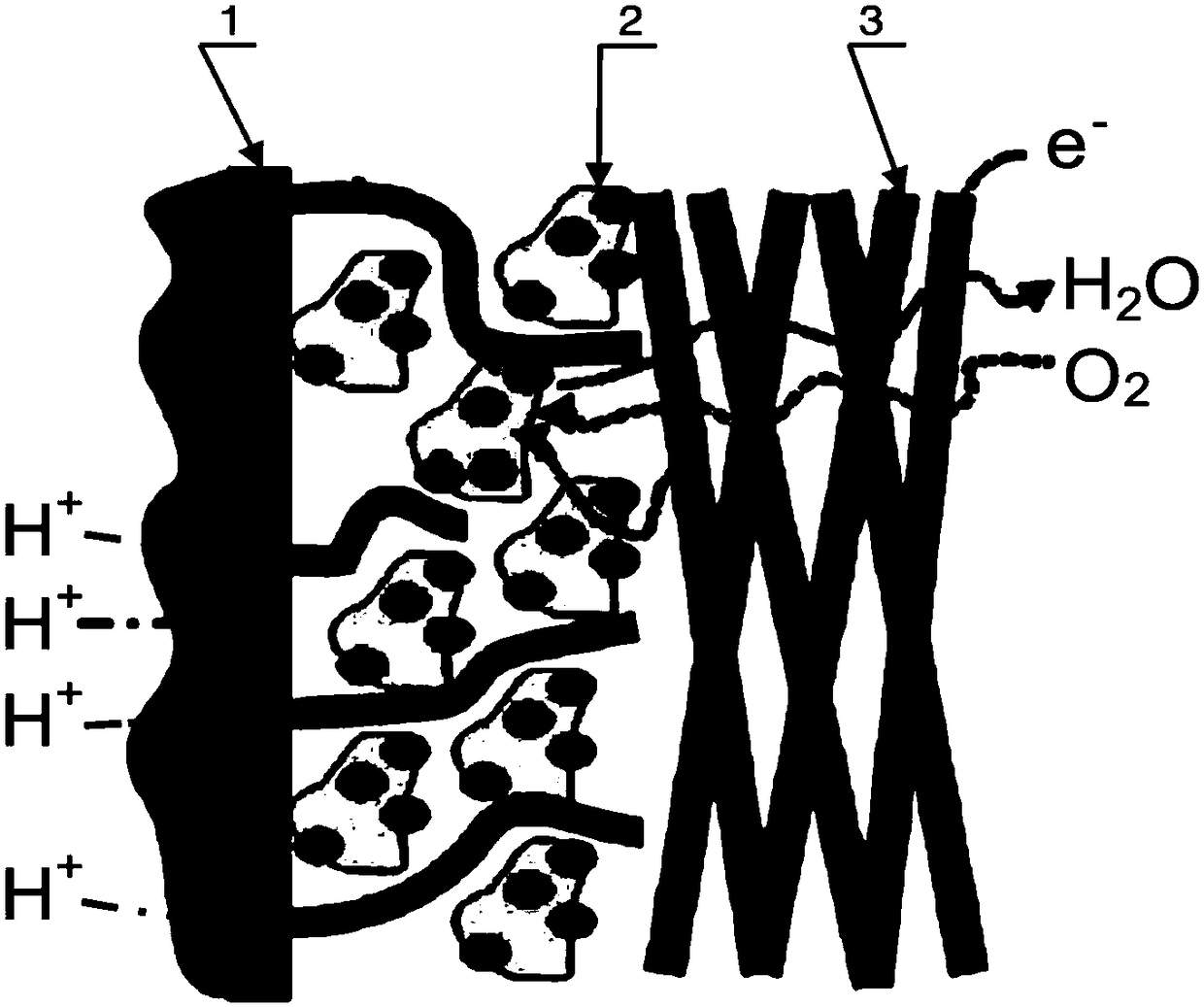

[0028] Such as figure 1 As shown, a fuel cell graphene gas diffusion membrane includes a proton conductive medium layer 1, a carbon-supported catalyst layer 2, and a carbon fiber conductive paper layer 3 in sequence from left to right.

[0029] a preparation process

[0030] (1) Making graphene composite carbon fiber

[0031] After mixing graphene oxide powder and deionized water at a weight ratio of 1.5:100, ultrasonic treatment was performed for 30 minutes to obtain a graphene solution;

[0032] The weight ratio of graphene solution to carbon fiber is 100:5. Put the graphene solution and carbon fiber into the cooking pot according to the weight ratio, cook at 100°C for 3 hours, then remove the water, and then dry and carbonize in the carbonization furnace at 400-600°C. Obtain graphene composite carbon fiber material;

[0033] (2) make graphene composite polyest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com