Method for preparing graphite phase carbon nitride nanosheet/titania nanotube array photocatalysis material

A technology of graphitic carbon nitride and nanotube arrays, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low catalytic efficiency of visible light, and achieve high-efficiency degradation and excellent visible light catalysis performance, ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment 1: This embodiment is the simple preparation of graphite phase carbon nitride nanosheet / titanium dioxide nanotube array photocatalytic material, and the specific steps are as follows:

[0022] 1) Put 10g of melamine into a crucible with a lid, and place it in a muffle furnace at a temperature of 450-550°C for 2 to 4 hours, and a heating rate of 10°C / min. After the calcination is completed, it is naturally cooled to room temperature, and the obtained sample is ground into powder to prepare bulk graphite phase carbon nitride;

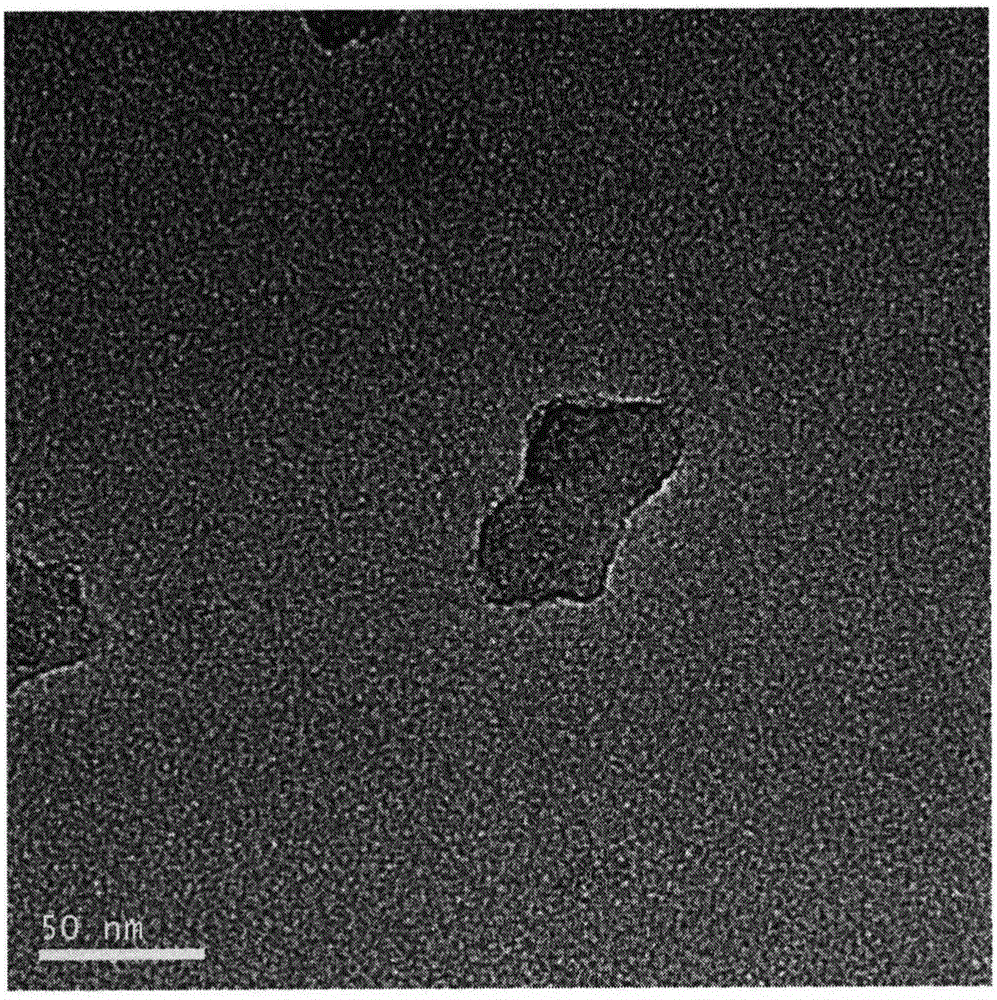

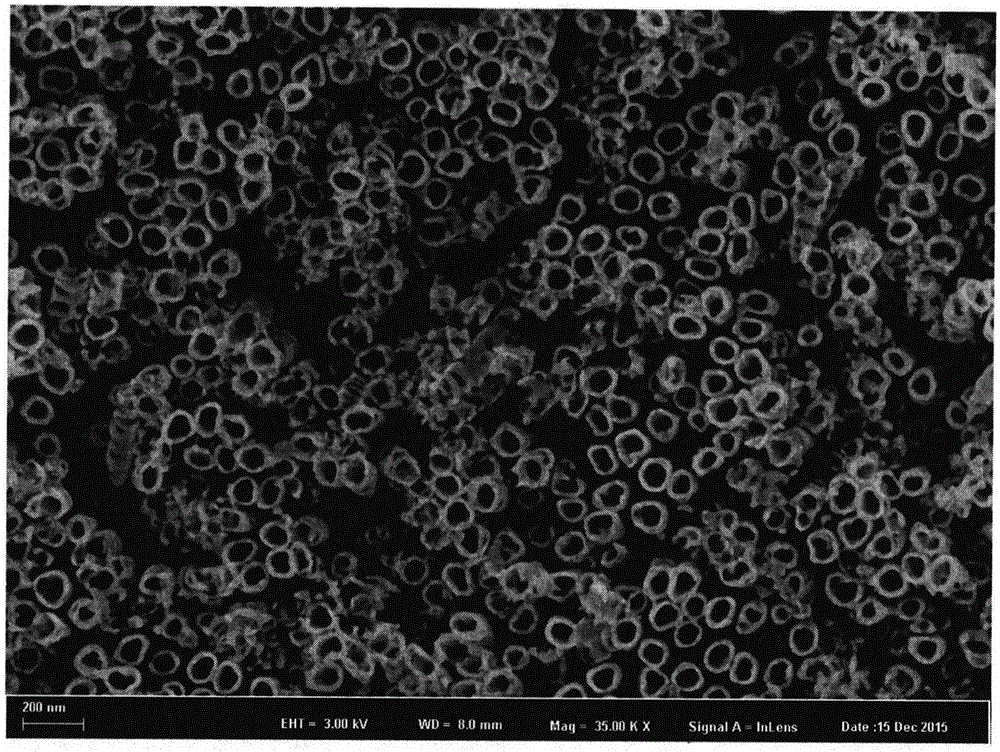

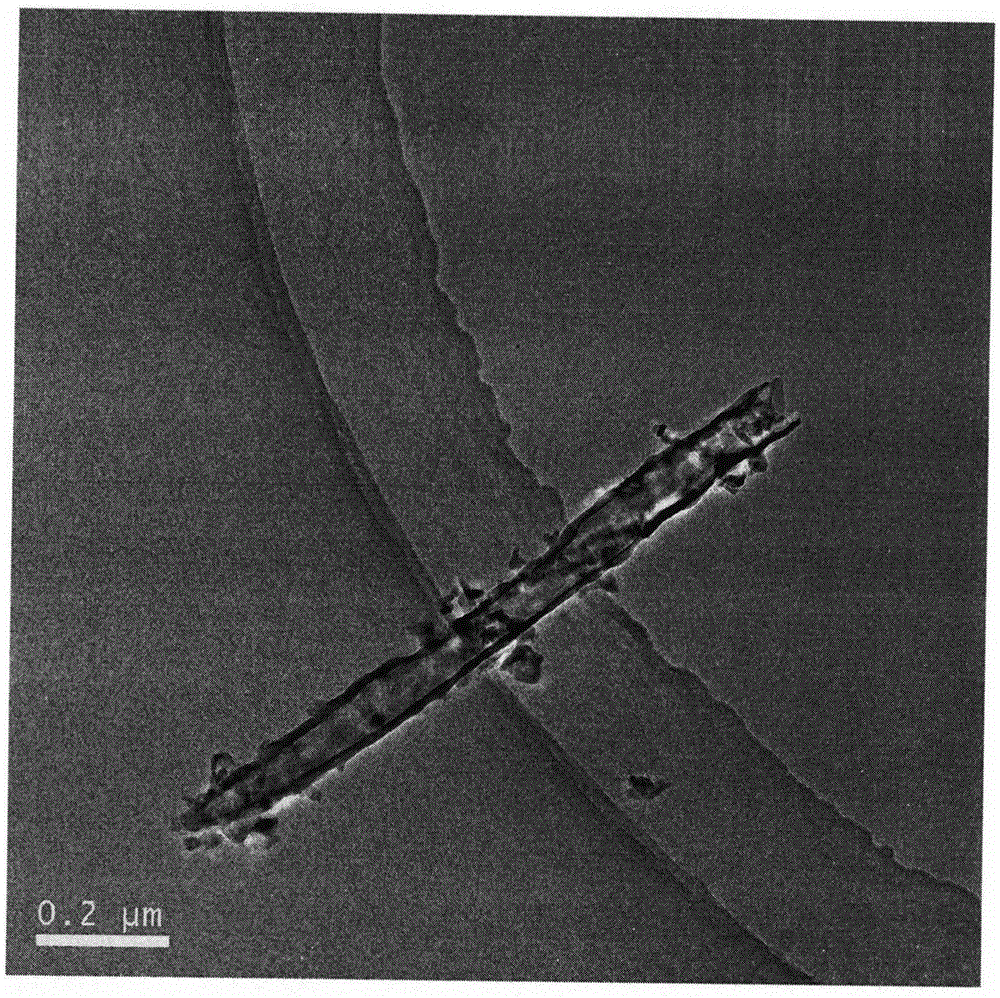

[0023] 2) Take 2g of the bulk graphite phase carbon nitride prepared in step 1 and add it to 30-50ml concentrated sulfuric acid and continue stirring for 8h. Then the mixture was slowly poured into 200ml deionized water, ultrasonically stripped for 6-10h, and then centrifuged at 1000rpm, the precipitate was washed repeatedly with deionized water for 5-15 times to obtain colloidal graphite phase carbon nitride nanosheets, and then Th...

specific Embodiment 2

[0027] Specific embodiment two: This embodiment is different from the specific embodiment one in that the calcination temperature in step one is 520°C. Others are the same as the first embodiment.

specific Embodiment 3

[0028] Specific embodiment three: This embodiment is different from specific embodiment one in that the number of rinses with deionized water in step two is 10 times. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com