Preparation method and dispersing method of nano CaCO3/SiO2 composite particle

A composite particle and nanotechnology, which is applied in the fields of calcium/strontium/barium compounds, calcium carbonate/strontium/barium, chemical instruments and methods, etc. Easy to disperse, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

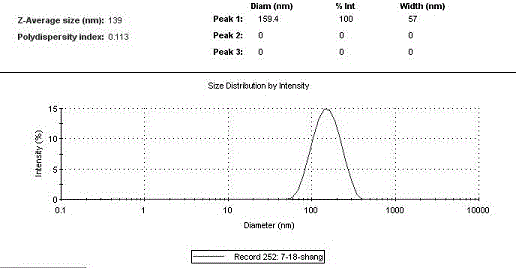

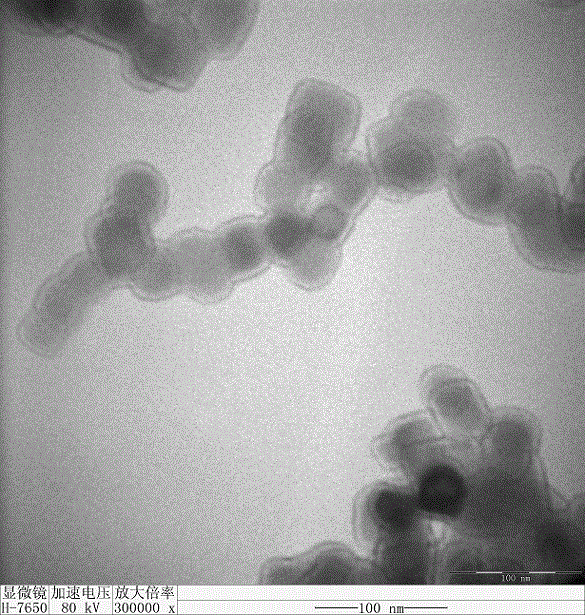

Image

Examples

Embodiment 1

[0028] (1) Put 27.97g of quicklime into 280g of water at 80°C, and digest it for 2h with a dispersing disc at 1000rpm. Pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, add water to form a suspension with a mass fraction of 12wt%, age for 24h, and set aside;

[0029] (2) Disperse the calcium hydroxide suspension in step (1) with a dispersing disc at 1000rpm in line-cutting mode, add 0.6% sulfuric acid solution, control the carbonization temperature at 15°C, and inject CO from the bottom 2 / N 2 Mixed gas (60 / 120m 3 h -1 m -3 Suspension), for carbonization, 5min after the start of the carbonization reaction, add 0.5% PEG-600 and 5% silica sol solution (the SiO 2 The average particle size is 5-10nm), and finally carbonized to pH=6.5 to obtain the composite particle slurry;

[0030] (3) Heat the slurry water bath in step (2) to 80°C, and pass a small amount of CO in the process 2 / N 2 The mixed gas keeps the pH=7.0, completely carbonizes the c...

Embodiment 2

[0034] (1) Put 24.76g of quicklime into 280g of water at 70°C and digest it for 3h with a dispersing disc at 1000rpm. The obtained calcium hydroxide suspension is passed through a 200-mesh standard sieve, then water is added to form a suspension with a mass fraction of 11wt%, aged for 20 hours, and set aside;

[0035] (2) Disperse the calcium hydroxide suspension in step (1) with a dispersing disc at 1000rpm, add 0.9% sodium hexametaphosphate, control the carbonization temperature at 20°C, and inject CO from the bottom 2 / N 2 Mixed gas (60 / 120m 3 h -1 m -3 Suspension) for carbonization, 10min after the start of the carbonization reaction, add 1.0% PEG-800 and 10% silica sol solution (the SiO 2 The average particle size is 5-10nm), and finally carbonized to pH=6.8 to obtain the composite particle slurry;

[0036] (3) Heat the slurry water bath in step (2) to 90°C, and pass a small amount of CO in the process 2 / N 2 The mixed gas keeps the pH=7.0, completely carbonizes th...

Embodiment 3

[0040] (1) Put 22.95g of quicklime into 280g of water at 70°C and digest it for 2h with a dispersing disc at 1000rpm. Pass the obtained calcium hydroxide suspension through a 200-mesh standard sieve, add water to form a suspension with a mass fraction of 10wt%, age for 22 hours, and set aside;

[0041] (2) Disperse the calcium hydroxide suspension in step (1) with a dispersing disc at 1000rpm, add 1.0% sodium silicate nonahydrate, control the carbonization temperature at 18°C, and inject CO from the bottom 2 / N 2 Mixed gas (60 / 120m 3 h -1 m -3 Suspension), for carbonization, 8 minutes after the start of the carbonization reaction, add 1.3% PEG-800 and 15% silica sol solution (the SiO 2 The average particle size is 5-10nm), and finally carbonized to pH=6.8 to obtain the composite particle slurry;

[0042] (3) Heat the slurry water bath in step (2) to 85°C, and pass a small amount of CO in the process 2 / N 2 The mixed gas keeps the pH=7.0, completely carbonizes the coated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com