Composite material capable of bonding with metal and preparation method thereof

A composite material and metal bonding technology, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, non-polymer adhesive additives, etc., can solve the problem of poor chemical solvent resistance and reduced bonding force between metal and plastic etc. to achieve good chemical solvent resistance and heat resistance stability, low shrinkage, excellent heat resistance and strong acid and alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

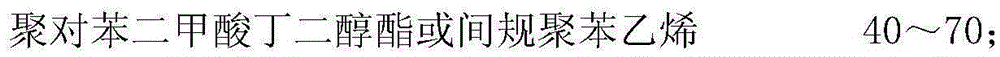

Method used

Image

Examples

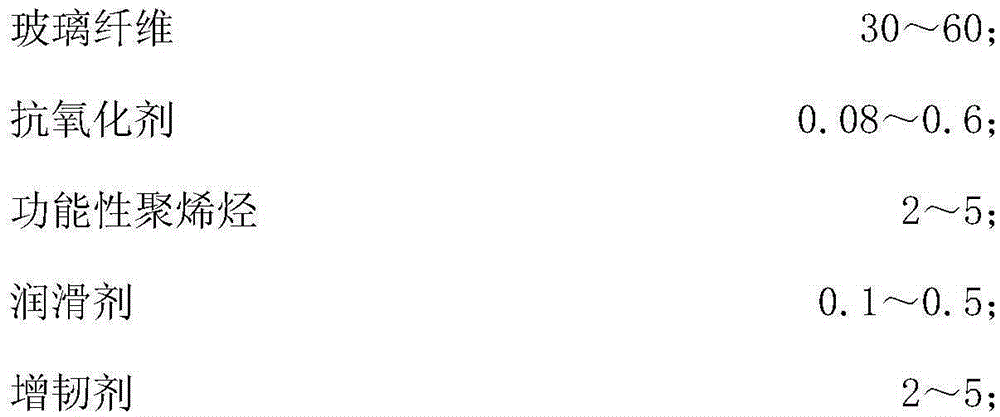

Embodiment 1

[0033] (1) 55 parts of polybutylene terephthalate, 0.3 parts of antioxidant, 5 parts of functional polyolefin 1, 3 parts of toughening agent and 0.3 part of lubricant are taken by weighing 55 parts of polybutylene terephthalate with a crystallinity of 85%;

[0034] (2) Put the above components into the mixer in proportion and mix for 20 minutes;

[0035] (3) Put the mixed raw materials of step poly(2) into a twin-screw extruder, weigh 40 parts of glass fiber side feed, melt extrude, and granulate;

[0036] Among them, the temperature of each temperature control zone of the twin-screw extruder, the temperature of temperature control zone 1-2 is 200-260°C; the temperature of temperature control zone 3-4 is 200-260°C; the temperature of temperature control zone 5-6 is 200°C ~260℃; the temperature of temperature control zone 7-8 is 200~260℃; the temperature of temperature control zone 9-10 is 200~260℃.

Embodiment 2

[0038] (1) 55 parts of polybutylene terephthalate, 0.3 parts of antioxidant, 2.5 parts of functional polyolefin 1, 2.5 parts of functional polyolefin 2, 3 parts of toughening agent and 0.3 parts lubricant;

[0039] (2) Put the above components into the mixer in proportion and mix for 20 minutes;

[0040] (3) Put the mixed raw materials of step poly(2) into a twin-screw extruder, weigh 40 parts of glass fiber side feed, melt extrude, and granulate;

[0041] Among them, the temperature of each temperature control zone of the twin-screw extruder, the temperature of temperature control zone 1-2 is 200-260°C; the temperature of temperature control zone 3-4 is 200-260°C; the temperature of temperature control zone 5-6 is 200°C ~260℃; the temperature of temperature control zone 7-8 is 200~260℃; the temperature of temperature control zone 9-10 is 200~260℃.

Embodiment 3

[0043] (1) Weigh 55 parts of syndiotactic polystyrene, 0.3 part of antioxidant, 2.5 parts of functional polyolefin 1, 2.5 parts of functional polyolefin 3, 3 parts of toughening agent and 0.3 part of lubricant;

[0044] (2) Put the above components into the mixer in proportion and mix for 20 minutes;

[0045] (3) Put the mixed raw materials of step poly(2) into a twin-screw extruder, weigh 40 parts of glass fiber side feed, melt extrude, and granulate;

[0046] Among them, the temperature of each temperature control zone of the twin-screw extruder, the temperature of temperature control zone 1-2 is 200-260°C; the temperature of temperature control zone 3-4 is 200-260°C; the temperature of temperature control zone 5-6 is 200°C ~260℃; the temperature of temperature control zone 7-8 is 200~260℃; the temperature of temperature control zone 9-10 is 200~260℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com