Preparation method of stannous oxide particles with photocatalytic activity

A technology of photocatalytic activity and stannous oxide, applied in tin oxide, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low purity of production process and small specific surface area, and achieve environmentally friendly raw materials and large specific area Surface area, the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 1g of SnCl to the beaker 2 ·H 2 0 and 30 mL ethanol;

[0033] (2) Pour 0.050g of surfactant (sodium hexadecylbenzenesulfonate) and 30mL of deionized water into a beaker to dissolve;

[0034] (3) Add the solution of step (1) and step (2) into a hydrothermal reaction kettle with a volume of 100mL, mix evenly, and ultrasonicate for 10 minutes;

[0035] (4) Add 15mL of 4mol·L -1 The strong alkali (NaOH) solution is used as the precipitant, the temperature of the hydrothermal reaction kettle is set at 120°C, and the reaction time is 24h;

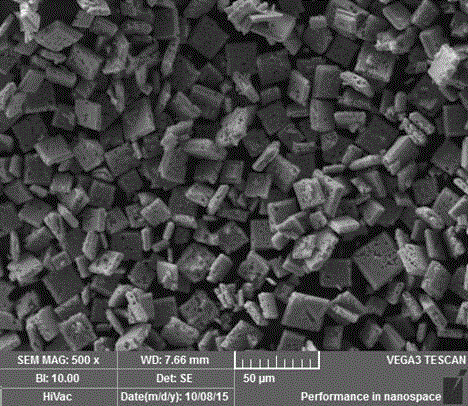

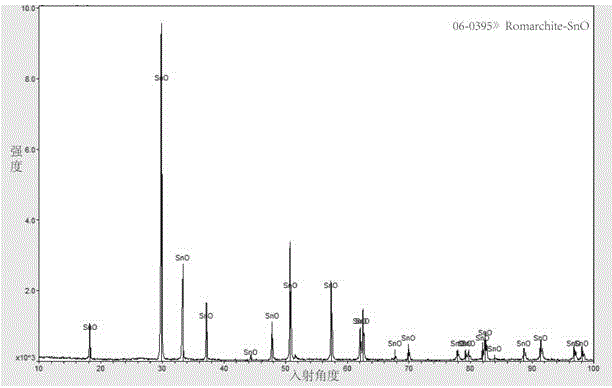

[0036] (5) After taking out the precipitate obtained in step (4), wash it three times with deionized water and ethanol respectively, and dry the obtained product at 60°C for 12 hours to obtain square sheet porous stannous oxide particles; Heat treatment at 140°C for 2 hours in an air drying oven to obtain stannous oxide particles with photocatalytic activity. From seeing figure 1 It can be clearly seen that the material has a...

Embodiment 2

[0039] (1) Add 4g of SnCl to the beaker 2 ·H 2 0 and 30 mL ethanol;

[0040] (2) Pour 0.100g of surfactant (potassium dodecylbenzoate) and 30mL of deionized water into a beaker to dissolve;

[0041] (3) Add the solution of step (1) and step (2) into a hydrothermal reaction kettle with a volume of 100mL, mix evenly, and ultrasonicate for 20 minutes;

[0042] (4) Add 15mL of 6mol·L -1 The strong alkali (KOH) solution is used as the precipitant, and the temperature of the hydrothermal reaction kettle is set at 180°C, and the reaction time is 4h;

[0043](5) After taking out the precipitate obtained in step (4), wash it with deionized water and ethanol for 5 times respectively, and dry the obtained product at 90°C for 12 hours to obtain square sheet porous stannous oxide particles. Heat treatment at 180°C for 2 hours in an air drying oven to obtain stannous oxide particles with photocatalytic activity. From seeing Figure 4 It can be clearly seen that the material has a squa...

Embodiment 3

[0046] (1) Add 2g of SnCl to the beaker 2 ·H 2 0 and 30 mL ethanol;

[0047] (2) Pour 0.060g of surfactant (potassium laurate) and 30mL of deionized water into a beaker to dissolve;

[0048] (3) Add the solution of step (1) and step (2) into a hydrothermal reaction kettle with a volume of 100mL, mix evenly, and sonicate for 15 minutes;

[0049] (4) Add 15mL of 5mol·L -1 The strong alkali (NaOH) solution was used as the precipitant, and the temperature of the hydrothermal reaction kettle was set at 130°C, and the reaction time was 8h;

[0050] (5) Take out the precipitate obtained in step (4) and wash it four times with deionized water and ethanol respectively, and dry the obtained product at 70°C for 12 hours to obtain square sheet porous stannous oxide particles. Heat treatment at 160°C for 2 hours in an air drying oven to obtain stannous oxide particles with photocatalytic activity.

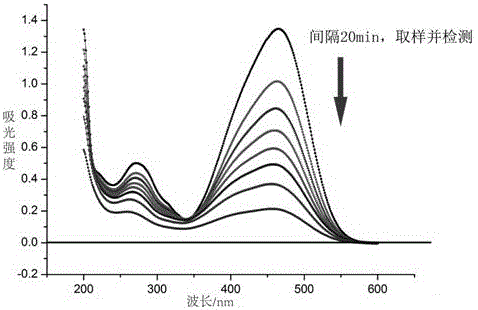

[0051] (6) At room temperature of 25°C, take 0.05 g of the photocatalytically active s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com