A preparation method of nanocrystalline cellulose magnetic particles adsorbing heavy metal ions

A technology for nanocrystalline cellulose and heavy metal adsorption, which is applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of heavy metal ions exceeding the standard, achieve good effect, low cost, and adsorption The effect of large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

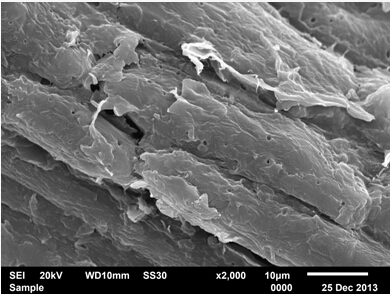

Image

Examples

Embodiment 1

[0021] A preparation method for nanocrystalline cellulose magnetic particles adsorbing heavy metal ions, comprising the following steps:

[0022] The preparation method of microcrystalline cellulose is to use sycamore sawdust as raw material, cook with distilled water at 95°C for 2 hours, then dry at 120°C for 10 hours, pulverize through a 200-mesh sieve, wash twice, and then dry at 140°C to obtain lignocellulose. Then mix 1g lignocellulose with a solid-liquid ratio: 35mL of 1.2mol / L hydrochloric acid, heat up to 60°C for 1h, and then filter with suction at an ultrasonic frequency of 55KHz. , the obtained filter residue is dried to a water content of 5%, and then discharged and pulverized to obtain microcrystalline cellulose;

[0023] The preparation method of nanocrystalline cellulose is to add microcrystalline cellulose and strongly acidic cation exchange resin to 1000mL deionized water at a mass ratio of 1:15, stir at 65°C, and ultrasonically treat for 1h at an ultrasonic f...

Embodiment 2

[0026] A preparation method for nanocrystalline cellulose magnetic particles adsorbing heavy metal ions, comprising the following steps:

[0027] The preparation method of microcrystalline cellulose is to use sycamore sawdust as raw material, cook it with distilled water at 98°C for 3 hours, then dry it at 135°C for 11 hours, crush it through a 250 mesh sieve, wash it three times, and dry it at 150°C to obtain lignocellulose. Then mix 1g lignocellulose with a solid-liquid ratio: 40mL of 1.3mol / L hydrochloric acid, heat up to 65°C and ultrasonically treat for 1.2h, then filter with suction, wash the filter residue to neutral, soak it with 95wt% ethanol for 2.5h, and then filter to obtain The filter residue was dried to a water content of 8%, and then discharged and pulverized to obtain microcrystalline cellulose;

[0028]The preparation method of nanocrystalline cellulose is to add microcrystalline cellulose and strongly acidic cation exchange resin into 1000mL deionized water ...

Embodiment 3

[0031] A preparation method for nanocrystalline cellulose magnetic particles adsorbing heavy metal ions, comprising the following steps:

[0032] The preparation method of microcrystalline cellulose is to use sycamore wood chips or willow wood chips as raw materials, cook them with distilled water at 100°C for 4 hours, then dry them at 155°C for 12 hours, crush them through a 300-mesh sieve, wash them three times, and dry them at 160°C to obtain woody cellulose. Cellulose, then mix 1g lignocellulose with 50mL of 1.5mol / L hydrochloric acid at a material-to-liquid ratio, raise the temperature to 70°C and ultrasonically treat for 1.5h, then filter with suction, wash the filter residue until it is neutral, soak it in 98wt% ethanol for 3h, and then filter , the obtained filter residue is dried to a water content of 10%, and then discharged and pulverized to obtain microcrystalline cellulose;

[0033] The preparation method of nanocrystalline cellulose is to add microcrystalline cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com