Lithium ion battery electrolyte solution and preparation method thereof, and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as flatulence of lithium titanate batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

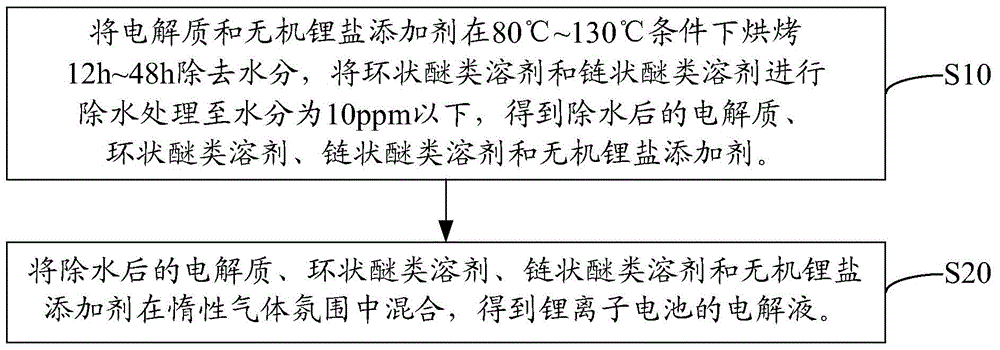

[0035] Such as figure 1 The preparation method of the electrolyte of above-mentioned lithium-ion battery shown, comprises the steps:

[0036] S10. Baking the electrolyte and the inorganic lithium salt additive at 80°C to 130°C for 12h to 48h to remove moisture, and performing dehydration treatment on the cyclic ether solvent and the chain ether solvent until the moisture content is below 10ppm to obtain dehydration The final electrolyte, cyclic ether solvent, chain ether solvent and inorganic lithium salt additive.

[0037] The electrolyte and the inorganic lithium salt additive can be placed in a vacuum vibration drying oven and baked at 80°C to 130°C for 12h to 48h to remove moisture.

[0038] The cyclic ether solvent and the chain ether solvent can be dewatered with molecular sieves until the water content is less than 10 ppm.

[0039] S20, mixing the dehydrated electrolyte, cyclic ether solvent, chain ether solvent and inorganic lithium salt additive in step S10 in an in...

Embodiment 1

[0045] LiODFB (99.95% pure) and LiNO 3 (purity is 99.95%) placed in a vacuum vibration drying oven at 130 ° C for 24 hours, cooled down. The solvents DME (purity: 99.99%) and DOL (purity: 99.99%) are treated with molecular sieves to reduce their water content to less than 10ppm, and LiODFB, DME, DOL, and LiNO are obtained after water removal. 3 .

[0046] LiODFB, DME, DOL and LiNO after water removal 3 Prepare the electrolyte in a glove box filled with argon: 1.0mol / LLiODFB+0.1mol / LLiNO 3 , DOL:DME=1:1 (volume ratio), the electrolyte solution of lithium-ion battery is obtained. The composition and basic performance test data of the electrolyte of the lithium-ion battery are shown in Table 1.

[0047] Composition and basic performance testing data of the electrolyte of the lithium ion battery of table 1 embodiment 1

[0048]

[0049] It can be seen from Table 1 that the room temperature ionic conductivity of the electrolyte of the lithium ion battery of Example 1 is rel...

Embodiment 2

[0051] LiTFSi (99.95% pure) and LiNO 3 (purity is 99.95%) placed in a vacuum vibration drying oven at 130 ° C for 24 hours, cooled down. The solvents DME (purity: 99.99%) and DOL (purity: 99.99%) are treated with molecular sieves to reduce their water content to less than 10ppm, and LiODFB, DME, DOL, and LiNO are obtained after water removal. 3 .

[0052] LiTFSi, DME, DOL and LiNO after water removal 3 Prepare the electrolyte in a glove box filled with argon: 1.0mol / LLiTFSi+0.1mol / LLiNO 3 , DOL:DME=1:1 (volume ratio), the electrolyte solution of lithium-ion battery is obtained. The composition and basic performance test data of the electrolyte of the lithium-ion battery are shown in Table 2.

[0053] The composition of the electrolyte of the lithium-ion battery of the embodiment 2 of table 2 and basic performance detection data

[0054]

[0055]

[0056] It can be seen from Table 2 that the room temperature ionic conductivity of the electrolyte of the lithium ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com