A kind of fragrant shredded pleurotus eryngii and preparation method thereof

A technology of king oyster mushroom and fragrant silk, which is applied in the directions of edible oil/fat, function of food ingredients, and vegetable protein processing, etc., can solve the problems of high water holding capacity of materials, long time consumption, and low specific volume value of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

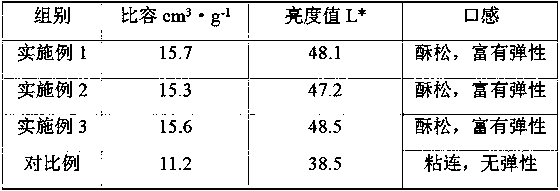

Examples

Embodiment 1

[0028] Pleurotus eryngii processing by-products are used as raw materials, dried at 45°C, superfinely pulverized and passed through 240 meshes to obtain pleurotus eryngii superfine powder. 24°C palm oil is liquefied, and the obtained pleurotus eryngii superfine powder is added at 24°C. The mass ratio of palm oil to Pleurotus eryngii superfine powder is 45:22, then heated to 50°C, stirred evenly with a liquid mixing mixer at a constant temperature, and maintained at this temperature, injected into the high-pressure homogenizer for high-pressure homogenization , The pressure is 50MPa, and the Pleurotus eryngii cream is prepared for use;

[0029] A preparation method of Pleurotus eryngii fragrant shreds comprises the following steps:

[0030] 1) Rehydration: soak 12kg soybean silk protein in 60℃ water for 50min;

[0031] 2) Wire drawing dehydration: the soybean wire drawing protein after step 1) rehydration is broken once with a three-roller loosening machine, and the broken soybean wi...

Embodiment 2

[0035] Pleurotus eryngii processing by-products are used as raw materials. After drying at 50°C, superfine pulverization treatment and 250 meshes are used to obtain pleurotus eryngii superfine powder. The 24°C palm oil is liquefied and the obtained pleurotus eryngii superfine powder is added at 24°C. The mass ratio of palm oil to Pleurotus eryngii superfine powder is 25:14, and then heated to 60℃, at a constant temperature, stir evenly with a liquid mixing mixer, and maintain the temperature, inject into the high-pressure homogenizer for high-pressure homogenization , The pressure is 55MPa, and the Pleurotus eryngii cream is prepared for use;

[0036] A preparation method of Pleurotus eryngii fragrant shreds comprises the following steps:

[0037] 1) Rehydration: soak 11kg soybean silk protein in 65℃ water for 40min;

[0038] 2) Wire drawing dehydration: the soybean wire drawing protein after step 1) rehydration is broken once with a three-roller loosening machine, and the broken so...

Embodiment 3

[0042] Pleurotus eryngii processing by-products are used as raw materials. After drying at 48°C, superfine pulverization treatment and 245 meshes are used to obtain pleurotus eryngii superfine powder. The 24°C palm oil is liquefied and the obtained pleurotus eryngii superfine powder is added at 24° The mass ratio of palm oil to Pleurotus eryngii superfine powder is 12:7, and then heated to 55°C, at a constant temperature, stir evenly with a liquid mixing mixer, and maintain the temperature, and inject it into a high-pressure homogenizer for high-pressure homogenization , The pressure is 60MPa, and the Pleurotus eryngii cream is prepared for use;

[0043] A preparation method of Pleurotus eryngii shreds includes the following steps:

[0044] 1) Rehydration: Soak 10kg soybean silk protein in 65℃ water for 40min;

[0045] 2) Wire drawing dehydration: the soybean wire drawing protein after rehydration in step 1) is broken once with a three-roller loosening machine, and the broken soybea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com