Hydraulic auxiliary driving system with energy recovery and speed slowing functions and method thereof

A technology of auxiliary drive and energy recovery, which is applied in the arrangement of multiple prime movers and brakes of the pneumatic power plant and general power plant, and can solve the problem of increasing the cost of car purchase and the difficulty of layout, and the high price of the hydraulic retarder. problems, to achieve the effect of reducing the probability of mechanical brake failure, realizing miniaturization design, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

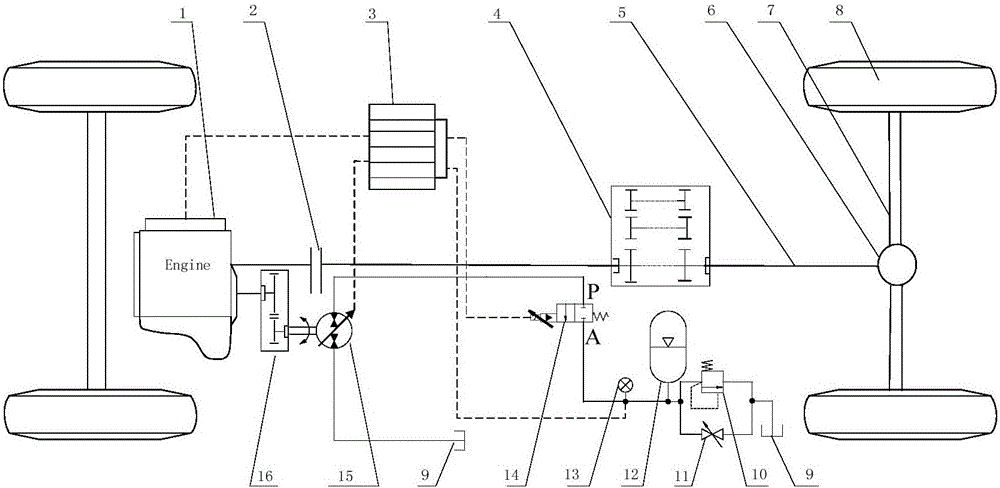

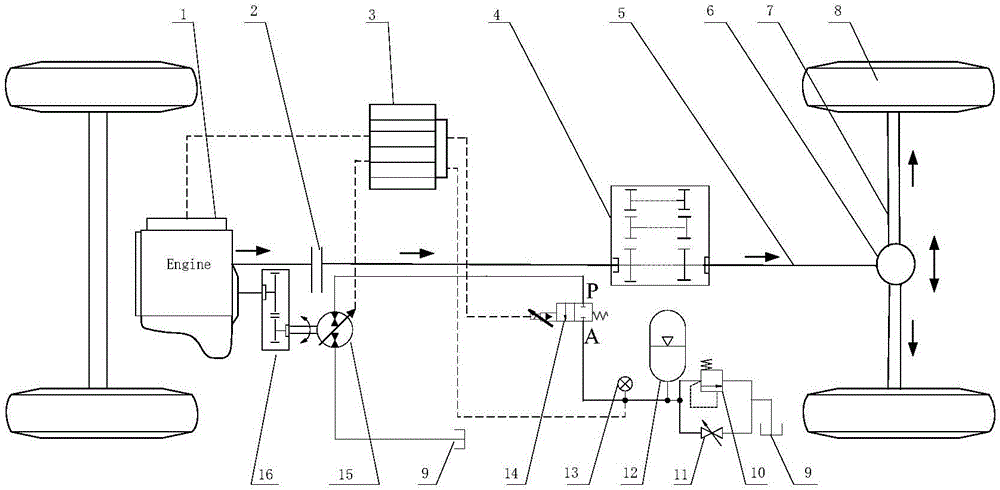

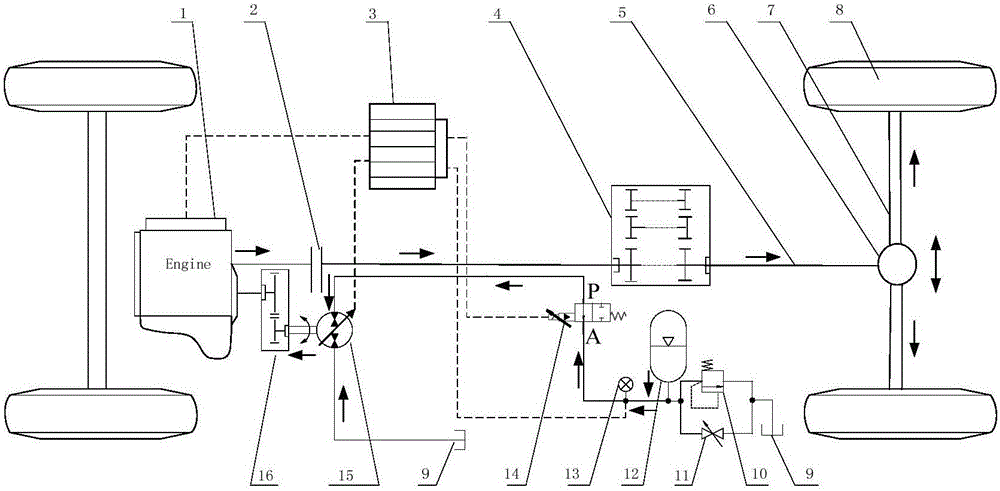

[0051] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0052] refer to figure 1 , the hydraulic auxiliary drive system capable of energy recovery in the present invention includes a power take-off 16, a hydraulic pump / motor 15, an electro-hydraulic proportional valve 14, a pressure indicator 13, an accumulator 12, an overflow valve 10, and a discharge valve 11. Controller 3, hydraulic oil tank 9.

[0053] refer to figure 1 , one end of the power take-off 16 is connected with the output shaft of the engine 1 driving accessories, and is connected by a spline sleeve, and the other end is connected with the rotor shaft of the hydraulic pump / motor 15 fixedly installed on the vehicle frame, and is connected by a spline sleeve or Flange or short universal joint connection, so as to transmit the power of the engine 1 to the hydraulic pump / motor 15 and drive its working pump oil.

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com