Motor controller

A technology of motor controller and control board, which is applied in the direction of motor control, control system, and mechanical energy control, etc. It can solve the problems of pin burnout and reduce the service life of the motor controller, so as to reduce the length, avoid burnout phenomenon, and facilitate The effect of air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

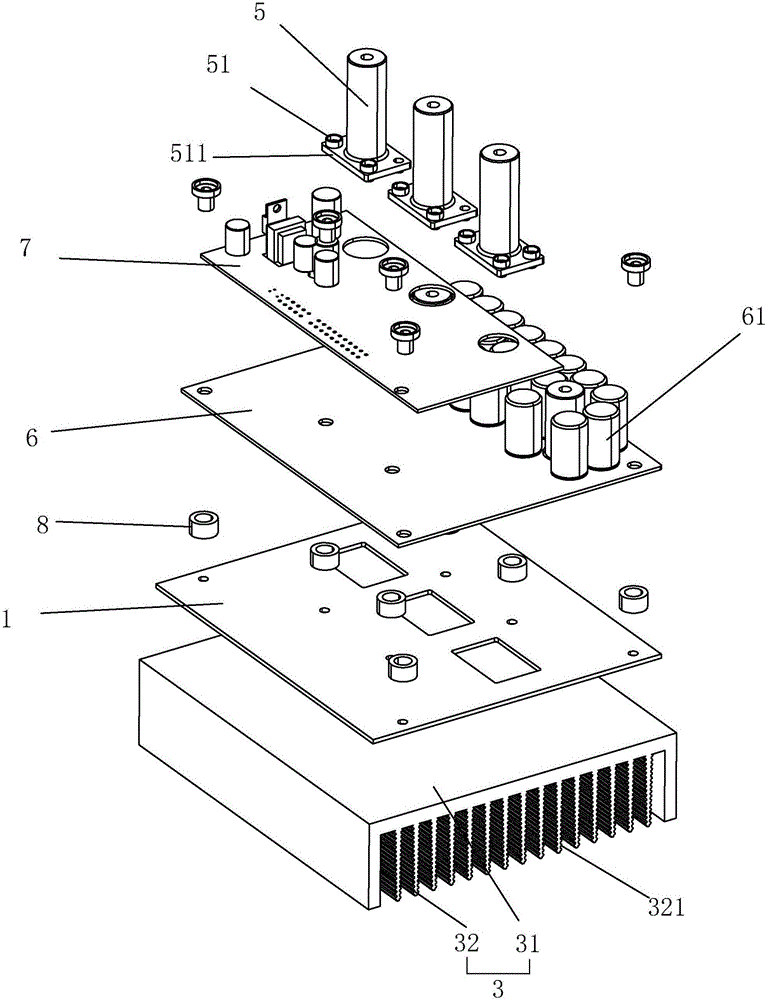

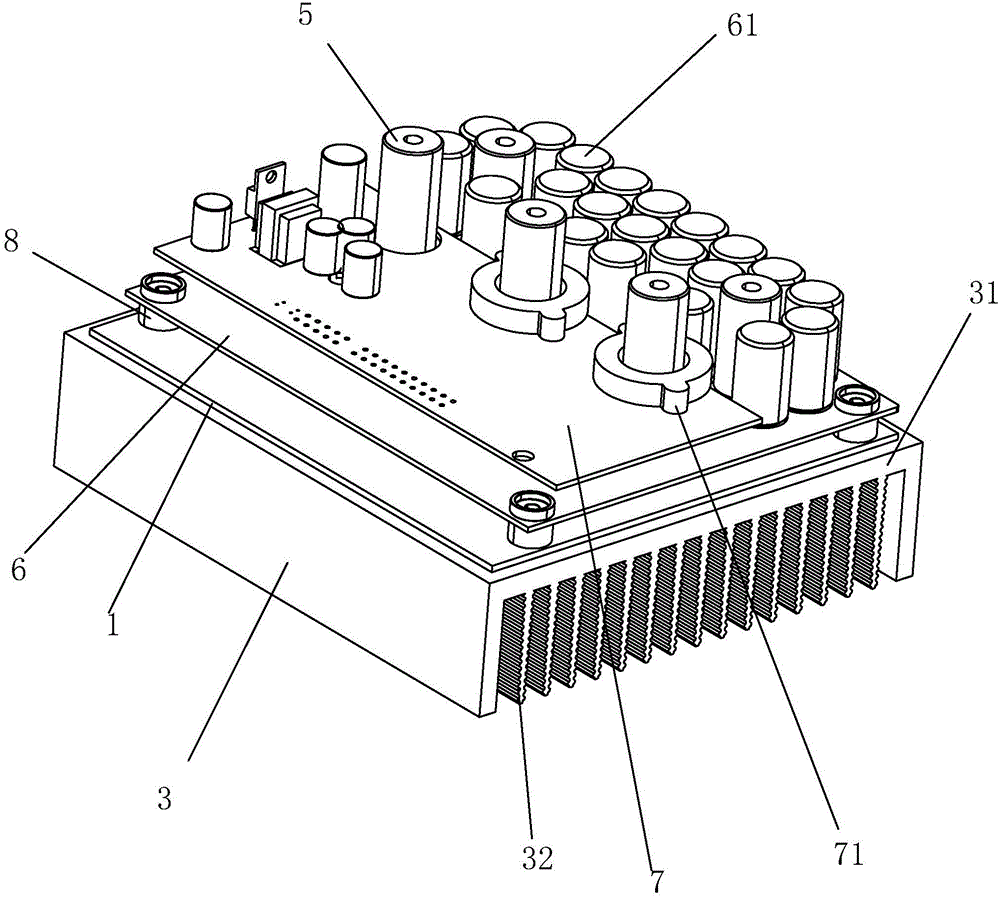

[0038] The following is attached Figure 1-7 The present invention is described in further detail.

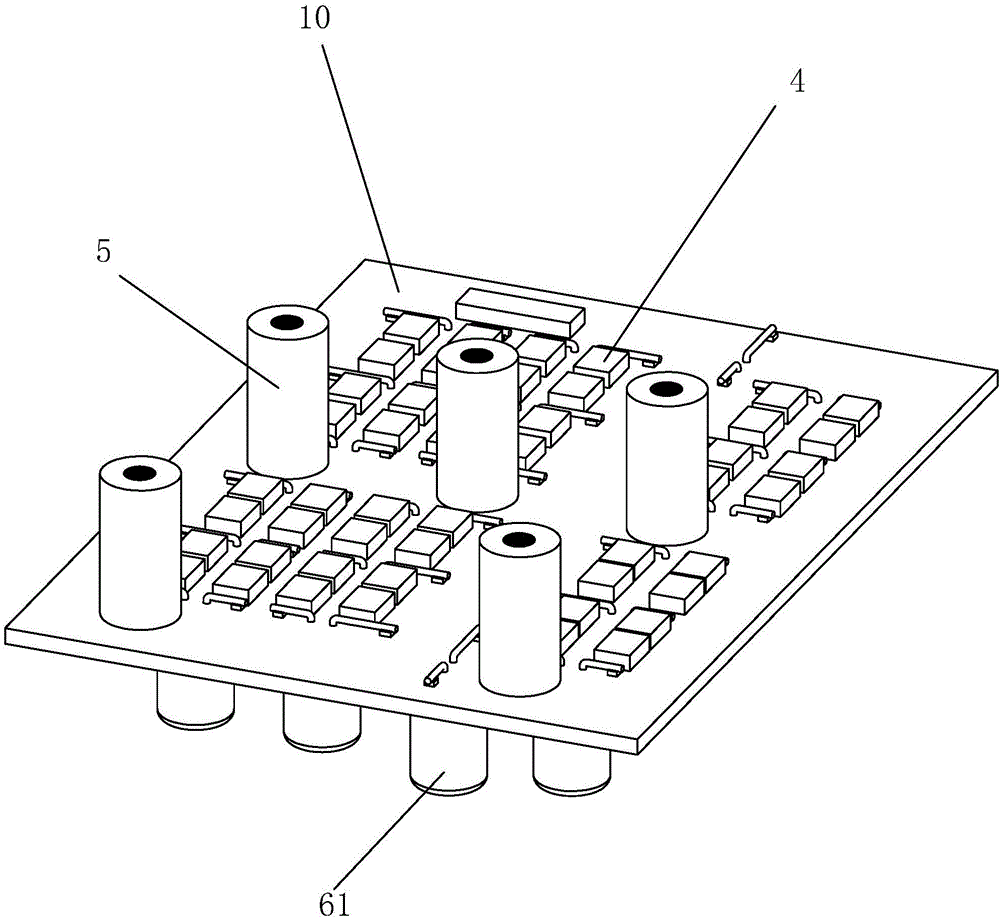

[0039] A motor controller, referring to figure 2 , including a housing, a power board 1 is provided in the housing, and the power board 1 is used to install the MOS tube 4 and the phase line connecting column 5, and a capacitor board 6 is arranged above the power board 1, and the capacitor board 6 is used to install a capacitor 61 , a control board 7 is installed above the capacitor board 6, and the control board 7 is used to install control components to control the MOS tube 4 and the capacitor 61 tube, wherein the capacitor board 6 and the control board 7 are all made of PCB materials, and the power There is a conductive post 8 between the board 1 and the control board 7. The conductive post 8 is made of copper material. The conductive post 8 can connect the power board 1 and the capacitor board 6 to realize the connection between the two. The conductive post 8 is hollow. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com