A high-hardness two-component waterborne polyurethane floor coating

A water-based polyurethane and floor coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor weather resistance, easy aging, and insufficient hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

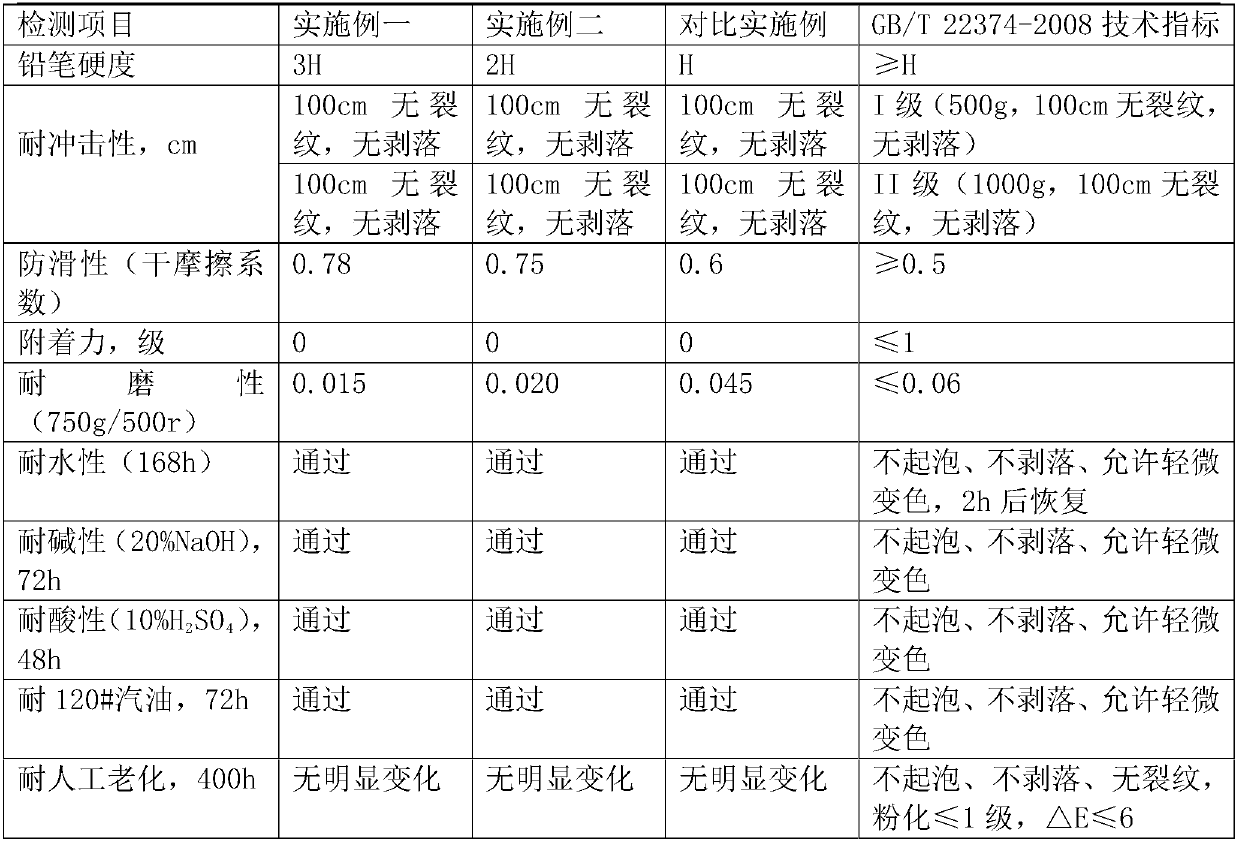

Examples

Embodiment 1

[0026] A high-hardness two-component waterborne polyurethane floor coating consisting of two components, A and B, wherein the A component is a water-based aliphatic isocyanate with a solid content of 100%; the B component is composed of the following components, the quality of each component The parts are: deionized water 11.1%; modified polymer dispersant 1%. It is a product produced by Kyoeisha Chemical Co., Ltd., and its brand is FLOWLEN G-700AMP, which is a modified polymer containing hydroxyl 2 -Amino-2-methyl-1-propanol salt, the solid content of which is 40-50% by mass; the multifunctional amine additive 0.5%, is a product produced by the Dow Company of the United States, and its brand is AMP-95; Ionic wetting agent 0.3%, produced by Clariant, its brand is LCN 070, it is an alkyl polyoxyethylene ether, its effective substance content is 100%, HLB value is 13; titanium dioxide 10% , Is a product produced by DuPont of the United States, its brand is R902, which is a rutile...

Embodiment 2

[0035] A high-hardness two-component waterborne polyurethane floor coating consisting of two components, A and B, wherein the A component is a water-based aliphatic isocyanate with a solid content of 100%; the B component is composed of the following components, the quality of each component The parts are: deionized water 11.1%; modified polymer dispersant 1%. It is a product produced by Kyoeisha Chemical Co., Ltd., and its brand is FLOWLEN G-700AMP, which is a modified polymer containing hydroxyl 2 -Amino-2-methyl-1-propanol salt, the solid content of which is 40-50% by mass; the multifunctional amine additives 0.5%, which is a product produced by the Dow Company of the United States, and its brand is AMP-95; Ionic wetting agent 0.3%, produced by Clariant, its brand is LCN 070, it is an alkyl polyoxyethylene ether, its effective substance content is 100%, HLB value is 13; titanium dioxide 10% , Is a product produced by DuPont of the United States, its brand is R902, which is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com