Combustion gas feeding and ignition device for a gas engine

A technology of gas engine and ignition device, which is applied to gaseous engine fuel, combustion engine, internal combustion piston engine, etc., can solve the problems of pressure rise, inability to prevent fire off, emission, etc., so as to reduce the emission of harmful substances and reduce the main Gas dead zone, optimized combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

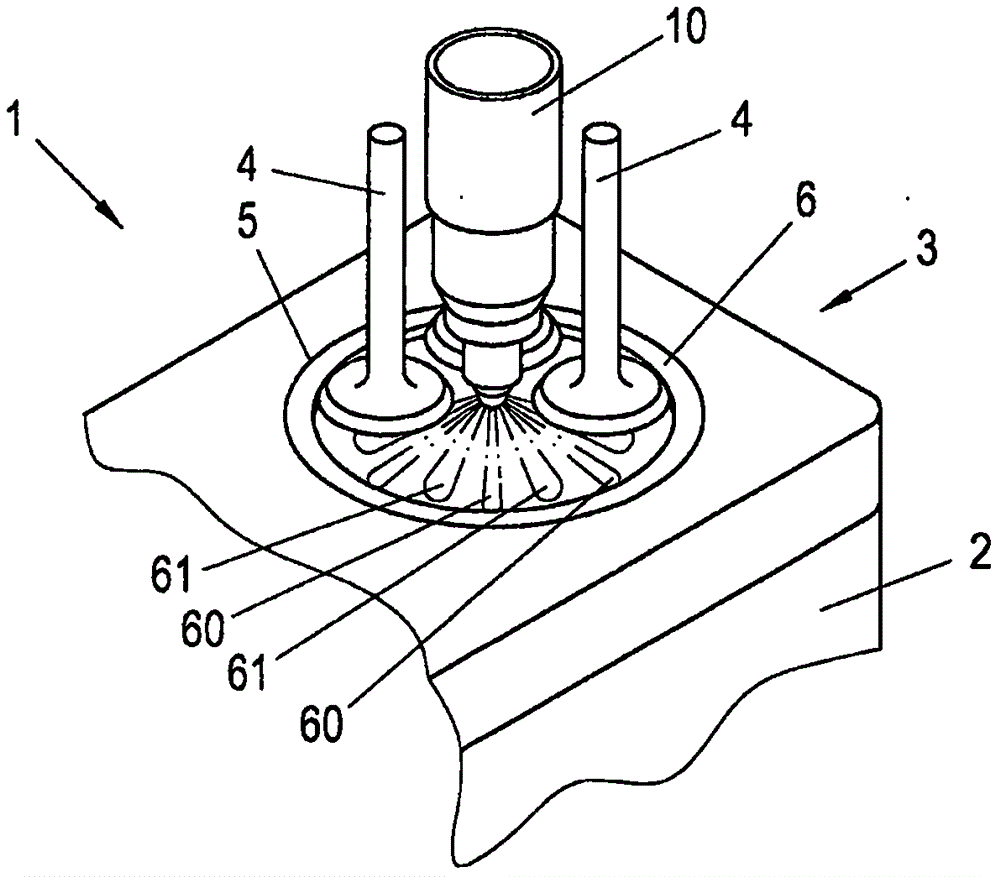

[0033] figure 1 Shown is a part of a gas engine 1 comprising a cylinder block 2 and a only schematically indicated cylinder head 3 and valves 4. A cylinder 5 is arranged in the cylinder block 2 in which a piston 6 can reciprocate. This basic design and function of a piston internal combustion engine is already known, so it will not be described in detail here. In the cylinder head 3 there is also a gas supply and ignition device 10 according to the invention, with which the main gas is supplied and ignited The device is supplied to the main combustion chamber 11 of the cylinder 5, and the gas supply and ignition device is used to ignite combustion in the main combustion chamber 11, which will be described in detail below.

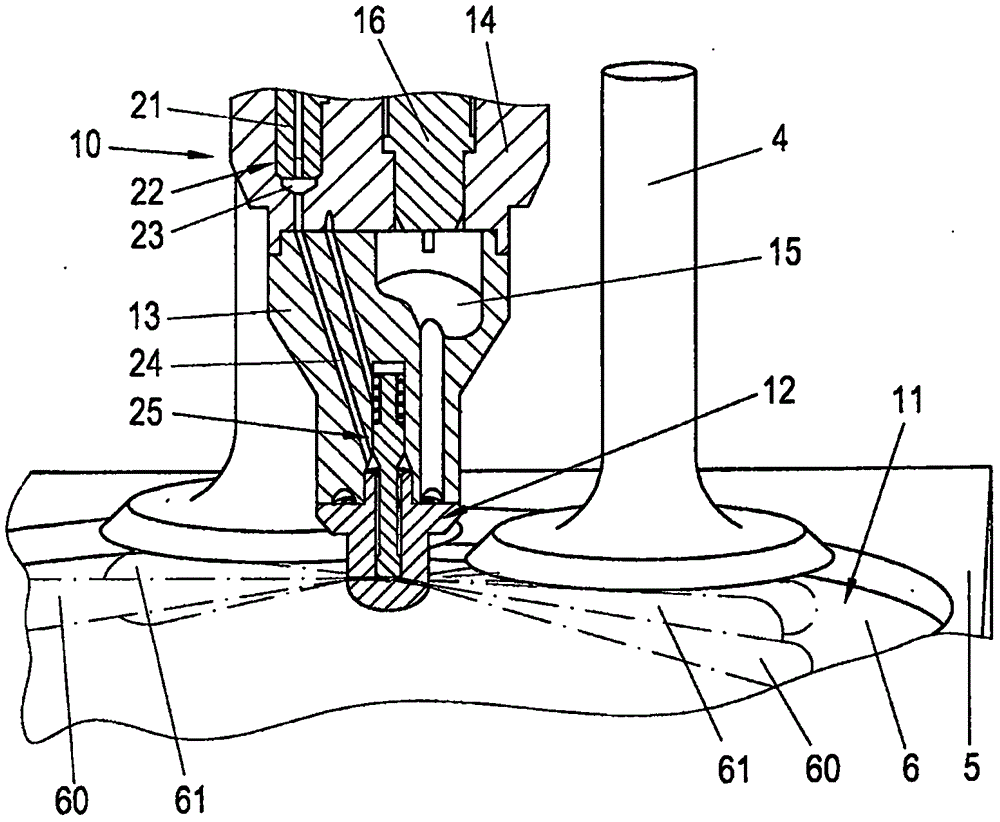

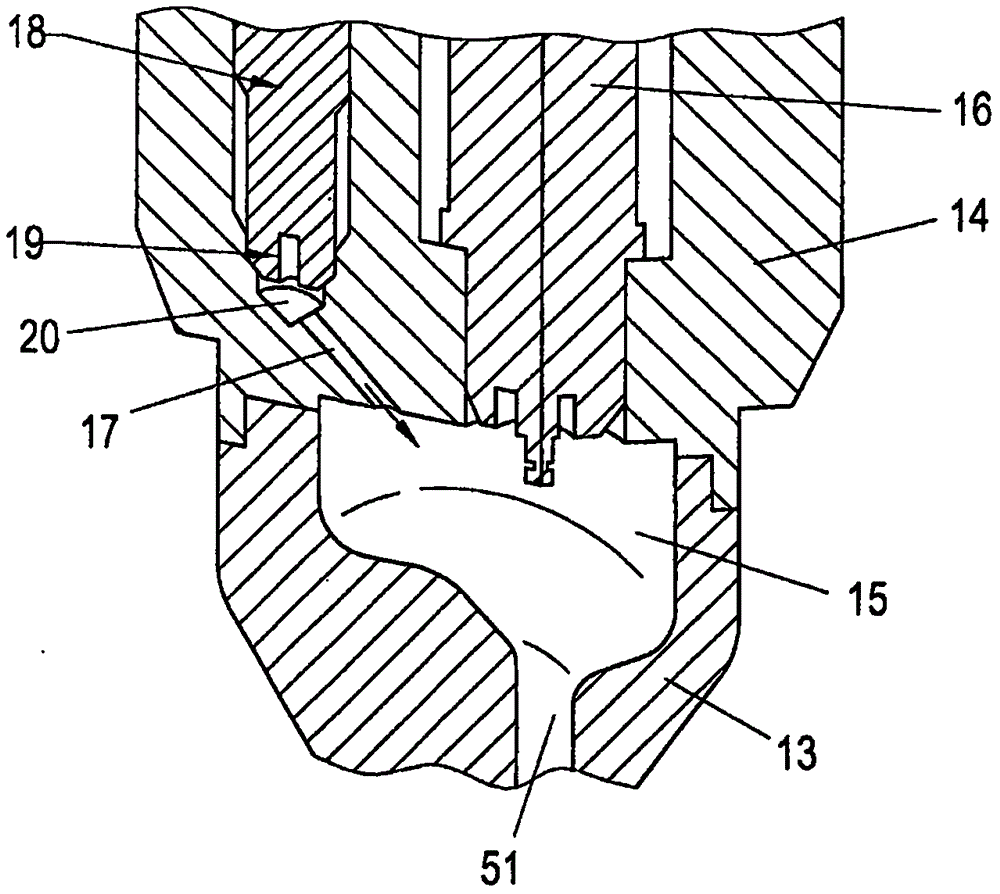

[0034] figure 2 An enlarged sectional view showing the cylinder 5 together with the gas supply and ignition device 10 and its main components. The gas supply and ignition device 10 is arranged in the cylinder head 3 in such a way that it protrudes into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com